OLED linear array laser packaging device

A laser packaging and line array technology, applied in the field of OLED display, can solve the problems of low operating efficiency and difficulty in guaranteeing the accuracy of laser packaging, and achieve the effects of improving efficiency, stable device performance, and meeting large-area packaging and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

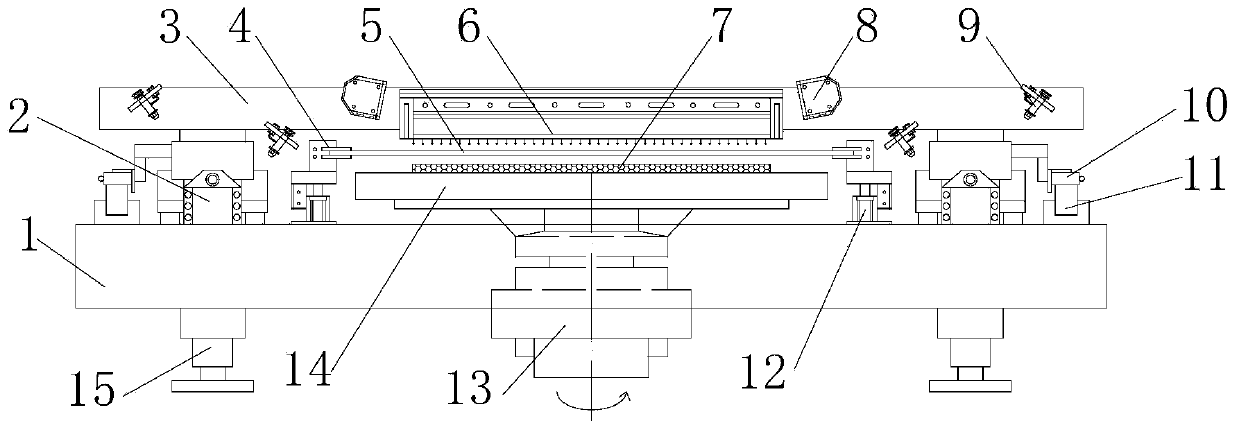

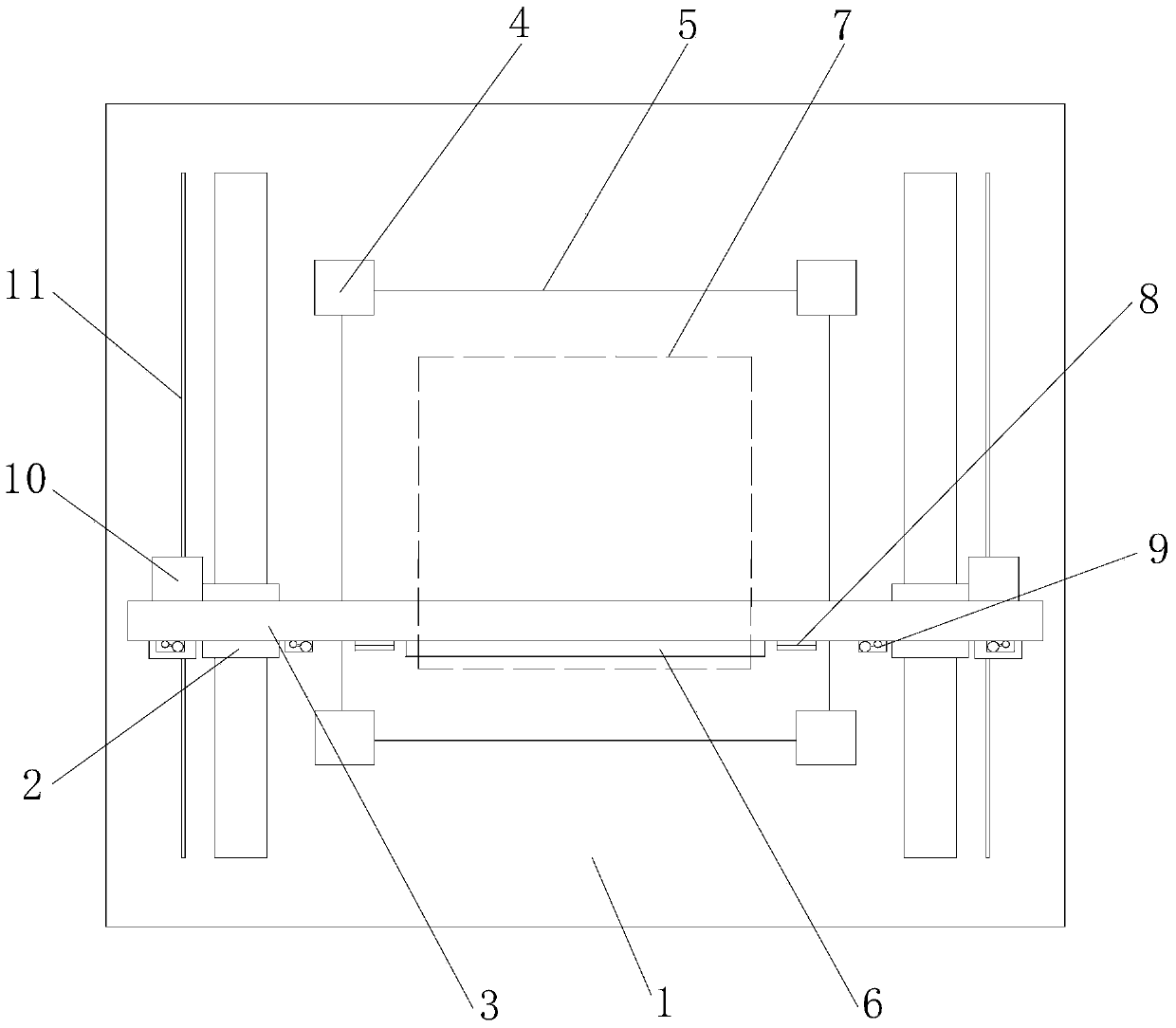

[0017] like figure 1 and figure 2 As shown, the present invention discloses that the technical solution of the present invention is: an OLED linear array laser packaging device, including a manipulator and a base 1, and two integrated stepping motor guide rails are symmetrically installed on the left and right sides of the upper surface of the base 1 2. A truss 3 is installed between the two integrated stepping motor guide rails. A linear array laser source 6 is installed in the middle of the truss 3. A round hole is arranged in the center of the base 1. A servo rotating motor 13 is installed in the lower part of the round hole. Servo rotation The upper part of the motor 13 is connected with an adsorption platform 14, and the outer four corners of the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com