A large-volume honeycomb corona plasma 3D uniformity adjustment device

A plasma and regulating device technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of electric field distortion and high spark breakdown voltage, and achieve low corona voltage, high spark breakdown voltage, and good discharge stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

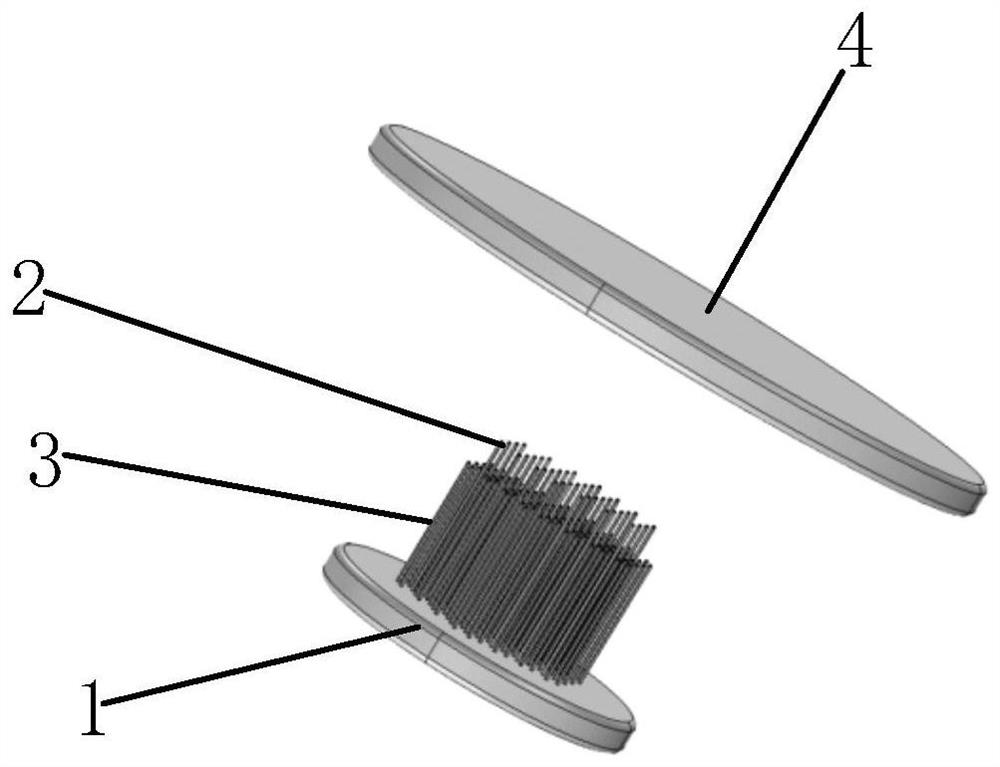

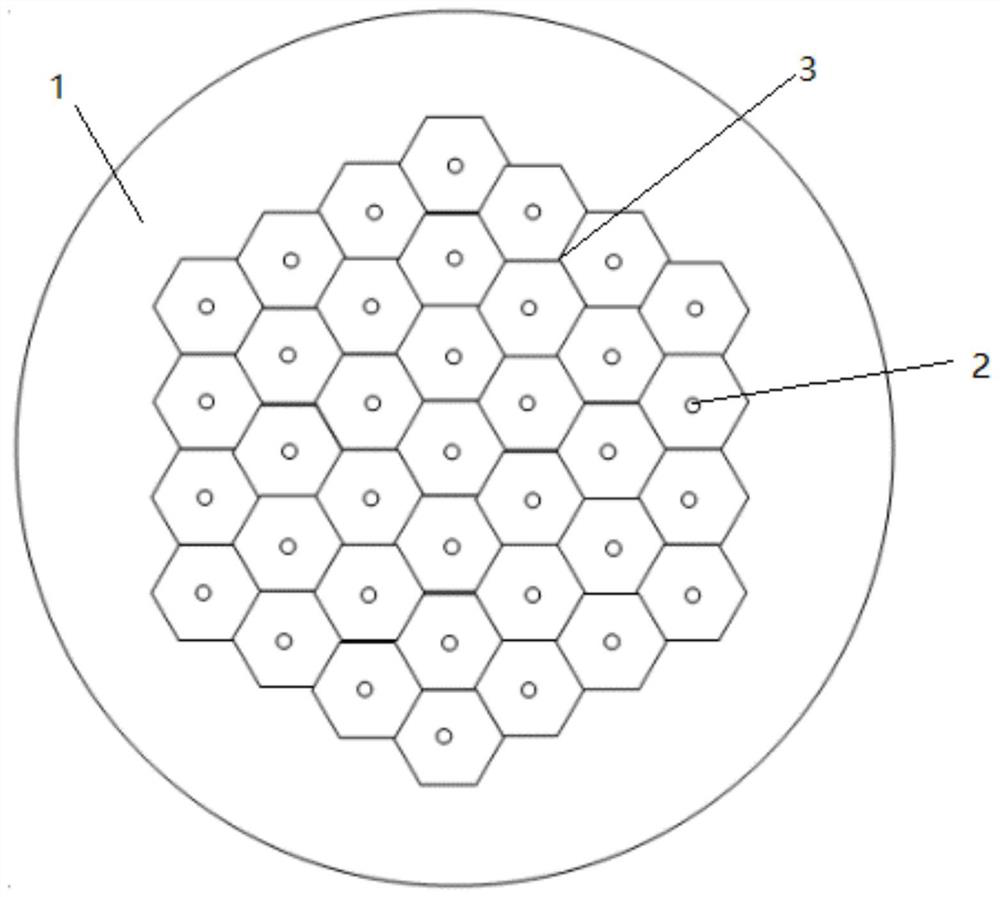

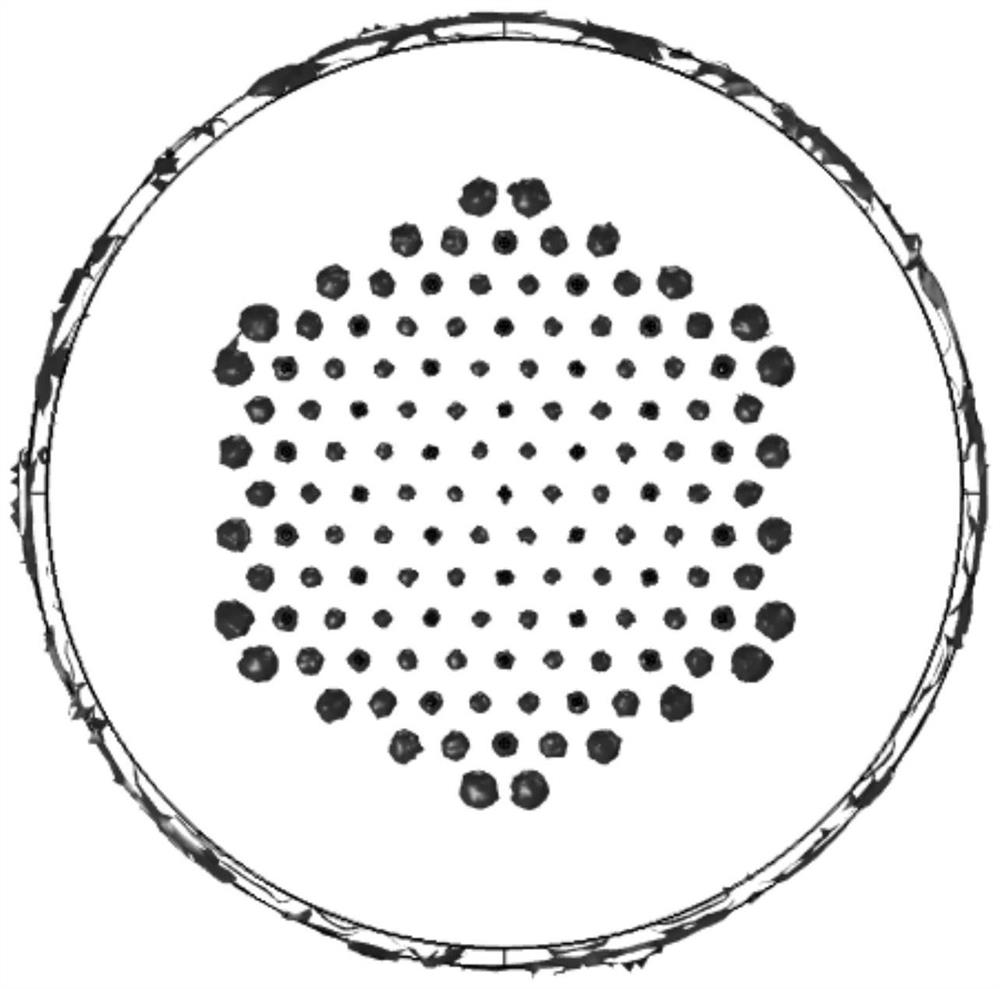

[0031] Such as figure 1 As shown, a large-volume honeycomb corona plasma 3D uniformity adjustment device includes a first flat structure 1, an adjustable length adjustment needle 2 is arranged on the end surface of the first flat structure 1, and the adjustment needle 2 is perpendicular to The first plate structure 1, the number of the adjustment needles 2 is several, and the electrode needles 3 are arranged around each adjustment needle 2, the number of the electrode needles 3 is six, and the distance between the six electrode needles 3 and the adjustment needles 2 is equal , the electrode needles 3 are perpendicular to the first plate structure 1, the six electrode needles 3 form a honeycomb unit, and each two adjacent adjustment needles 2 share two of the six electrode needles 3, and all the electrode needles 3 form The honeycomb multi-needle electrode, the first flat plate structure 1, the honeycomb multi-needle electrode and the regulating needle 2 form a combined dischar...

Embodiment 2

[0034] This embodiment is carried out on the basis of Embodiment 1. The present invention mainly consists of a honeycomb multi-needle electrode composed of electrode needles 3, an adjustable effective length regulating needle 2 in the center of the honeycomb unit, and a first flat structure 1.

[0035] Among them, the honeycomb multi-needle electrode structure is composed of corona needles, such as figure 2 shown. Among them, the material of the corona needle is tungsten, which mainly takes advantage of the high melting point and stable chemical properties of the metal tungsten material to ensure that the corona needle can be used repeatedly. The base material is aluminum, which plays the role of support and electrical connection.

[0036] The function of the adjusting needle 2 with adjustable effective length in the center of the honeycomb unit mainly depends on the retractable fixing hole on the first flat structure 1 to adjust the length of the adjusting needle 2 protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com