Gas compressor with variable camber guide vanes

A technology of guide vanes and compressors, which is applied to components of pumping devices for elastic fluids, axial flow pumps, mechanical equipment, etc. and other problems, to achieve the effect of avoiding surge phenomenon, high work efficiency and large air intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is a compressor with variable curvature guide vanes.

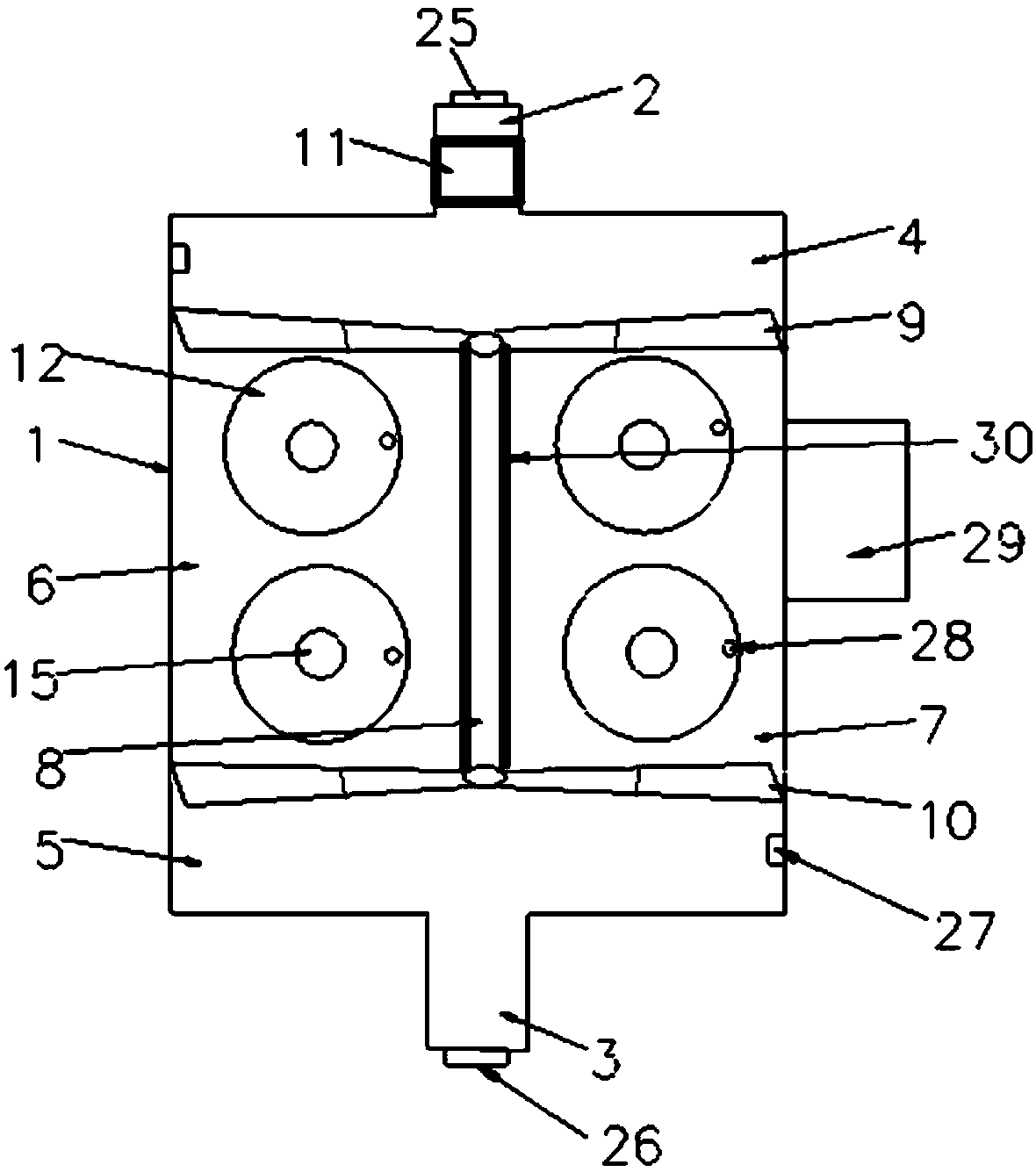

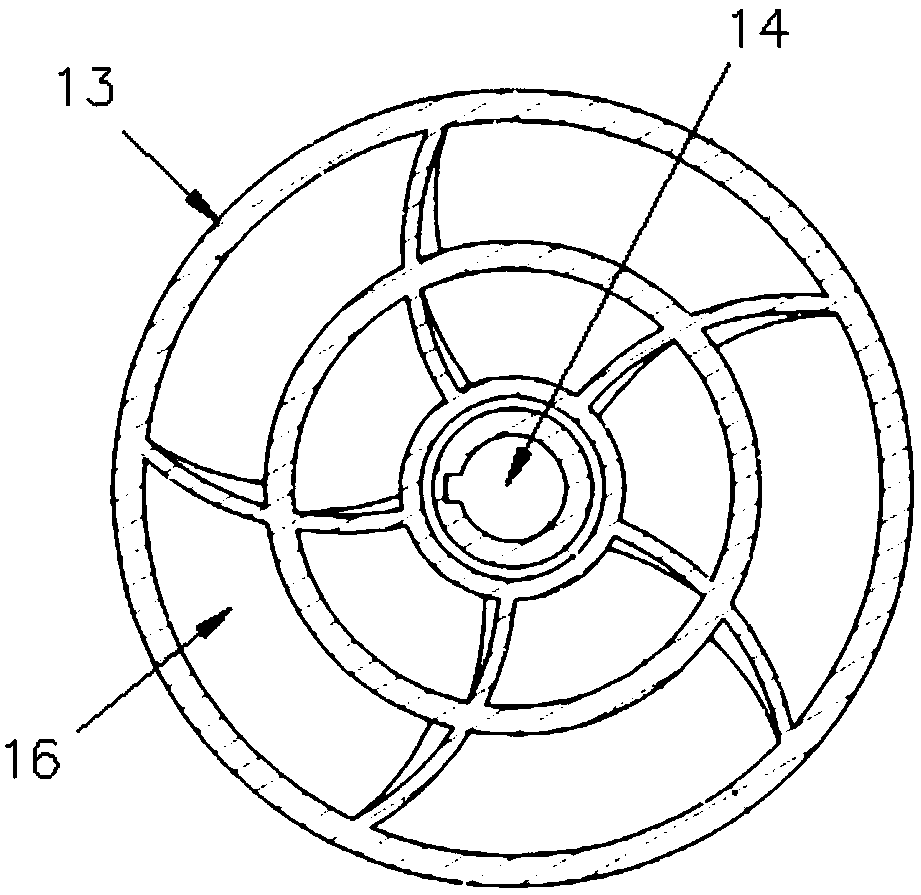

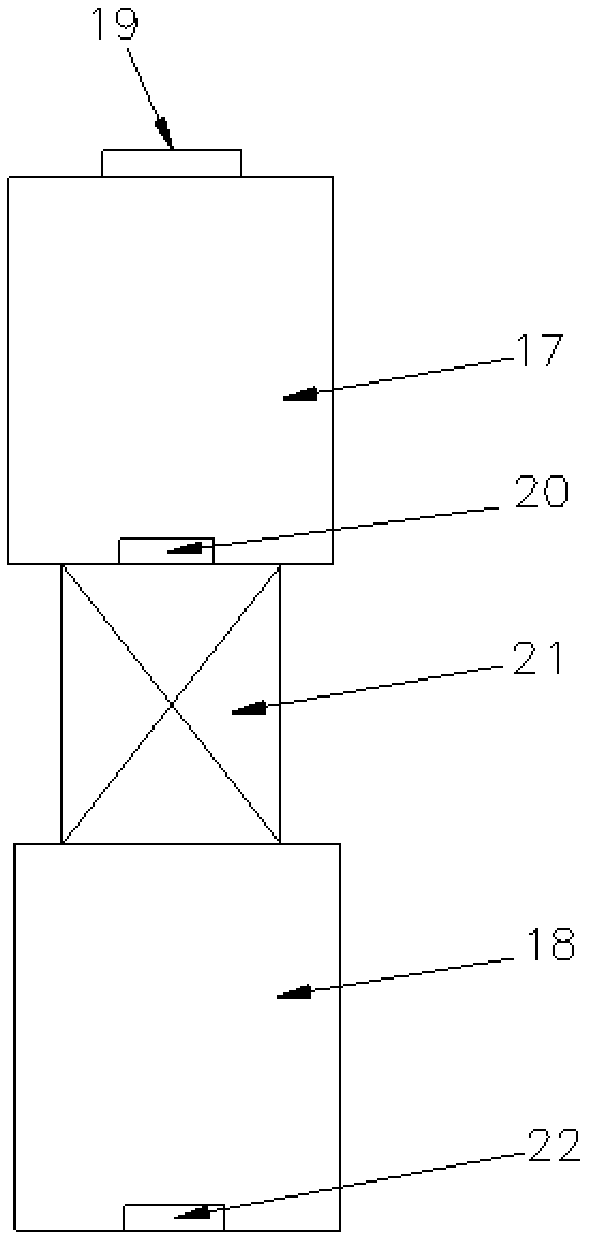

[0025] refer to Figure 1 ~ Figure 4 , the air compressor with variable curvature guide vanes in this embodiment is composed of a body assembly, a supercharging device and a servo motor; wherein, the body assembly includes a casing 1, a main air chamber 4, an auxiliary air chamber 5, a first impeller Bin 6, second impeller bin 7, partition 8, first variable curvature guide vane 9, second variable curvature guide vane 10, impeller assembly 12, booster pump 21, fixed vane 23, hinged vane 24, air intake One-way valve 25, air outlet one-way valve 26, air pressure sensor 27, speed sensor 28, controller 29 and soundproof cotton 30; the top and bottom of housing 1 are provided with air inlet 2 and air outlet 3 respectively; the inner chamber of housing 1 The chamber is provided with a main air chamber 4 , an auxiliary air chamber 5 , a first impeller chamber 6 and a second impeller chamber 7 , the main air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com