Purifying power generation system of floor sewage

A power generation system and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, engine components, etc., can solve the problems of large power generation system loss, low power generation efficiency, irregularity, etc., to improve power generation High efficiency, high purification efficiency and sufficient purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

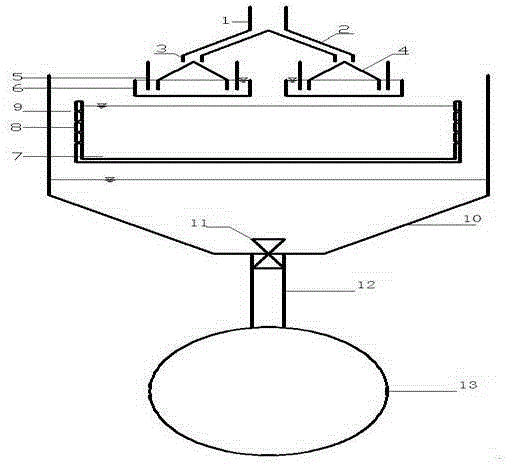

[0023] Below in conjunction with accompanying drawing, the present invention is further described.

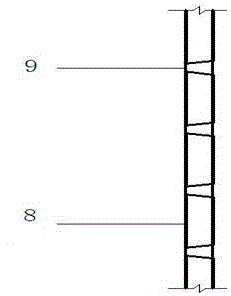

[0024] Such as figure 1 shown, as figure 1 As shown, a floor sewage purification power generation system includes a main water diversion pipe 1, the main water diversion pipe 1 is connected with two water diversion branch pipes 2, and the lower end of the water diversion branch pipe 2 is connected with a vertical diversion pipe 3, and below the diversion pipe 3 is filled with activated carbon. Conical decontamination body 4, under the cone decontamination body 4 there is a flocculation tank 6, below the flocculation tank 6 there is a radial flow sedimentation tank 7, the upper wall of the radial flow sedimentation tank 7 is a seepage wall 8, and the radial flow sedimentation tank 7 There is a sump 10 below, and an infrared valve 11 is located at the bottom of the sump 10 , and the infrared valve 11 is connected to a water turbine 13 through a vertically downward power generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com