A piezoelectric power generation device and method for capturing vertical wave energy

A piezoelectric power generation technology in the vertical direction, applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. High, uneven strain distribution and other problems, to achieve the effect of strong practicability, convenient use, and simple implementation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

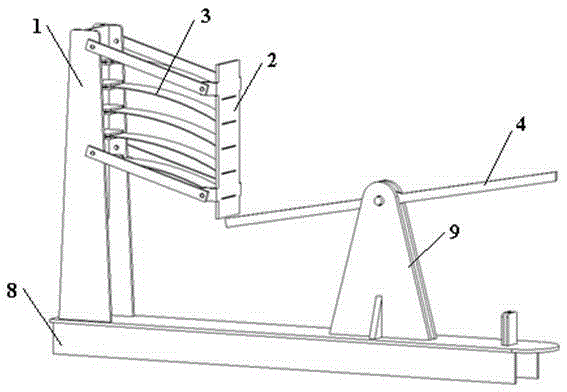

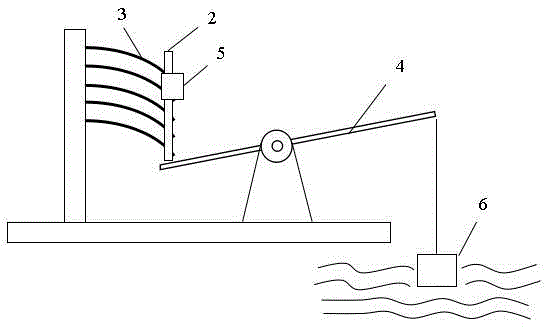

[0022] Specific implementation mode one: as Figure 1-2 As shown, the present invention provides a piezoelectric power generation device for capturing wave energy in the vertical direction, including a bracket 1, a clamping structure 2, a composite piezoelectric bistable plate 3 bonded with a piezoelectric material 7, a support arm 4, and a float 6. Support 8, base 9. The support 1 and the base 9 are fixed on the support 8, one end of the clamping structure 2 is fixed on the support 1, and the composite piezoelectric bistable plates 3 are clamped in parallel at equal intervals on the fixed end and the free end of the clamping structure 2 Above, a counterweight mass 5 is installed at the free end of the clamping structure 2, so that the composite piezoelectric bistable plate 3 is initially bent downward. The support arm 4 is used as a lever, the middle part is connected with the base 9, one end is tied with a float 6, and the other end is offset against the free end of the cla...

specific Embodiment approach 2

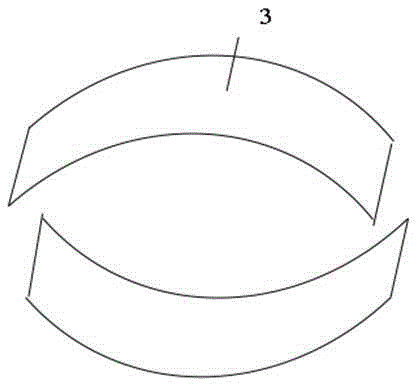

[0024] Embodiment 2: This embodiment provides a composite piezoelectric bistable plate, which is flat and rectangular before curing, and arc-shaped after curing. After curing, it has two stable shapes, such as image 3 As shown, the top is the first steady state, and the bottom is the second steady state. The composite piezoelectric bistable plate described in this embodiment adopts composite material and metal hybrid layering, solidifies at the curing temperature of the composite material, and can form an arc-shaped bistable effect due to residual thermal stress after cooling.

[0025] The layering is composed of symmetrical layering of composite materials and hybrid layering of metal composite materials, and both sides of the symmetrical layering of composite materials are hybrid layering layers of metal composite materials with symmetrical sizes.

[0026] Described composite material symmetrical layup is 90 ° and 0 ° composite material symmetrical layup, wherein 90 ° compos...

specific Embodiment approach 3

[0032] Specific implementation mode three: the specific layering method of the composite piezoelectric bistable plate in this implementation mode is as follows Figure 5 As shown, the upper part of the figure is the top view of the layup, and the lower part is the section view of the layup in different regions. The layup is divided into two regions, and the I region is a symmetrical layup of fiber composite materials, in which the 90° fiber composite material layer 10 is on the outside, and the 0° fiber composite material layer 11 is in the middle, such as [90 2 / 0 2 / 90 2 ]; II region is the metal fiber mixed region, the same 90 ° fiber composite material layer 10 is on the outside, and the metal Al layer 12 is in the middle, such as [90 2 / Al / 90 2 ]. It should be noted that in order to keep the thickness consistent, the thickness of the 0° fiber composite layer in the I region should be the same as that of the metal Al in the II region, and the 90° fiber composite layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com