Cargo transfer forklift for train

A technology for transferring forks and goods, applied in the direction of lifting devices, etc., can solve the problems of unfavorable forklift turning, increase the length of the whole vehicle, and increase the length of the whole forklift, so as to achieve flexible and convenient turning, increase the moving stroke, and shorten the overall effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

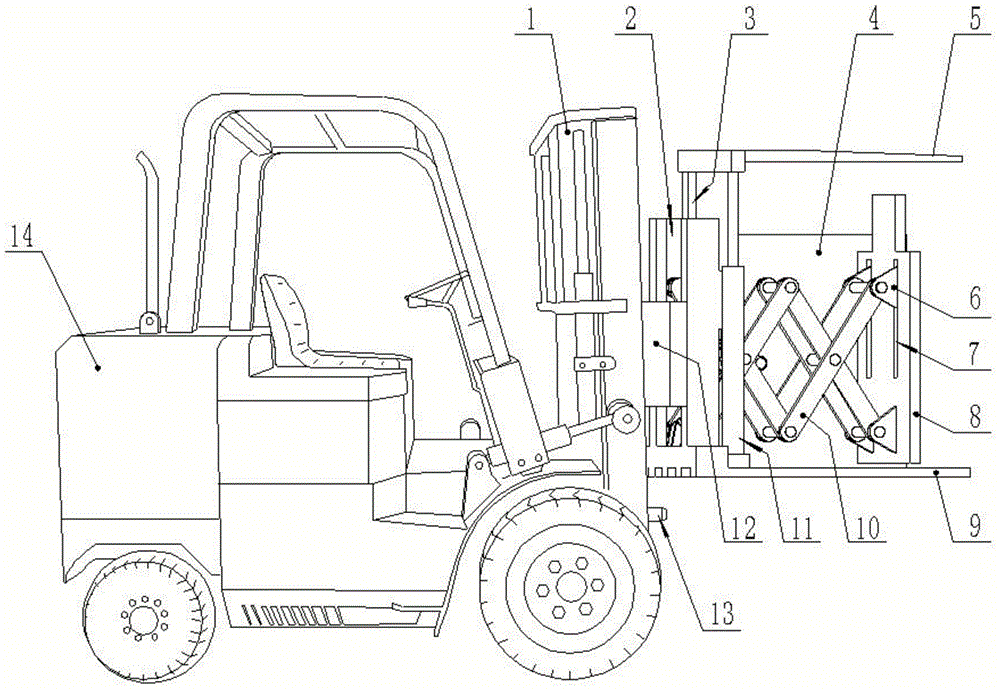

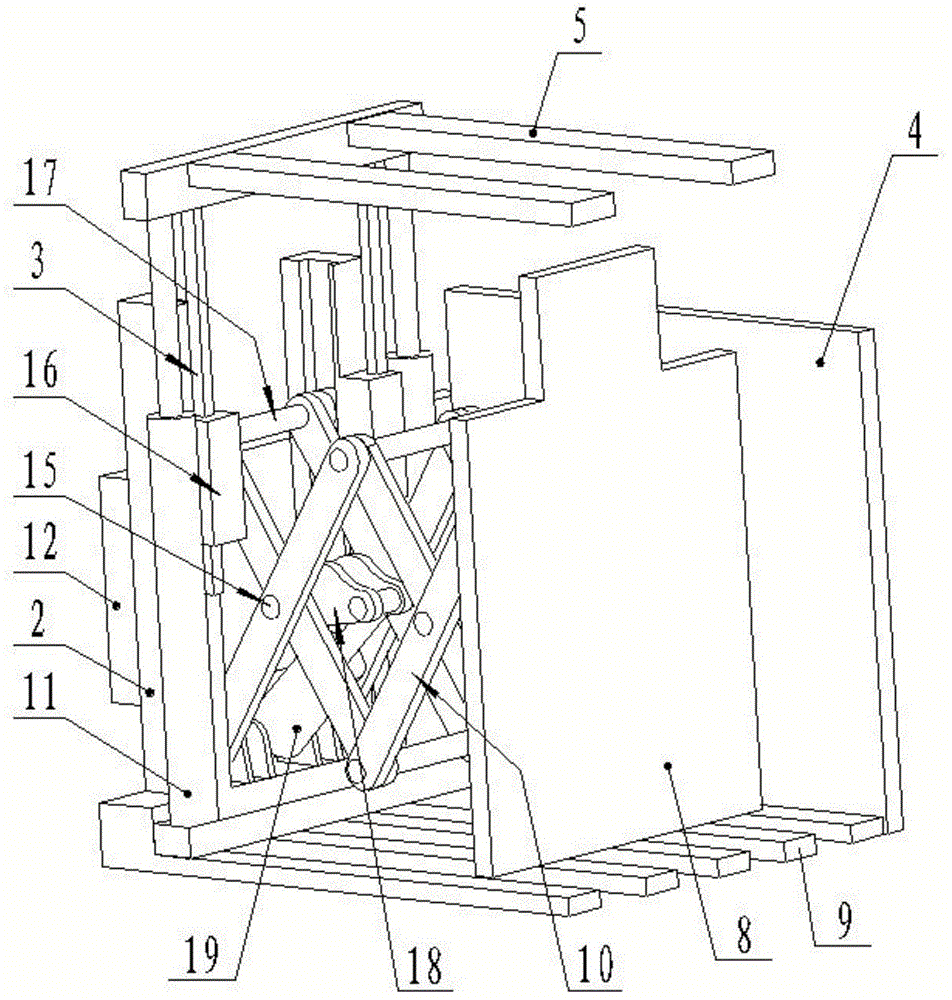

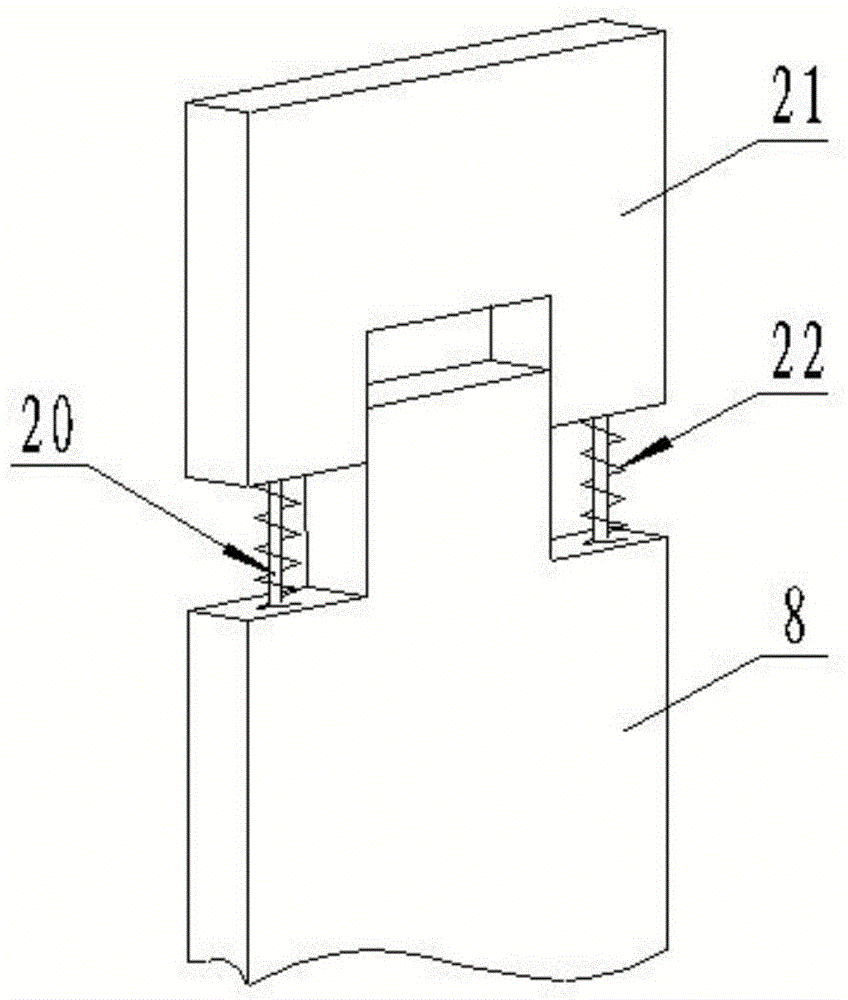

[0013] Such as Figure 1~2 Shown: the front of the forklift body has a lifting device 1, a counterweight 14 is fixed at the rear, and a cargo pushing mechanism is arranged on the lifting device 1; The slewing mechanism 12 connected to the lifting device 1 on the back of the two slide rails 2 is respectively hinged to the two scissor telescopic frames 10 at the rear end of the cargo fork 9 through the lower fork at the rear end, and is hinged to the two scissor telescopic frames through the pin shaft 15. The crank 18 between the 10, the push cylinder 19 hinged to the rear end of the cargo fork 9 and hinged to the crank through the piston rod, and the push plate 8 hinged to the lower fork head of the front end of the two scissor telescopic frames 10 are located on the two slide rails respectively. 2 outer sides and the compression cylinder 11 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com