Solder strip delivery mechanism of solar cell serial welding machine

A technology of solar cells and stringers, which is applied to circuits, tin feeding devices, electrical components, etc., can solve the problems of unreasonable structure of distribution mechanism, easily broken ribbon, and low welding strength, so as to reduce manual intervention time, improve string welding efficiency and welding quality, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

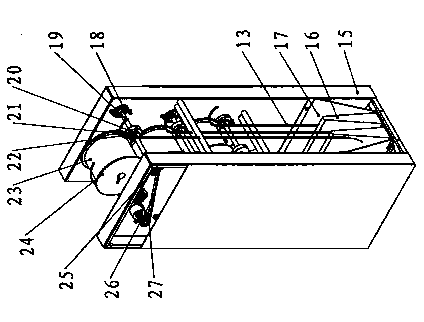

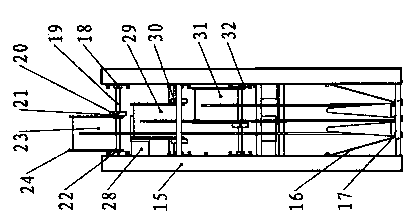

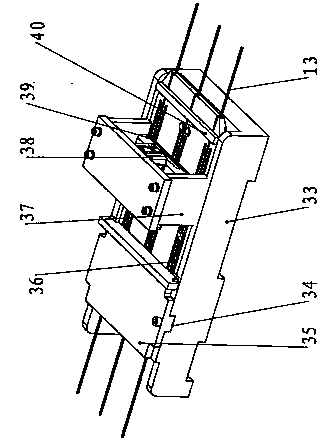

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] An automatic stringer, including an automatic transmission welding platform, an electric control transmission belt for the welding platform is arranged on the automatic transmission welding platform, and an automatic solar battery sheet automatic feeding system is arranged on one side of the automatic transmission welding platform, The solar cell automatic feeding system is equipped with a cell positioning mechanism and a solar cell feeding mechanism. The welding mechanism and the welding ribbon cutting mechanism are respectively provided between the automatic transmission welding platform and the welding ribbon delivery mechanism, and the welding ribbon 13 set in the welding ribbon delivery mechanism is cut off by the welding assistance mechanism and the welding ribbon in turn. The mechanism is welded and connected with the solar cells installed on the welding position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com