Novel vehicle door hinge and stopper integrated test bench rack

A door hinge and comprehensive testing technology, which is applied in vehicle testing, machine/structural component testing, mechanical component testing, etc. It can solve unfavorable test system upgrades and extended tests, failure to output torque/angle curves, and impact collection Data accuracy and other issues, to achieve the effect of upgrading and expanding, supplementing test capabilities and test scope, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

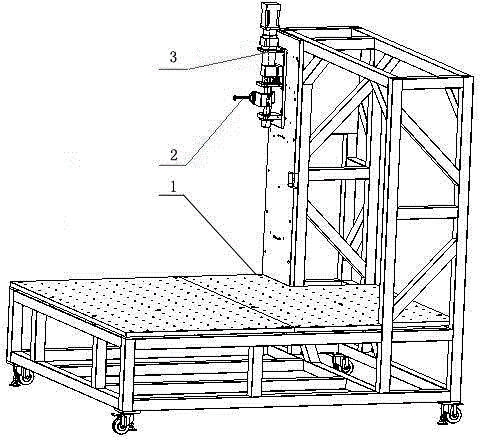

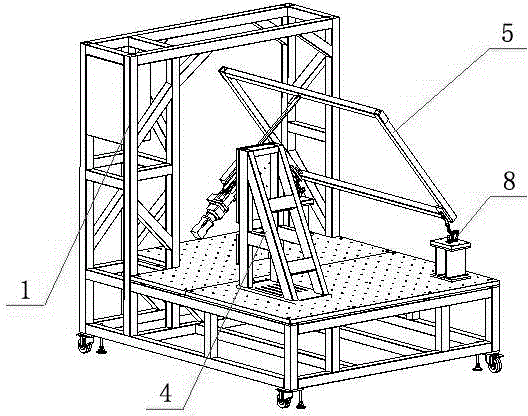

[0032] Embodiment two, such as figure 2 As shown, the combination of rigid platform 1, displacement / force detection module 4 and simulated rigid engine cover 5 can detect the lateral stiffness and over-opening stiffness of the engine cover hinge; The loading rod 405 applies a load to the rigid frame 502, and the real-time data measured by the displacement sensor 404 and the force sensor 403 are sent to the microcomputer for analysis, and a report is generated to complete the test process.

Embodiment 3

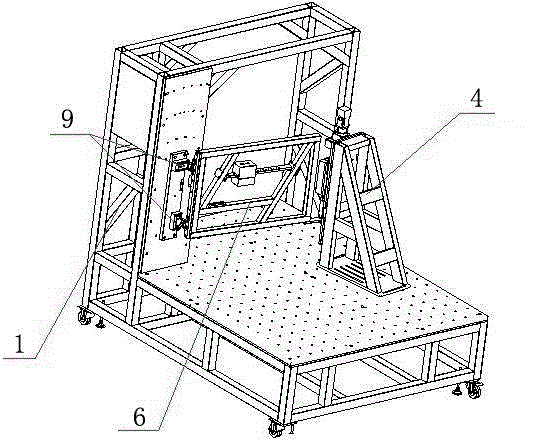

[0033] Embodiment three, such as image 3 As shown, the combination of rigid bench 1, displacement / force test module 4 and simulated rigid side door 6 can detect the sagging stiffness of the side door hinge and the over-opening strength of the door stopper; the servo motor B401 in the displacement / force detection module 4 passes through the transmission part 402 The loading rod 405 applies a load to the force-receiving block 605 of the frame 603, and the real-time data measured by the displacement sensor 404, the force sensor 403, and the sensor 604 are sent to the microcomputer for analysis, and a report is generated to complete the test process.

Embodiment 4

[0034] Embodiment four, such as Figure 4 As shown, the combination of the rigid platform 1, the simulated rigid side door 6 and the impact velocity module 7 can detect the impact resistance strength of the door stopper; the drive cylinder 702 of the impact velocity detection module 7 applies a force to the frame 603 of the simulated rigid side door 6 through the drive rod 701. For load, the real-time data measured by the sensor 604 is sent to the microcomputer for analysis, and a report is generated to complete the test process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com