A hot-press assembly device and a hot-press assembly method for a balance shaft

An assembly device and balance shaft technology, which is applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of high error rate, many operators, and low clamping strength of the balance shaft body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] see Figure 1 to Figure 17 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

[0056] A balance shaft hot-press assembly device of the present invention is used for hot-press assembling a balance shaft body and a sprocket, and the hot-press assembly becomes a balance shaft.

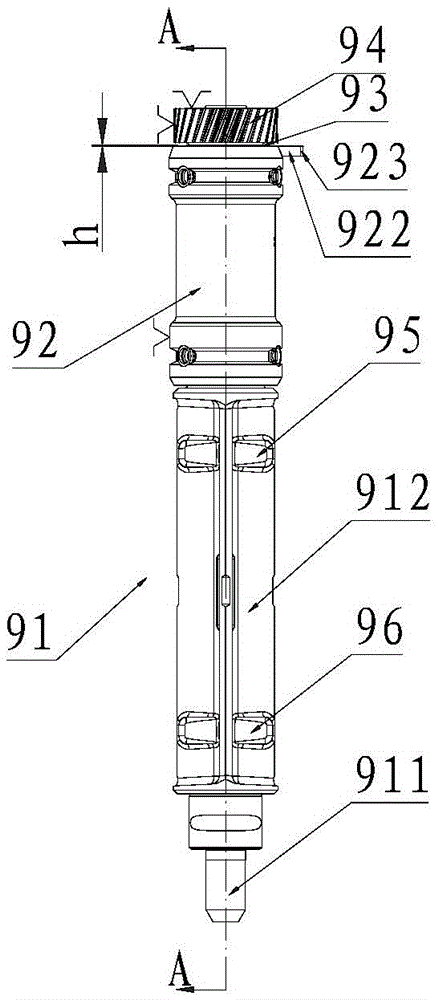

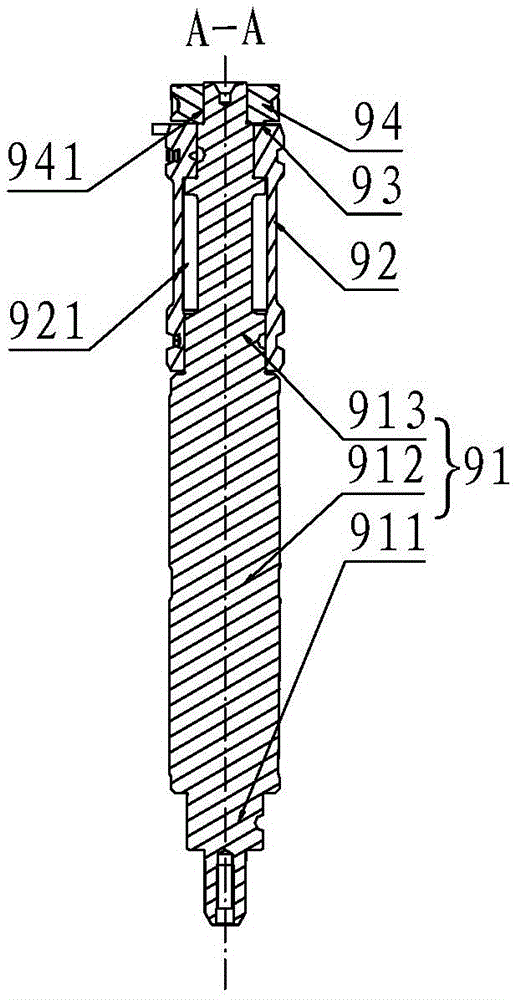

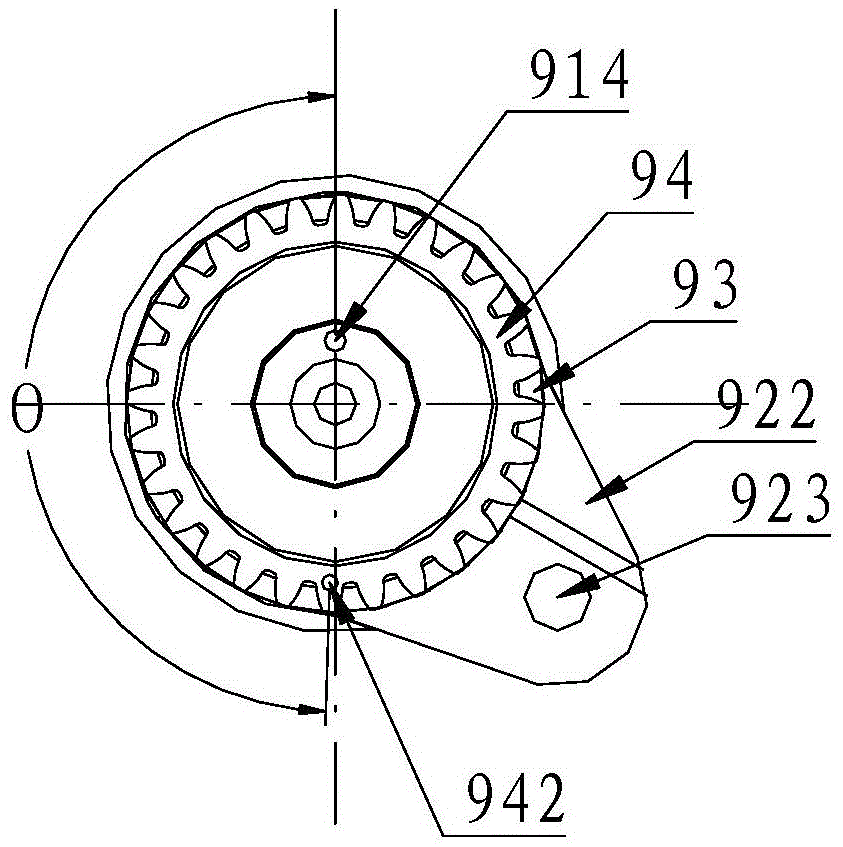

[0057] see Figure 1 to Figure 6 , the balance shaft used on the automobile, including a balance shaft body 91, a sleeve 92, a spacer 93 and a sprocket 94. Wherein, the balance shaft body 91 includes a shaft bottom 911 , a shaft middle 912 and a shaft top 913 . The cross-sectional shape of the shaft middle part 912 is a semicircle, because the cross-sectional shape of the shaft middle part 912 is a semicircle, so the outer peripheral surface of the shaft middle part 912 is surrounded by a curved surface and a plane, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com