Thin electronic ballast and manufacturing method of thin electronic ballast

A technology for electronic ballasts and manufacturing methods, applied to electric light sources, electrical components, lighting devices, etc., capable of solving problems such as additional breakage, poor contact or short circuit, complicated process, and increased manufacturing costs of electronic ballasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

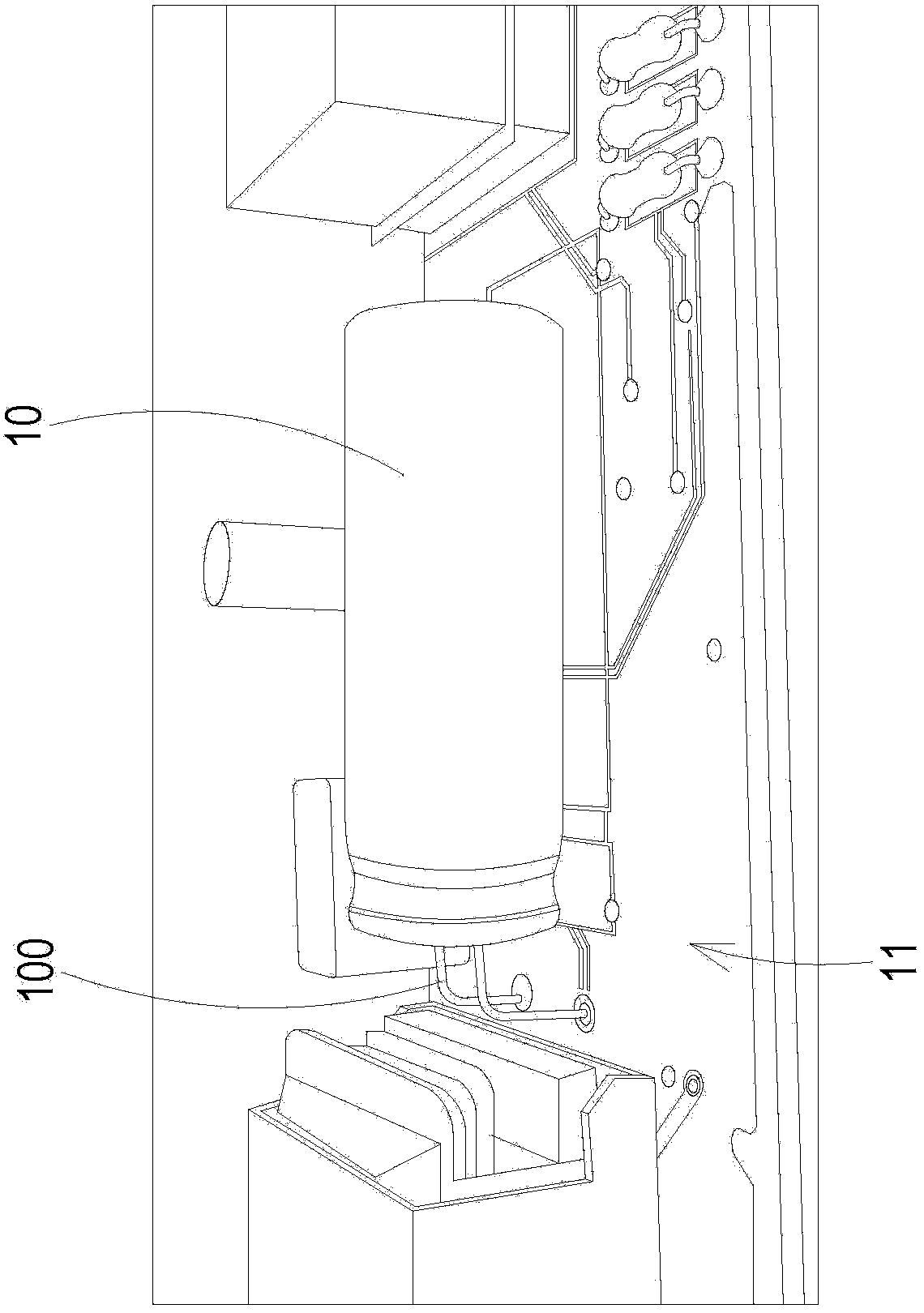

Image

Examples

Embodiment Construction

[0047] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different ways without departing from the scope of the present invention, and the descriptions and drawings therein are used for illustration in nature rather than for limiting the present invention .

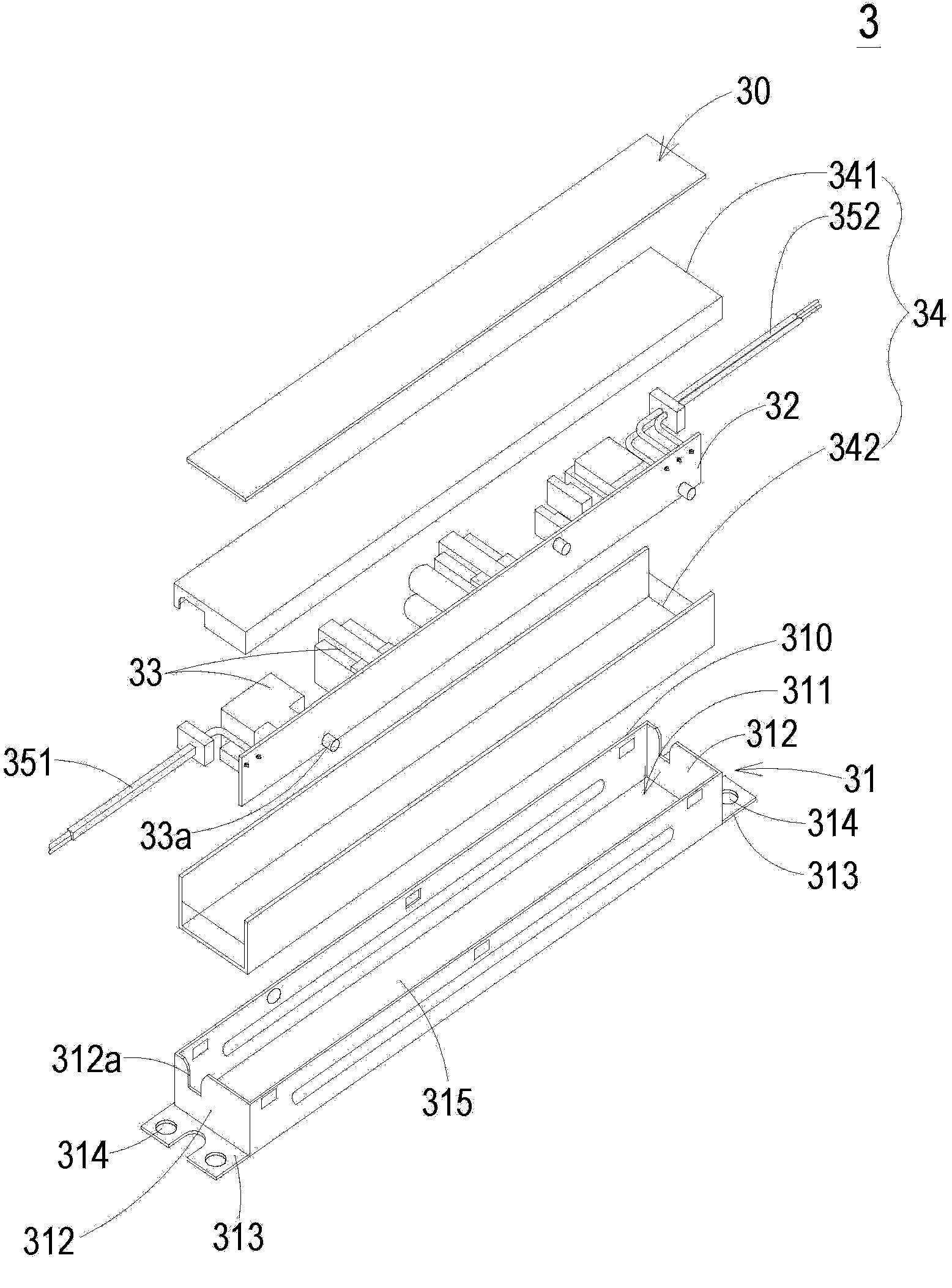

[0048] see image 3 , which is a schematic structural view of a thin electronic ballast according to a preferred embodiment of the present invention. As shown in the figure, the thin electronic ballast 3 of the present invention is composed of a metal shell 31, a circuit board 32, and a metal upper cover 30. The metal shell 31 has an opening 310 and an accommodating space 311, and the opening 310 It communicates with the accommodating space 311. The circuit board 32 is provided with a plurality of electronic components 33, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com