Propellant surplus measuring system and method

A measurement system and propellant technology, applied in the field of propellant residual quantity measurement system, can solve the problems of limited measurement times, immaturity, poor versatility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

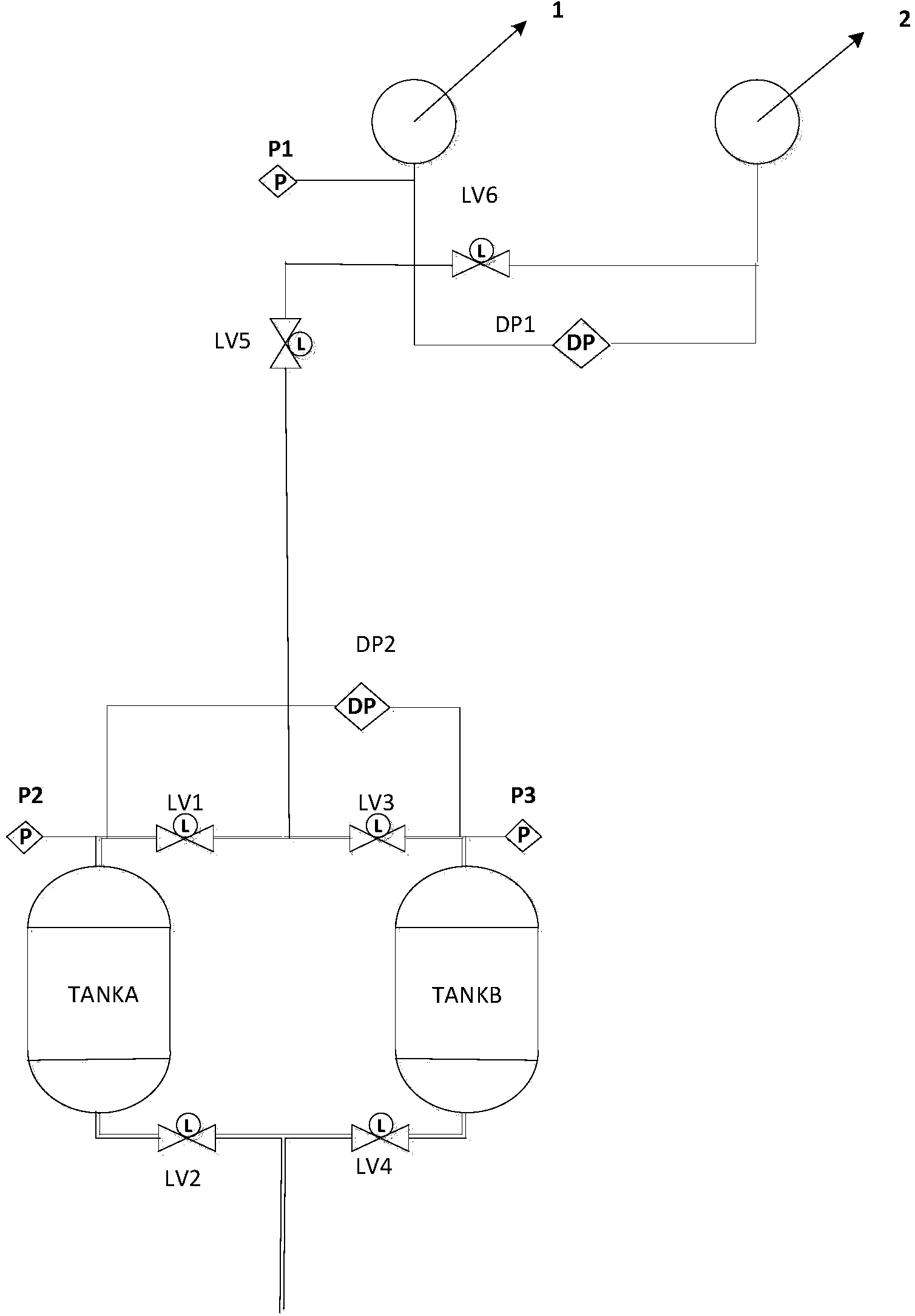

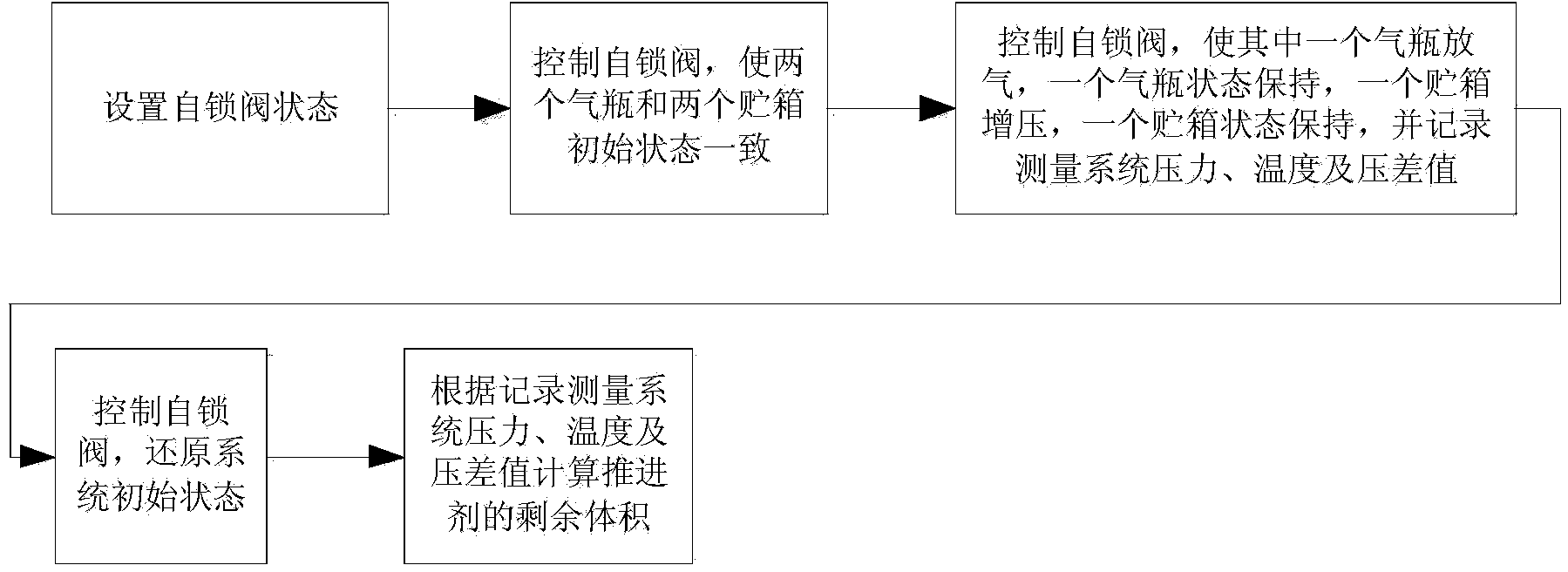

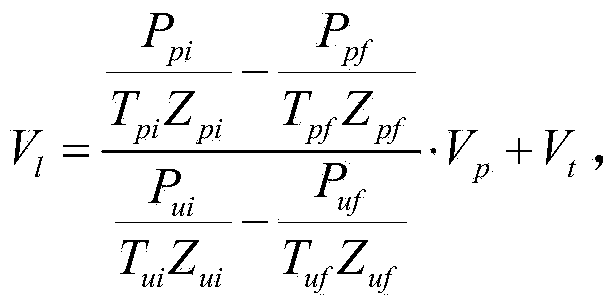

[0029] The system and method for measuring the remaining amount of propellant according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

[0030]At present, most of the technologies used for propellant remaining measurement in microgravity rely on the bookkeeping (BK) method of propellant consumption and the basic propellant thermodynamic measurement method (PVT method). It is ±1.63% (the total volume of the storage tank), but the actual error is about 3%. For this reason, on the basis of the existing platform, those skilled in the art adopt the gas injection method as the main measurement method, and the modified PVT method and BK method as the auxiliary measurement methods, and the measurement accuracy can reach ±0.8% (total volume of the storage tank) . However, the measurement accuracy still needs to be improved, and the number of measurements is extremely limited, which can only reach less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com