Production method of novel vacuum insulated panel

A technology for vacuum insulation panels and production methods, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high material cost, non-environmental protection, high energy consumption, etc., achieve low price, reduce raw material cost, Effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

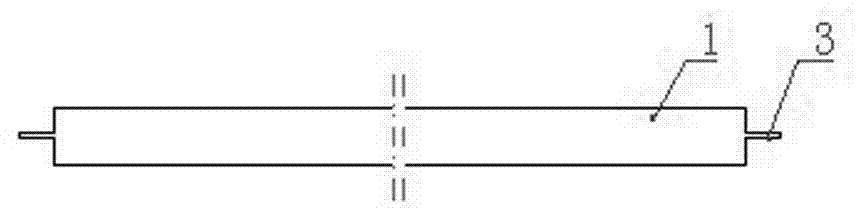

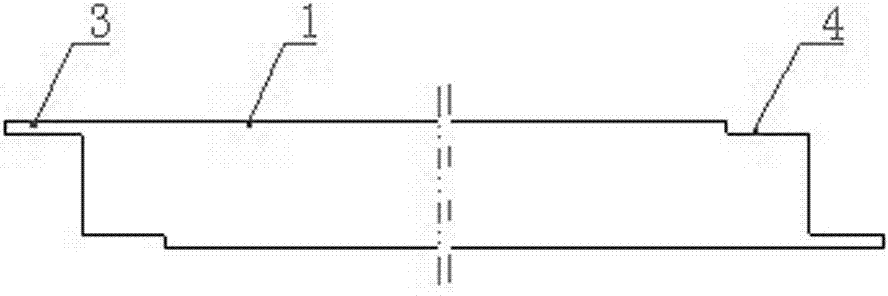

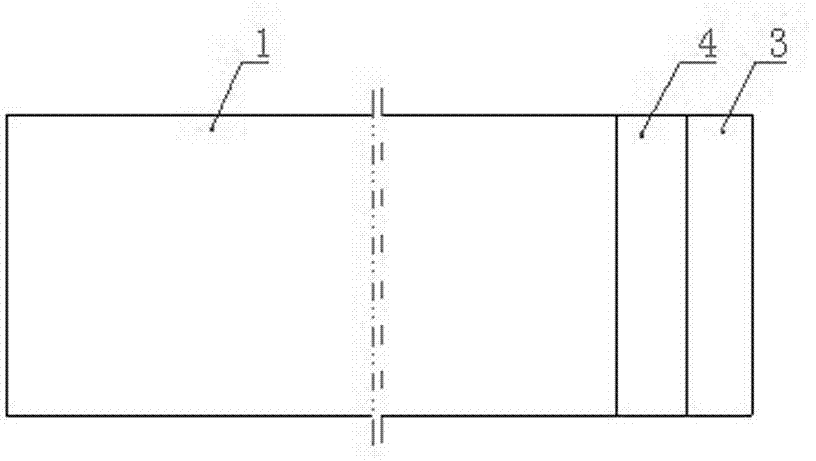

Image

Examples

Embodiment Construction

[0026] The invention discloses a novel production method of vacuum heat insulation panels, a production method of novel vacuum heat insulation panels. The core material is put into a high-barrier gas film bag, and sealed after vacuuming. It is characterized in that the composition of the core material and The parts by weight are: microsilica powder 10-14, fumed silica 15-18, white carbon black 5-8, superfine natural silica powder 8-10, inorganic fiber 5-7, vacuum stabilizer 1-2 , getter 1-2;

[0027] The manufacturing process includes the following steps:

[0028] (1) Ingredients: Put various materials of the formula into the mixer for full mixing;

[0029] (2) Drying: Dry the evenly stirred mixture, and control the drying temperature at 100-120°C. During the drying process, measure the moisture content of the mixture every 8 minutes until the moisture content of the mixture reaches 0.5 % below, stop drying;

[0030] (3) Bag making and filling: Put the dried mixture into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com