A converter dehydration device capable of improving flue gas dehydration effect

A dehydration device and converter technology, applied in the manufacture of converters, etc., can solve the problems of insufficient space and position, and achieve the effects of saving upper and lower space, saving electricity, gas recovery benefits, and good steam-water separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

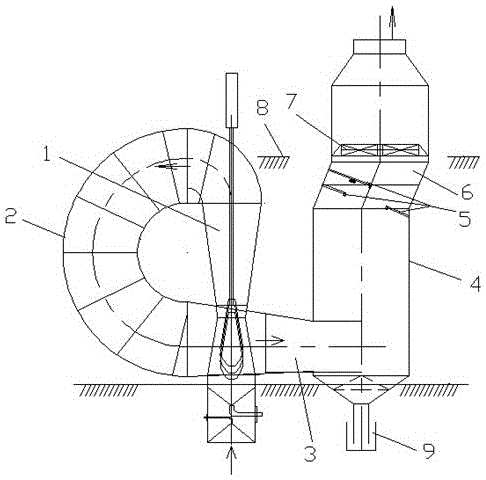

[0012] The invention breaks the traditional concept, and in order to overcome the problem of insufficient space, a swirl spray gun dehydrator is directly installed at the exit of the throat of the second-stage venturi tube to meet the dehydration effect of primary dust removal, realize the normal operation condition of the fan, and improve gas recovery power consumption and fan power saving effect.

[0013] The figure shows that when a normal dehydrator is installed, a vertically descending pipe greater than 4m is required at the outlet of the second-stage venturi tube 1, and then a vertically installed 15m dehydrator inlet is horizontally and tangentially connected, which requires 20m left and right and 25m up and down. space. In order to overcome the problem of insufficient installation space, the present invention designs a vortex steam-water separation pipeline 2 .

[0014] One end of the vortex steam-water separation pipe 2 is flange-connected to the throat of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com