A kind of preparation method of titanium dioxide photocatalyst coating

A technology of titanium dioxide and photocatalyst, applied in the direction of coating, layered products, etc., can solve the problems of poor film adhesion, affect the photocatalytic properties of TiO2, shorten the service life, etc., achieve strong self-cleaning ability, long service life and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

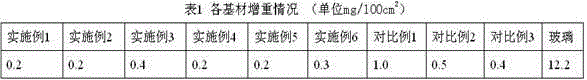

Examples

Embodiment 1

[0022] (1) Weigh 5 grams of TiO 2 Add nanometer powder to 1L solution containing water, ethanol, and glacial acetic acid (the volume ratio of water: ethanol: glacial acetic acid is 1 / 1 / 0.1) and grind to obtain a uniform translucent suspension without precipitation.

[0023] (2) Apply the above-mentioned suspension to the surface of the cleaned glass by spraying to form a nanometer layer, and dry it under air conditions.

[0024] (3) heat-treat the substrate in the above step (2) at 400° C. for 10 h under air conditions, and then cool to room temperature to form a photocatalyst coating on the surface of the substrate. The obtained coating has a smooth surface, uniform thickness, good transparency, and a thickness of 300 nanometers.

Embodiment 2

[0026] (1) Weigh 5 grams of metatitanic acid, add 1L of water, ethanol, glacial acetic acid (the volume ratio of water: ethanol: glacial acetic acid is 1 / 2 / 0.1) and grind to obtain a uniform translucent suspension.

[0027] (2) Apply the above-mentioned suspension to the surface of the cleaned ceramic glazed tile by inkjet printing method to form a nanometer layer, and dry it under air condition.

[0028] (3) heat-treat the substrate in the above step (2) at 550°C for 1 hour under air conditions, and form a photocatalyst TiO on the surface of the substrate after cooling to room temperature 2 coating. The obtained coating has a smooth surface, uniform thickness, good transparency, and a thickness of 100 nanometers.

Embodiment 3

[0030] (1) Weigh 15 grams of TiO 2 Add 0.5L of nano powder to a solution containing water, ethanol, and glacial acetic acid (the volume ratio of water: ethanol: glacial acetic acid is 1 / 1 / 0.2) and grind to obtain a uniform translucent suspension without precipitation.

[0031] (2) Apply the above-mentioned suspension to the surface of the cleaned ceramic sanitary ware by spraying to form a nano-layer, and dry it under air conditions.

[0032] (3) heat-treat the substrate in the above step (2) at 600°C for 1 hour under air conditions, and form a TiO2 photocatalyst coating on the surface of the substrate after cooling to room temperature. The obtained coating has a smooth surface, uniform thickness, good transparency, and a thickness of 300 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com