Cone crusher

A technology of cone crusher and main machine, which is applied in non-rotational vibration suppression, grain processing and other directions, can solve the problems of dismantling, large force and high impact frequency, and achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

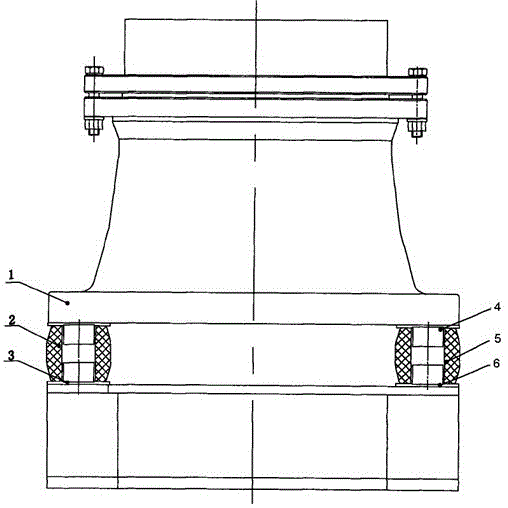

[0018] A cone crusher, comprising a chassis 1, a working host 3 and a rubber damping device 2, the working host 3 is connected to the rubber damping device 2, and the rubber damping device 2 is connected to the chassis 1, and the rubber damping device 2 includes The upper guide 4, the rubber damping spring 5 and the lower guide 6, the upper guide 4 is connected to the working host 3, the lower guide 6 is connected to the chassis 1, and the rubber damping spring 5 is between the upper guide 4 and the lower guide 6 Between, the rubber damping device is four groups, the rubber damping spring is set on the outside of the upper guide and the lower guide, the upper guide and the lower guide are guide sleeves, the described The rubber damping spring is embedded in the inside of the upper guide and the lower guide.

[0019] The bottom frame is placed directly on the ground, without anchor bolts, and it is not necessary to build a large and solid reinforced concrete foundation like oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com