Anti-upwarp device for shear box

A box anti-warping technology, which is applied in the field of scissor box anti-warping device, can solve the problems of affecting test accuracy, scissor box upward warping, tester measurement accuracy reduction, etc., to achieve light and simple design, improve test accuracy, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

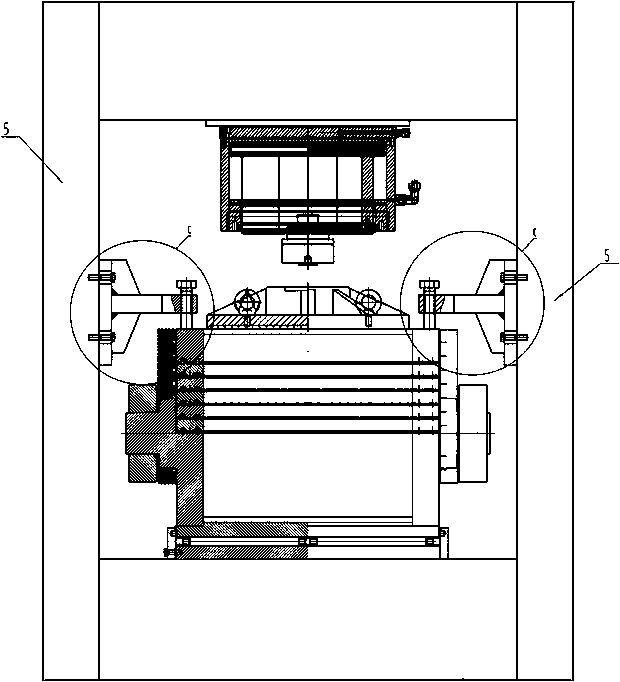

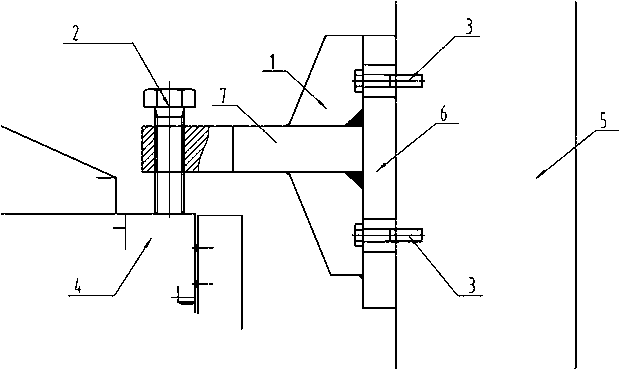

[0012] according to Figure 1-2 It can be seen that the present invention is symmetrically installed on the shear tester, including the anti-warping device support 1, and the anti-warping device support 1 includes a base 6 and an anti-warping block 7 vertically welded in the middle of the base 6, between the base 6 and the anti-warping block 7 Reinforcing ribs are arranged between them, the base 6 is fixed on the side beam through bracket fixing screws, the anti-warping block 7 is horizontally fixed on the top layer stacking ring 4 through the anti-warping locking screw 2, and there is a gap between the anti-warping block 7 and the top layer stacking ring 4 .

[0013] The reinforcing rib of the present invention is a section of right-angled trapezoidal connection surface arranged at the right-angle connection between the base 6 and the anti-warping block 7 .

[0014] Design principle of the present invention:

[0015] The best and easiest way to prevent the scissor box from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com