Fixing device and jig for screen testing

A technology for fixing devices and test fixtures, applied in the directions of measuring devices, measuring device casings, components of electrical measuring instruments, etc., can solve the problems of increased production costs, bumps and damages, increased production losses, etc., to reduce The effect of production footprint, reduced friction and collisions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

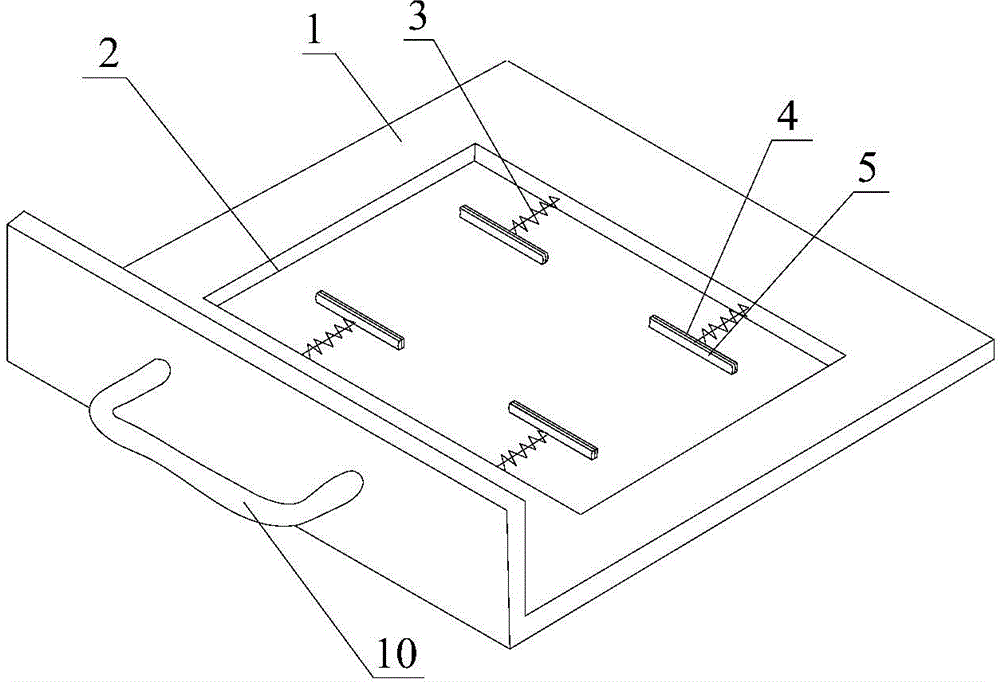

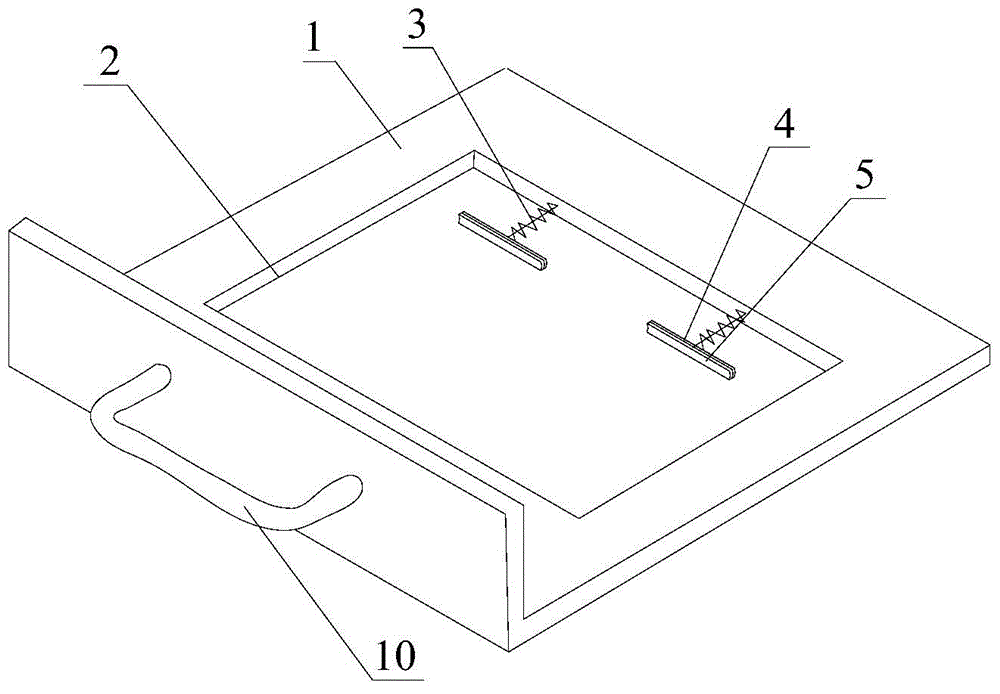

[0027] Such as figure 2 As shown, a fixing device for screen testing includes a product fixing part and a drawing part connected with the product fixing part, the product fixing part is used to fix the screen to be tested, and the drawing part is fixed on the product One side of the mount for easy pulling out or pushing in of the product mount.

[0028] The product fixing part includes a product fixing plate 1, which is provided with at least one fixing groove 2 for placing the screen to be tested on the product fixing plate 1, and the fixing groove 2 is used to accommodate the screen to be tested, because the electronic product The screen has multiple specifications. If one screen fixing device corresponds to the specification of an electronic product, multiple fixing devices need to be prepared. Production and management are both troublesome problems, and the production cost is also increased. Therefore, the present invention At least one elastic clamping member for clampi...

Embodiment 2

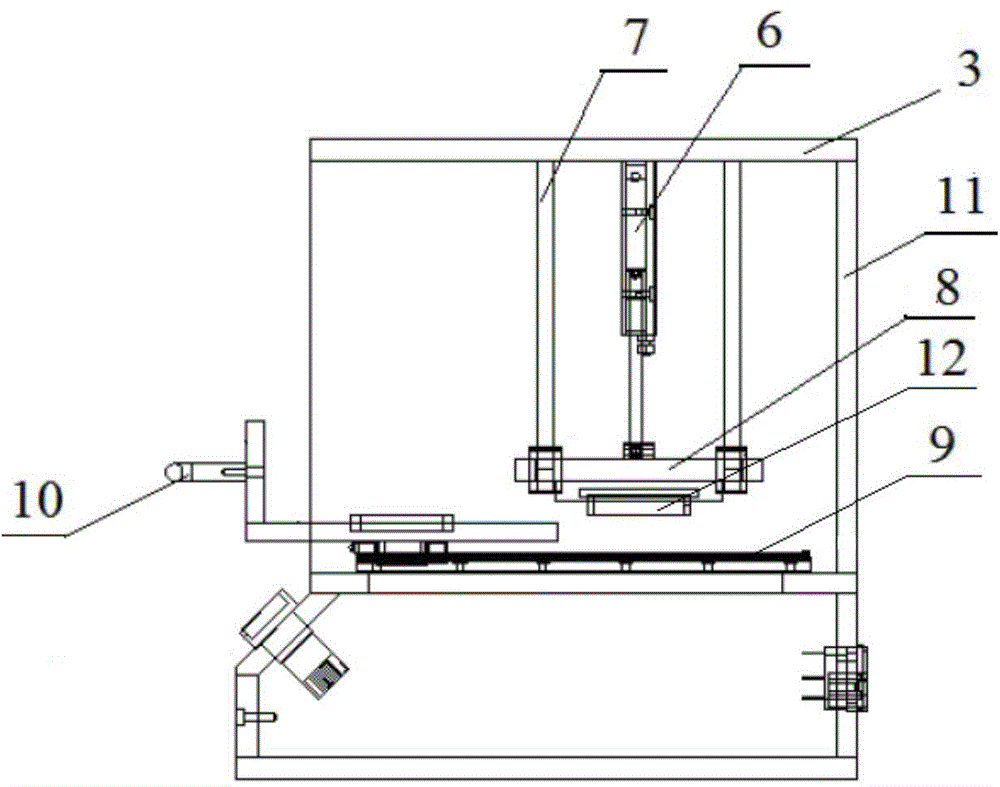

[0036] A screen test fixture comprises a test frame and a test assembly installed in the test frame, the test assembly includes a descending cylinder and a guide track fixed on the top of the test frame, the free end of the descending cylinder is fixed with a lower plate, The two ends of the lower platen are respectively provided with guide ends, and the guide ends are arranged in the guide track, and the test frame also includes a fixing device for the screen test fixture.

[0037] The fixture for screen testing includes a product fixture and a drawer connected to the product fixture, the product fixture is used to fix the screen to be tested, and the drawer is fixed on one of the product fixtures side for easy pull-out or push-in product holders.

[0038] The product fixture includes a product fixing plate, and the product fixing plate is provided with a fixing groove 2 for placing the screen to be tested, and the fixing groove 2 is used to accommodate the screen to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com