Vacuum system for thin film evaporation-rectification coupled device

A rectification coupling and vacuum system technology, applied in the field of vacuum systems, can solve the problems of reducing the vacuum degree of the system, affecting the emulsification of vacuum pump oil, and affecting the stability of vacuum pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

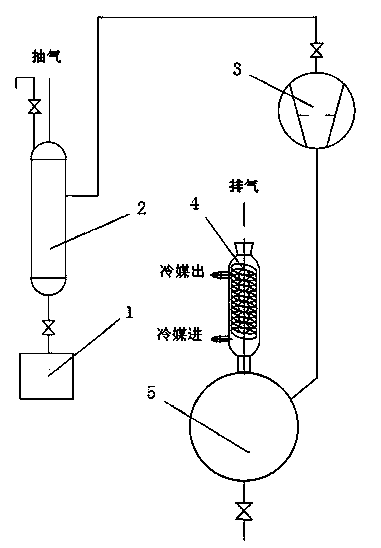

[0015] Such as figure 1 As shown, a vacuum system for the coupling equipment system of thin film evaporation and rectification includes a vacuum pump 3, one end of the vacuum pump 3 is connected to the buffer tank 2 through a pipeline, and the buffer tank 2 is connected to the coupling equipment system 1 of thin film evaporation and rectification through a pipeline, The other end of the vacuum pump 3 is connected to the receiver 5 through a pipeline, and the receiver 5 is provided with a condenser 4 . The vacuum pump 3 is a dry screw vacuum pump. Both the condenser 4 and the receiver 5 are made of glass. The pressure of the vacuum system is 5Pa-2000Pa. The top of the condenser 4 is an open structure and is connected to the atmosphere. Coupling equipment system 1 for thin film evaporation and rectification is the coupling equipment system for thin film evaporation and rectification described in the Chinese utility model patent with application number 201320122760.0 titled "A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com