Method and device for capturing bubble polymerization process

A technology of bubble and generating device, which is applied in the field of measuring the dynamic behavior of bubbles in hydrodynamics multiphase flow, can solve the problems such as the inability to accurately capture the dynamic polymerization process of bubbles, and achieve the effects of prolonging the observation and recording time, low energy consumption, and not easy to rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

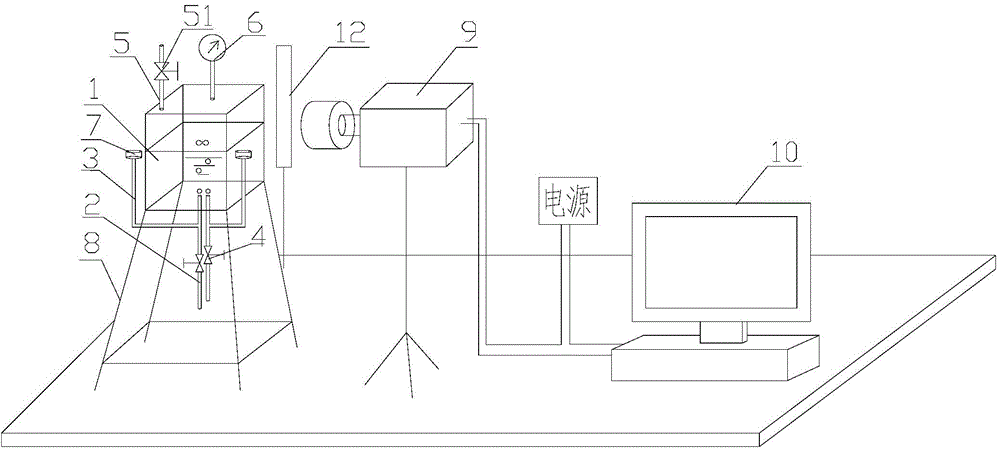

[0029] like figure 1 As shown, a device for capturing the method of the bubble polymerization process includes a bubble polymerization generating device and a shooting and data processing device for recording and analyzing the bubble movement process in the bubble polymerization generating device; the shooting and data processing device includes a high-speed camera 9, A computer 10 and an auxiliary light source 12 . During work, the bubble polymerization generating device is fixed on the bracket 8, and the high-speed camera 9 is connected to the computer 10 through transmission. When shooting, turn on the auxiliary light source 12 to illuminate the dynamic bubble polymerization process in the bubble polymerization generating device, record it by the high-speed camera 9, and transmit the data to the computer 10 at the same time for further analysis.

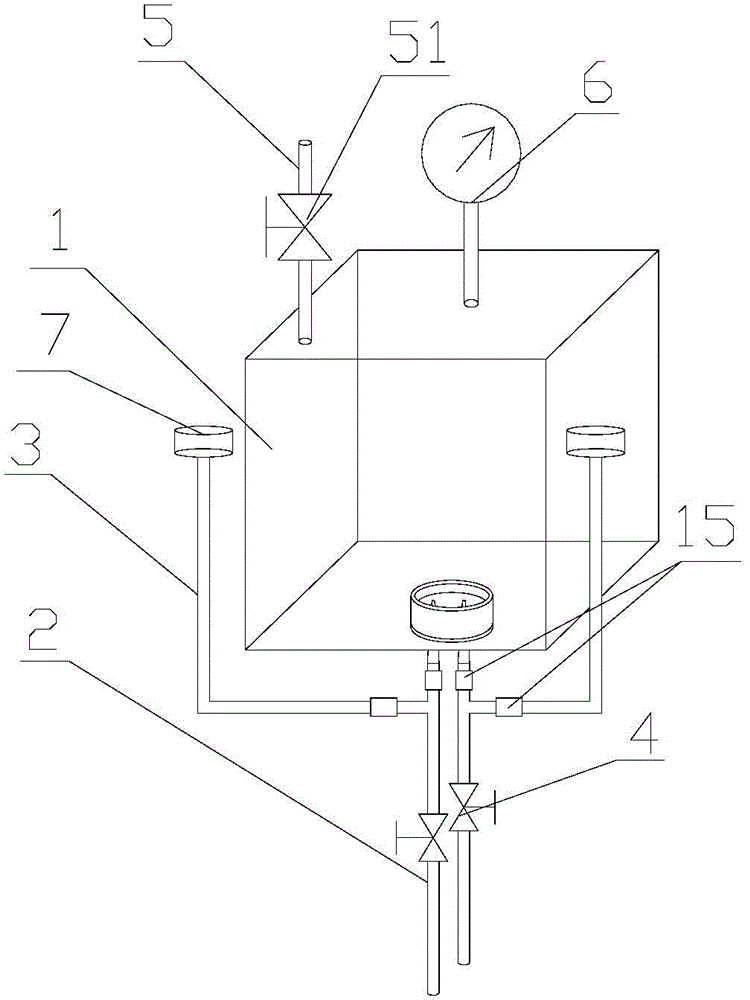

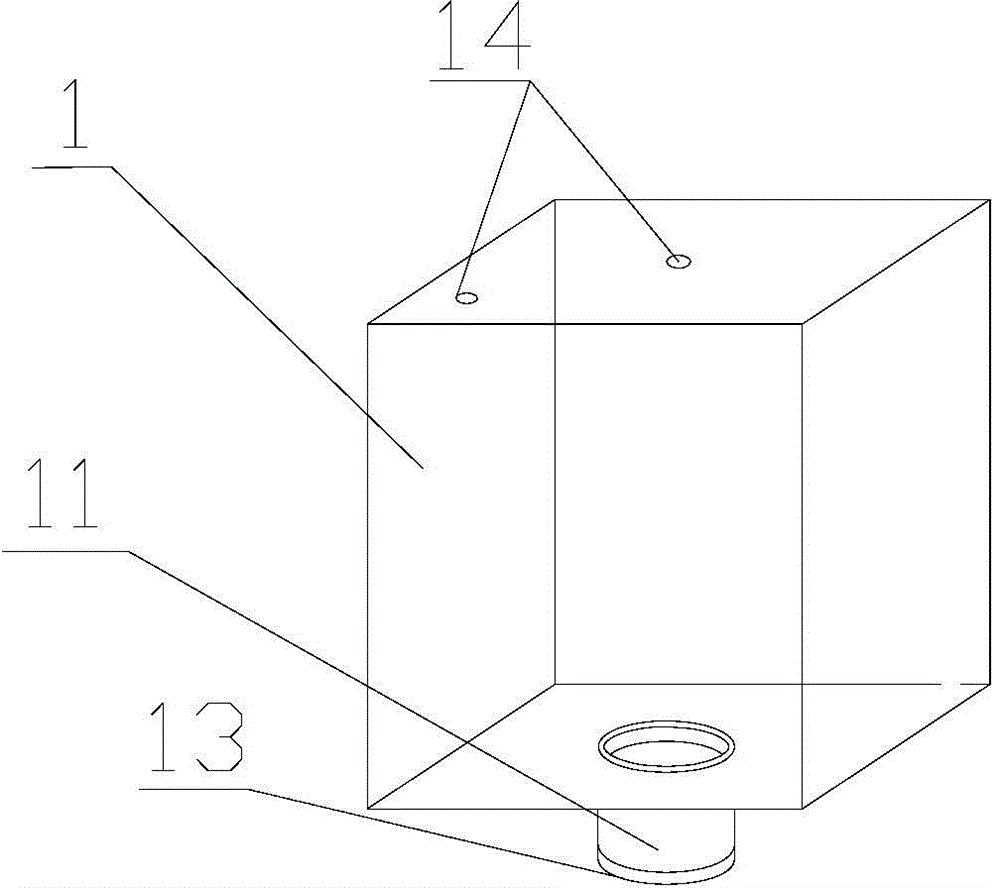

[0030] like figure 2 As shown, the bubble polymerization generating device includes a sealed liquid-filled container 1, a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com