Self thermogenesis chemical temperature raising agent for acid thick oil reservoir and use method of agent

A self-generating heat technology for heavy oil reservoirs, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to achieve self-generated heat raising of porous media in reservoirs, achieve good carrying injection effect, temperature sensitive High triggering and heat release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

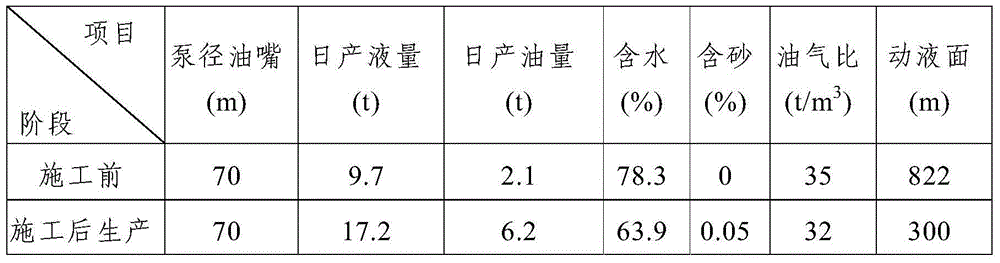

Examples

Embodiment 1

[0037] The self-generating chemical temperature-raising agent for acidic heavy oil reservoirs in this embodiment includes a heat-generating agent and a triggering agent, and the heat-generating agent includes magnesium powder with a particle size not greater than 400 mesh and a coating layer for wrapping the magnesium powder , the triggering agent is a particle size not greater than 400 mesh P 2 o 5 powder, magnesium powder and P 2 o 5 The mass ratio of the powder is 1:1.0, and the coating layer is a paraffin wax coating layer or a magnesium stearate coating layer.

[0038] When the coating layer is a paraffin wax coating layer, the preparation method of the heat generating agent comprises the following steps:

[0039] Step 1. Add paraffin to cyclohexane under stirring conditions at 65°C until completely melted to obtain a coating solution with a mass concentration of paraffin wax of 20%. Add the magnesium powder into the coating solution at a ratio of 4:1, and disperse at...

Embodiment 2

[0052] The self-generating chemical temperature-raising agent for acidic heavy oil reservoirs in this embodiment includes a heat-generating agent and a triggering agent, and the heat-generating agent includes magnesium powder with a particle size not greater than 400 mesh and a coating layer for wrapping the magnesium powder , the triggering agent is a particle size not greater than 400 mesh P 2 o 5 powder, magnesium powder and P 2 o 5 The mass ratio of powder is 1:2.0, and described coating is paraffin coating or magnesium stearate coating;

[0053] When the coating layer is a paraffin wax coating layer, the preparation method of the heat generating agent comprises the following steps:

[0054] Step 1. Add paraffin to cyclohexane under stirring conditions at 70°C until completely melted to obtain a coating solution with a mass concentration of paraffin wax of 40%. Add the magnesium powder into the coating solution at a ratio of 6:1, and disperse at a constant temperature ...

Embodiment 3

[0067] The self-generating chemical temperature-raising agent for acidic heavy oil reservoirs in this embodiment includes a heat-generating agent and a triggering agent, and the heat-generating agent includes magnesium powder with a particle size not greater than 400 mesh and a coating layer for wrapping the magnesium powder , the triggering agent is a particle size not greater than 400 mesh P 2 o 5 powder, magnesium powder and P 2 o 5 The mass ratio of powder is 1:1.5, and described coating is paraffin coating or magnesium stearate coating;

[0068] When the coating layer is a paraffin wax coating layer, the preparation method of the heat generating agent comprises the following steps:

[0069] Step 1, under the stirring condition of 68 ℃, add paraffin in cyclohexane until completely melted, obtain the coating solution that the mass concentration of paraffin is 25%, then under the constant stirring condition of temperature, according to the quality of magnesium powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com