Particle size analyzer

A particle size analyzer and particle technology, applied in the field of particle size analyzer, can solve the problem that the measurement range cannot cover the requirements of particle measurement, and achieve the effect of being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

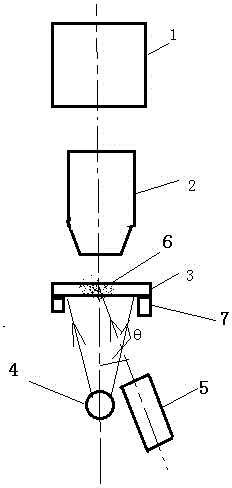

Embodiment 1

[0042] Embodiment 1: A particle size measuring device combining image method and dynamic light scattering, characterized in that the measuring device adopts an area array image sensor 1 as a measuring element, and a microscope objective lens is arranged under the area array image sensor 1 2. A sample cell 3 is placed on the focal plane of the microscope objective lens 2, and two light sources are placed under the sample cell 3, one of which is a transmission light source 4 using a light-emitting diode LED or a miniature bulb, and the transmission light source 4 is arranged In the axial direction of the sample cell 3 and the microscope objective lens 2, another scattered light source 5 using a laser is incident on the sample cell 3 at an angle of θ of 5-90 degrees; when measuring particles above microns, it is located in the sample cell 3 The transmitted light source 4 below emits illumination light to illuminate the measured particle sample 6 in the sample cell 3, the particle ...

Embodiment 2

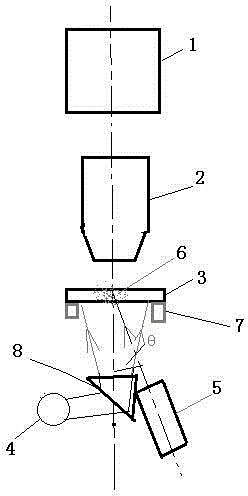

[0047] When considering the structural needs, the transmitted light source 4 is arranged at an angle with the optical axis of the sample cell 3 and the microscope objective lens 2.

[0048] At an angle of 90 degrees, the optical axis of the microscopic objective lens 2 and the light rays emitted by the transmission light source 4 are vertically intersected with a total reflection prism or reflector 8. The light is deflected by 90 degrees through the total reflection prism or mirror 8 to illuminate the particle sample on the sample cell. The particle image is enlarged and imaged on the image plane by the microscope objective lens 2, and the image signal obtained after the enlarged image is received by the image sensor 1 is sent to a computer for image processing to obtain the particle size distribution.

[0049] The sample pool 3 in the embodiment can be a cuvette or slide. The area array image sensor 1 in the embodiment can adopt CCD or CMOS device. The laser used for the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com