Printing head of three-dimensional printer

A three-dimensional printer and print head technology, applied in the field of print heads, can solve the problems of affecting printing speed and accuracy, single model color, unfavorable popularization and use, etc., and achieve the effect of improving printing accuracy and speed, improving printing quality and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

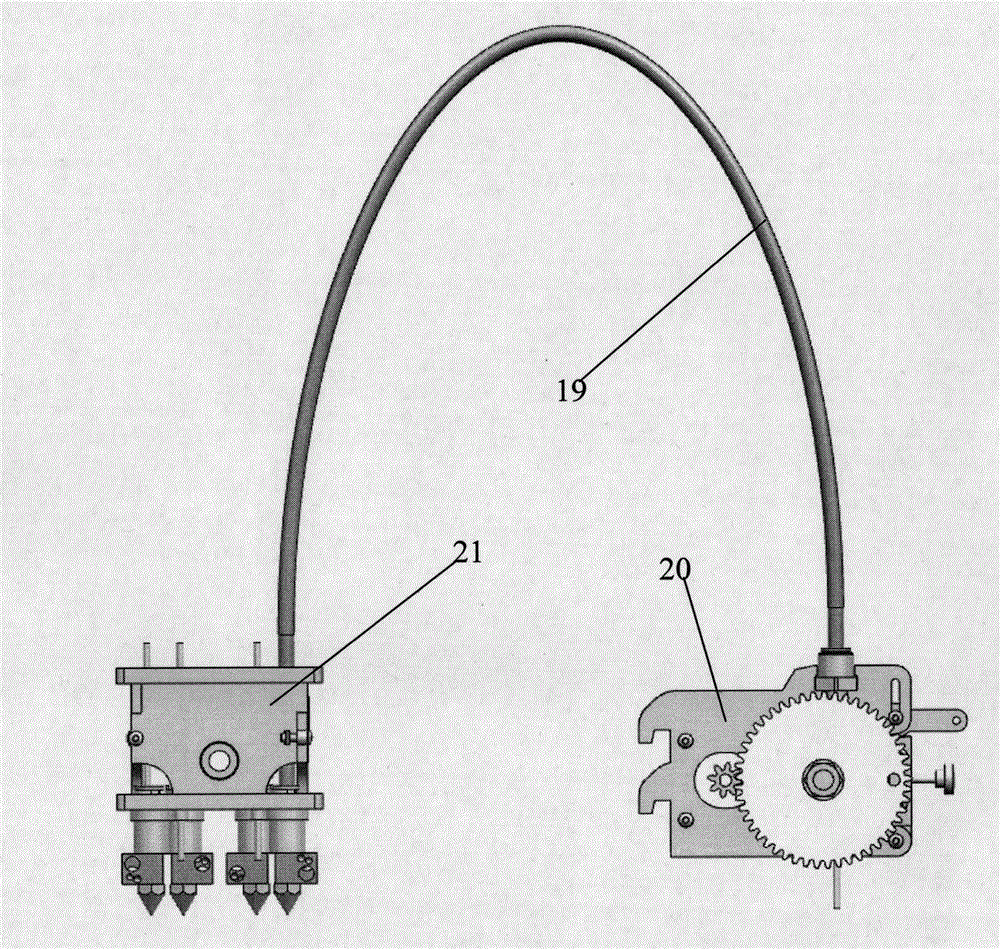

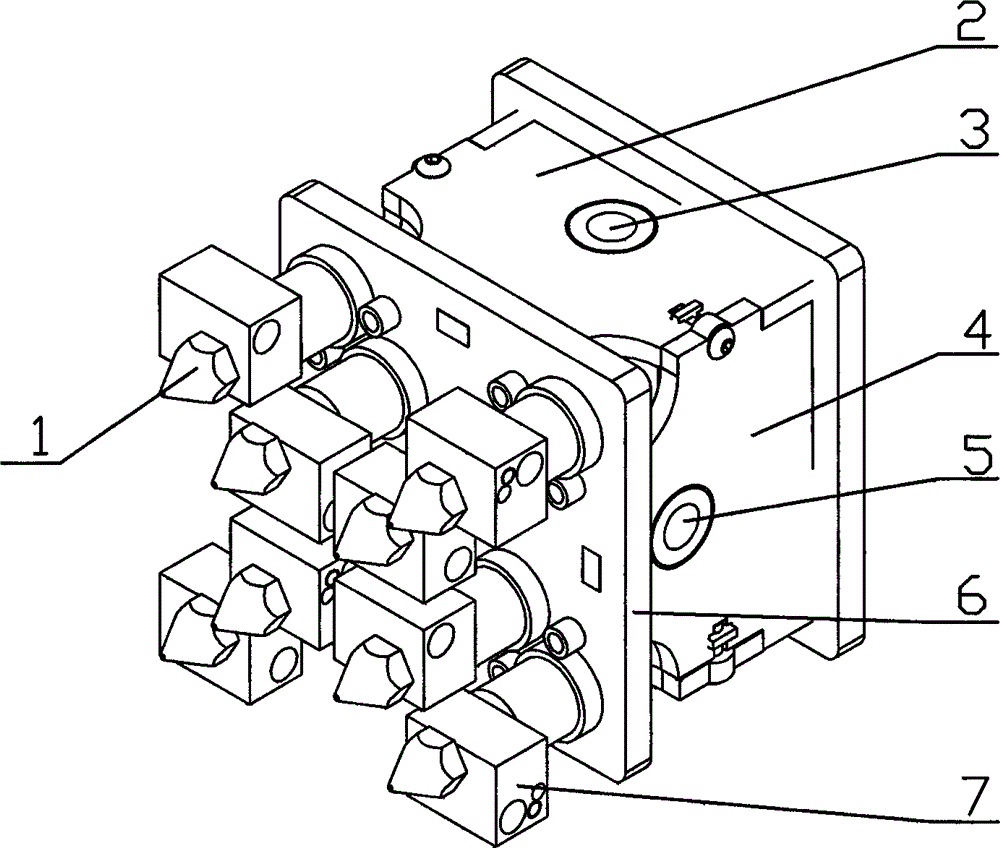

[0020] Such as Figure 1-Figure 4 As shown, this embodiment includes a heating head 21 and a wire feeding mechanism 20. The heating head 21 includes 8 sub-heating heads 1, connecting plates 6, front and rear fixed baffles 2 and left and right fixed baffles 4. The sub-heating heads 1 Arranged in a matrix on the connecting plate 6 to form an integrated 3D printer nozzle, the advantage of the matrix arrangement is that the mutual positions of the nozzles are stable, and the movement of the motors in the X and Y directions can be well compensated. The movement error of the heating head in the XY plane.

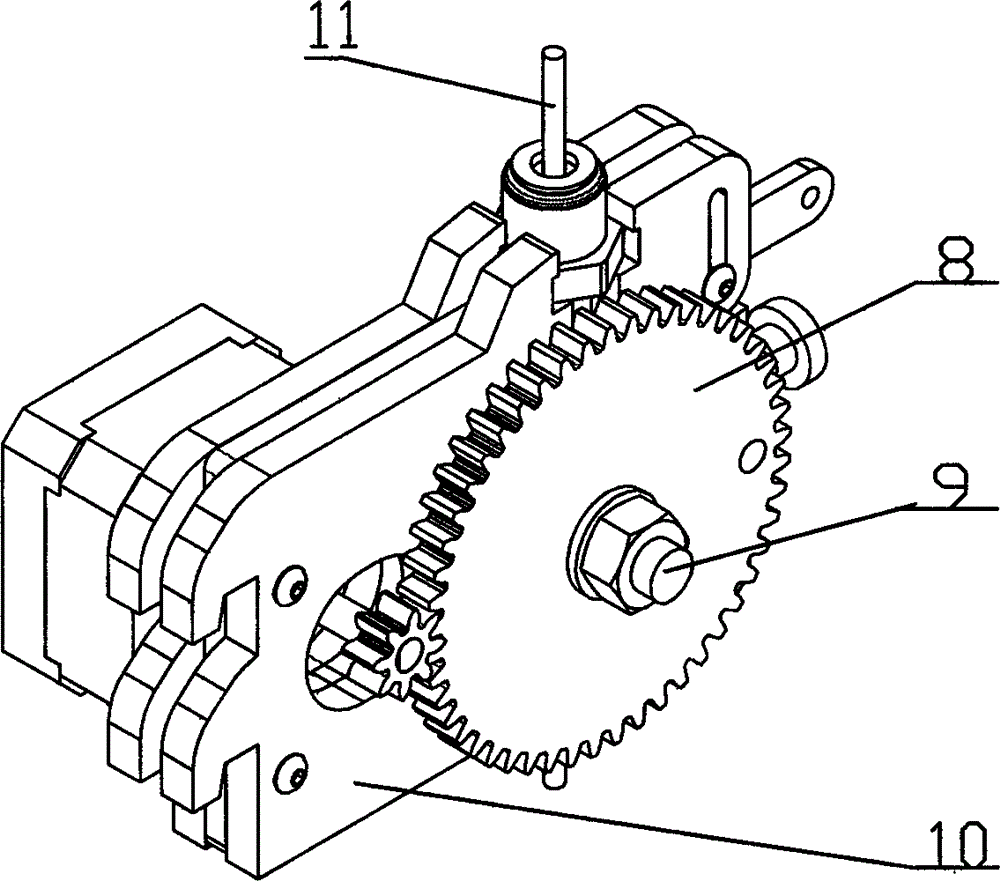

[0021] The feed port of the sub-heating head 1 is connected to the feed port of the wire feeding mechanism 20 at the far end through a sleeve 19 .

[0022] Another example figure 2 As shown, the sub-heating head 1 is provided with a sensor fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com