Diaphragm type angular travel pneumatic actuating mechanism

A technology of pneumatic actuators and angular strokes, which is applied in the direction of engine components, mechanical equipment, valve details, etc., can solve the problems of difficult fitting between pneumatic actuators and valves, poor control accuracy, and low degree of cooperation, so as to improve rigidity, Guarantee the anti-seismic strength of the connection and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

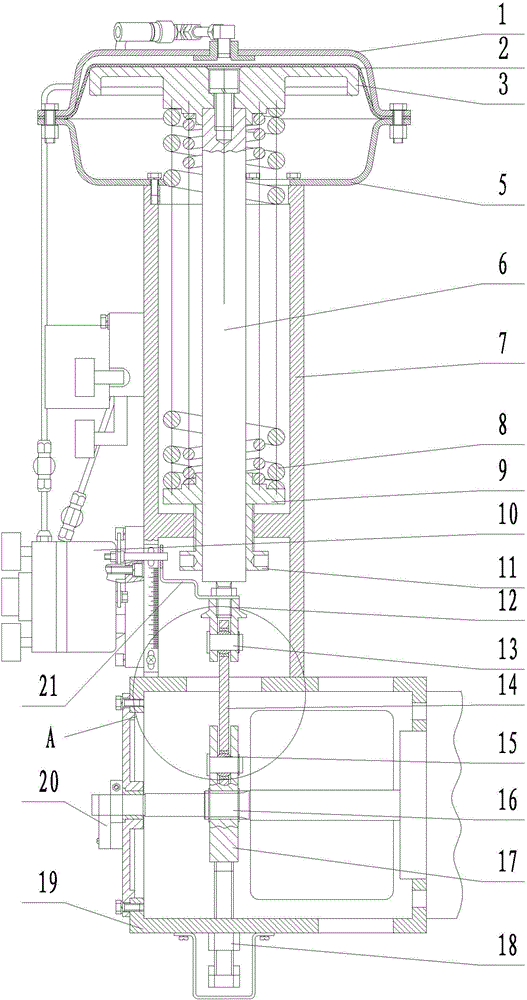

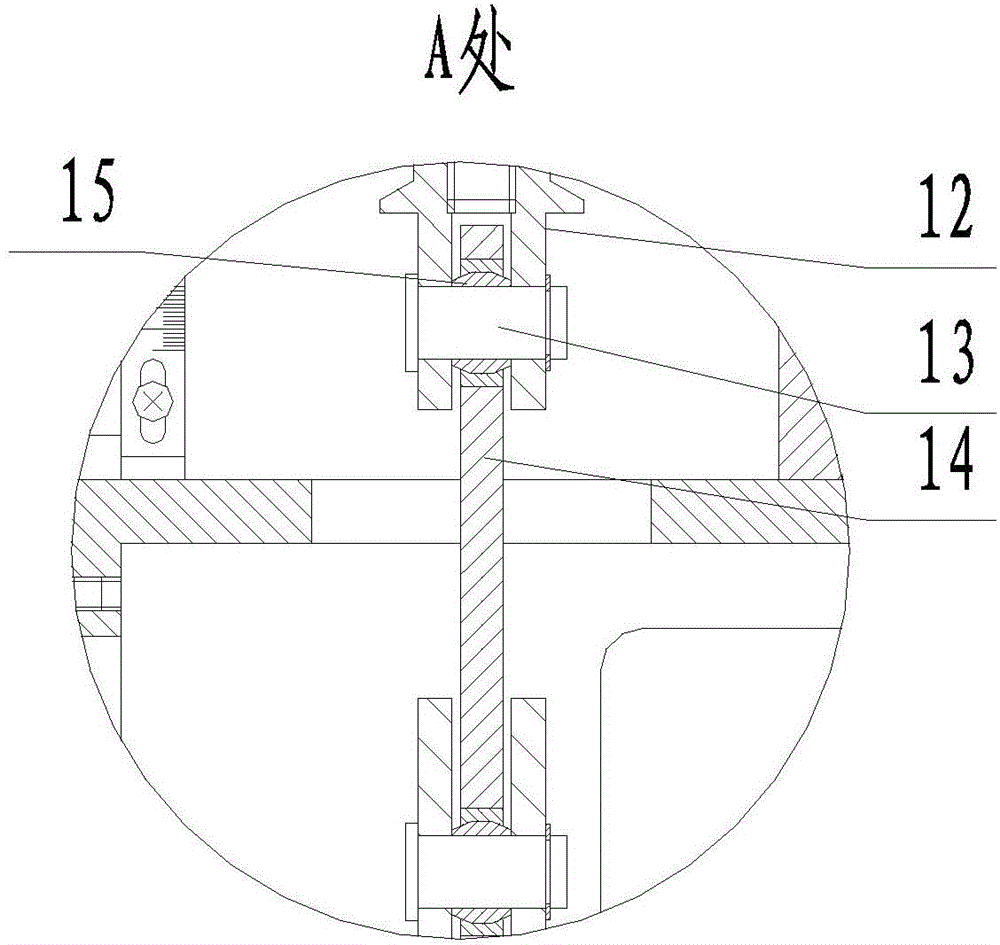

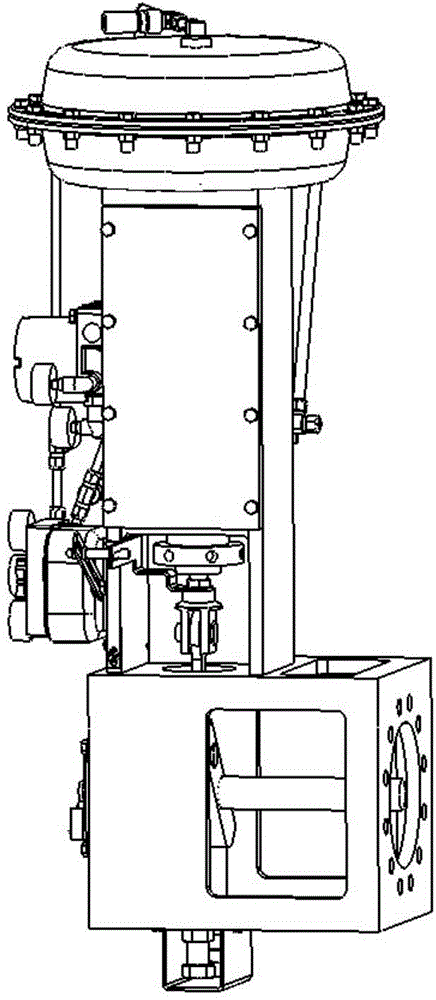

[0030] The invention as Figure 1-5 As shown, the valve stem 16 is used to drive the valve. The pneumatic actuator includes an upper housing 1, a lower housing 5, a push rod driving mechanism, a push rod 6, an upper frame 7, a lower frame 19, a linkage mechanism, and a feedback mechanism and limit position trigger mechanism;

[0031] The upper casing 1, the lower casing 5, the upper frame 7, and the lower frame 19 are fixedly connected sequentially from top to bottom, and the upper frame 7 includes an upper cavity and a lower cavity connected as one, and the upper cavity and the lower cavity There is a partition between them, and a threaded hole is opened in the middle of the partition;

[0032] The push rod 6 is arranged vertically and reciprocates up and down under the drive of the push rod driving mechanism. The upper end of the push rod 6 extends between the upper casing 1 and the lower casing 5, and the push rod 6 The lower end of the threaded hole extends out to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com