Strip cathode wire for electrostatic dust collector

A technology of electrostatic precipitator and strip cathode, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of low current density, unsatisfactory effect of dust removal and fog removal, corona dead zone, etc., and achieve high discharge current and simple structure , The effect of low corona onset voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

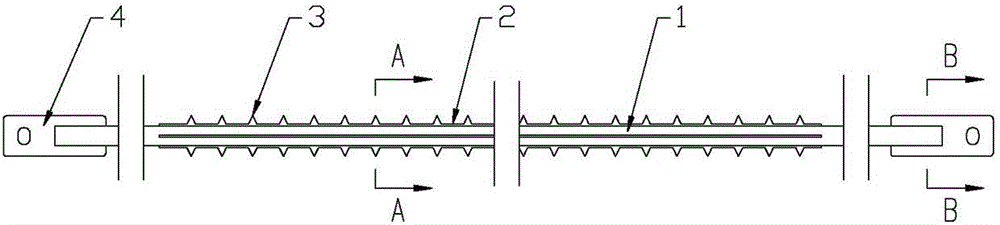

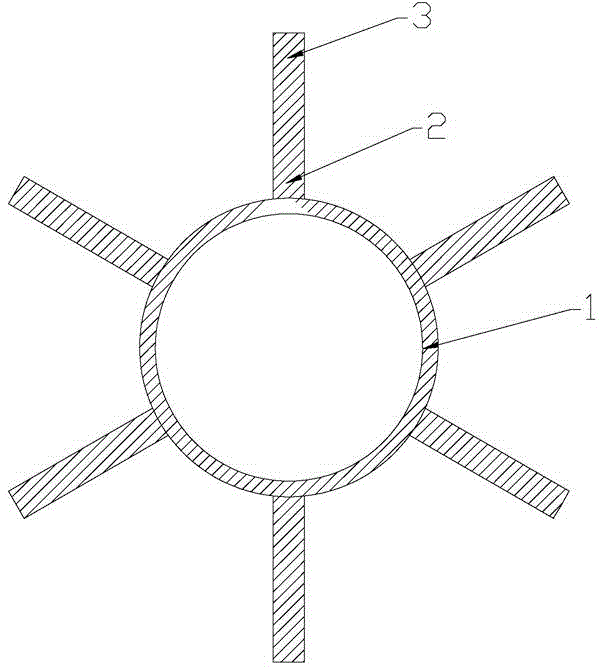

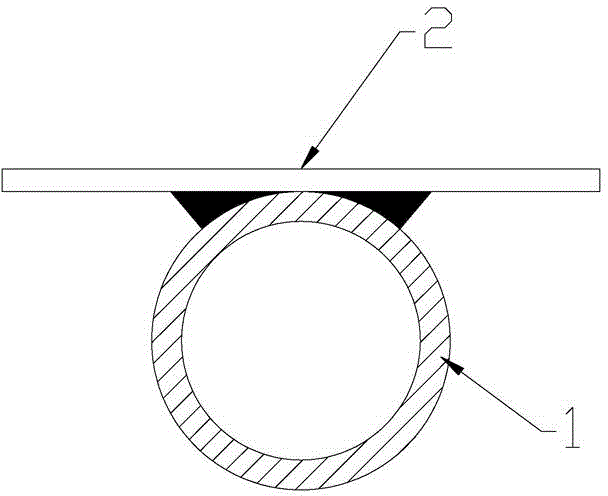

[0023] Such as Figure 1-3 Shown: a strip-shaped cathode wire for an electrostatic precipitator, including a cathode rod 1 with an outer diameter of 10-50mm. Rack 2, the discharge rack 2 is arranged along the length direction of the cathode rod 1 and the discharge rack 2 is evenly arranged along the circumference of the cathode rod 1, and one cathode rod 1 is provided with three or more discharge racks 2 and the discharge racks The strip 2 is provided with pointed discharge tips 3 arranged at intervals, figure 2 Shown is that a cathode rod 1 is provided with the cathode wire of six discharge racks 2 and the cathode rod 1 is a rigid tube; for the structure of the discharge rack 2 and the discharge tip 3 on it, the discharge tip 3 The ratio of the height of the cathode rod 1 to the radius of the outer circle of the cathode rod 1 is 1:0.8 to 3 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com