Circular weaving machine jacquard mechanism comprising air cylinders for lifting heald rods

A circular loom and heald bar lifting technology, which is applied to the opening device of the circular loom and the jacquard mechanism of the circular loom, can solve the problems of difficulty in cam manufacturing, only single-layer fabric can be weaved, and the number of shuttles cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

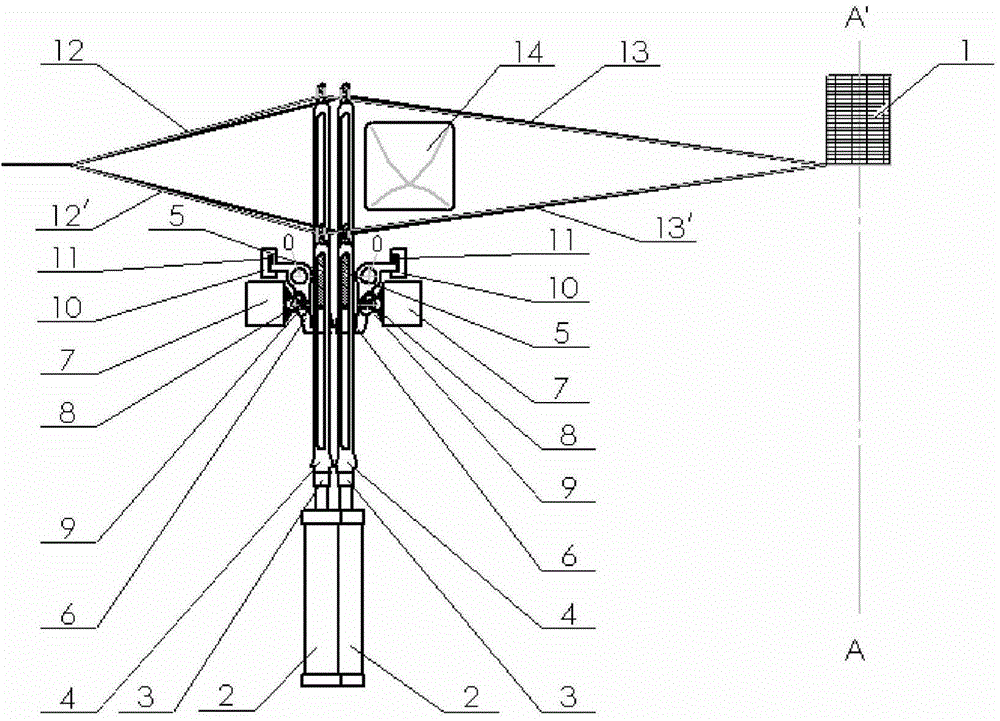

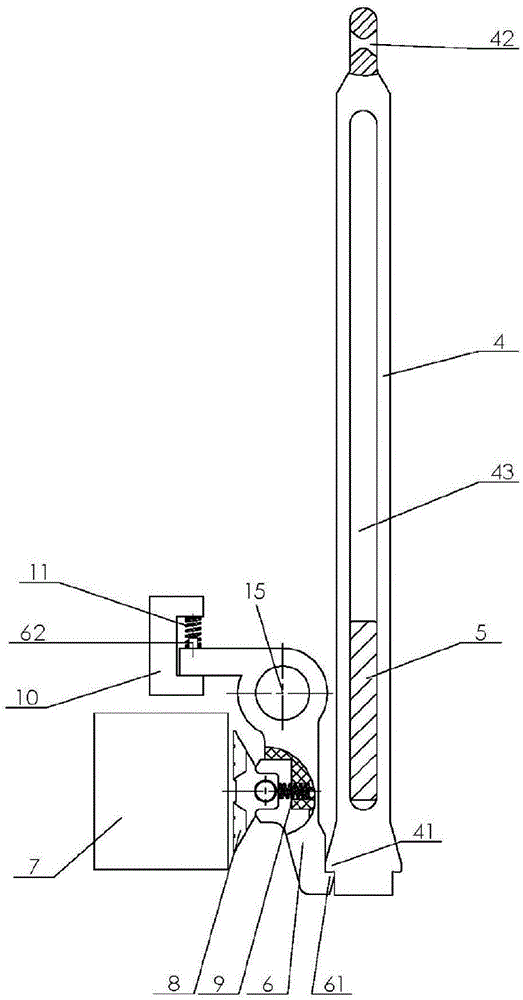

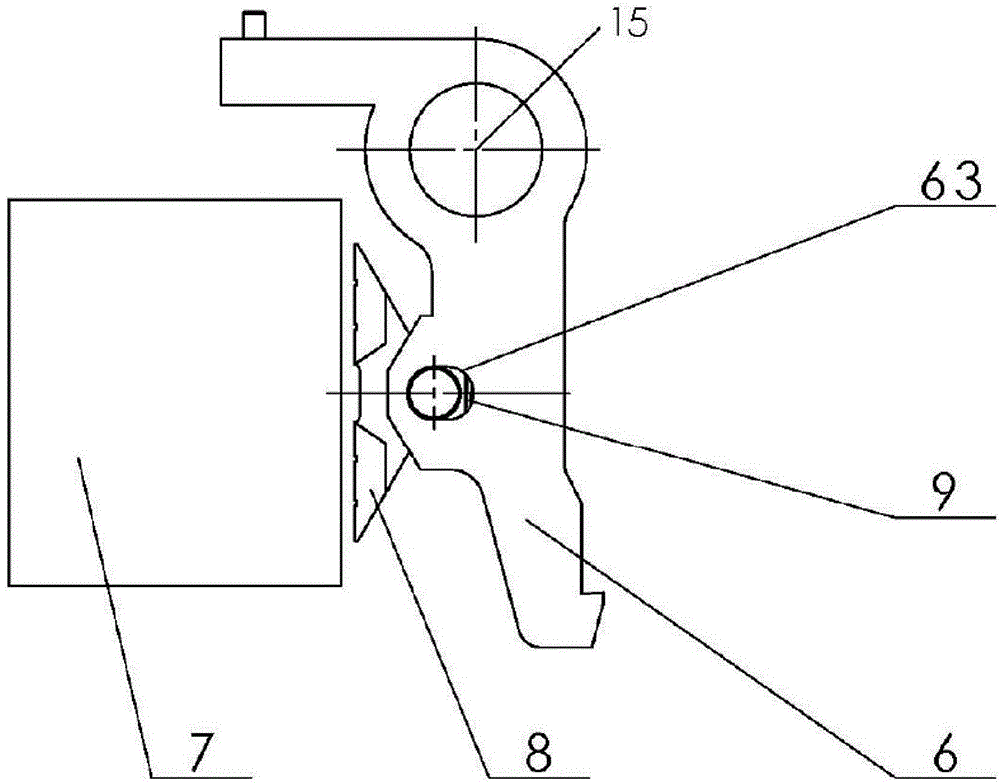

[0019] Such as figure 1 , figure 2 and image 3 As shown, a circular loom jacquard mechanism for a cylinder lifting heald rod of the present invention includes a circular frame (not shown in the figure) of the circular loom, and an inner layer jacquard device and an outer jacquard device are arranged in the circular frame. The layer jacquard device, the inner layer jacquard device and the outer layer jacquard device respectively include a plurality of jacquard units, the jacquard units in the inner layer jacquard device are evenly arranged along a first circle, and the jacquard units in the outer layer jacquard device are arranged along a second circle. The circles are evenly arranged, the first circle and the second circle are coaxial with the circular frame, and any jacquard unit includes cylinder 2, heald lifting rod 3, heald rod 4, guide rod 5, swing rod 6, electromagnetic Iron 7 and armature 8, cylinder block of cylinder 2, guide rod 5 and electromagnet 7 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com