Online roll changing device

A technology of roll changing device and push-pull device, which is applied in the direction of metal rolling, metal rolling racks, manufacturing tools, etc., which can solve the problems of damaging online steel strips, affecting production efficiency, and surface damage, and achieves a reduction in floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

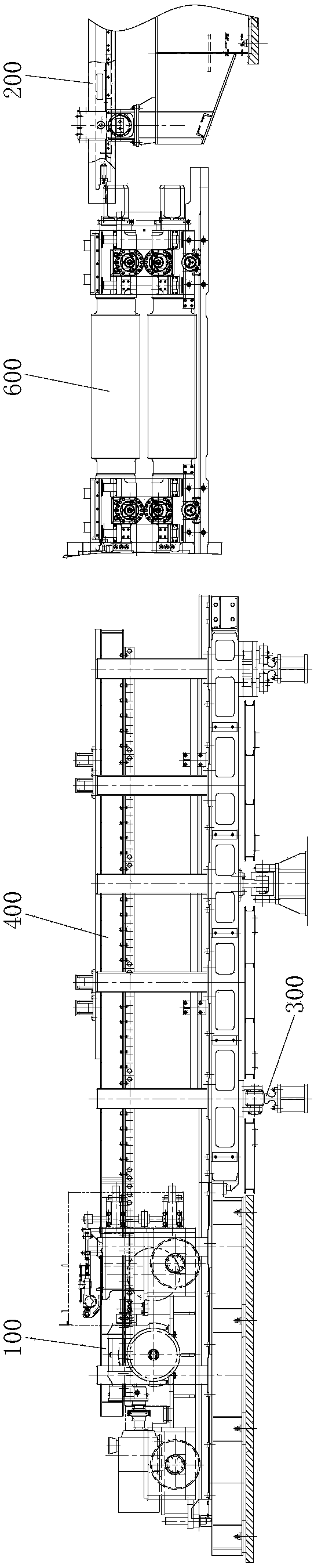

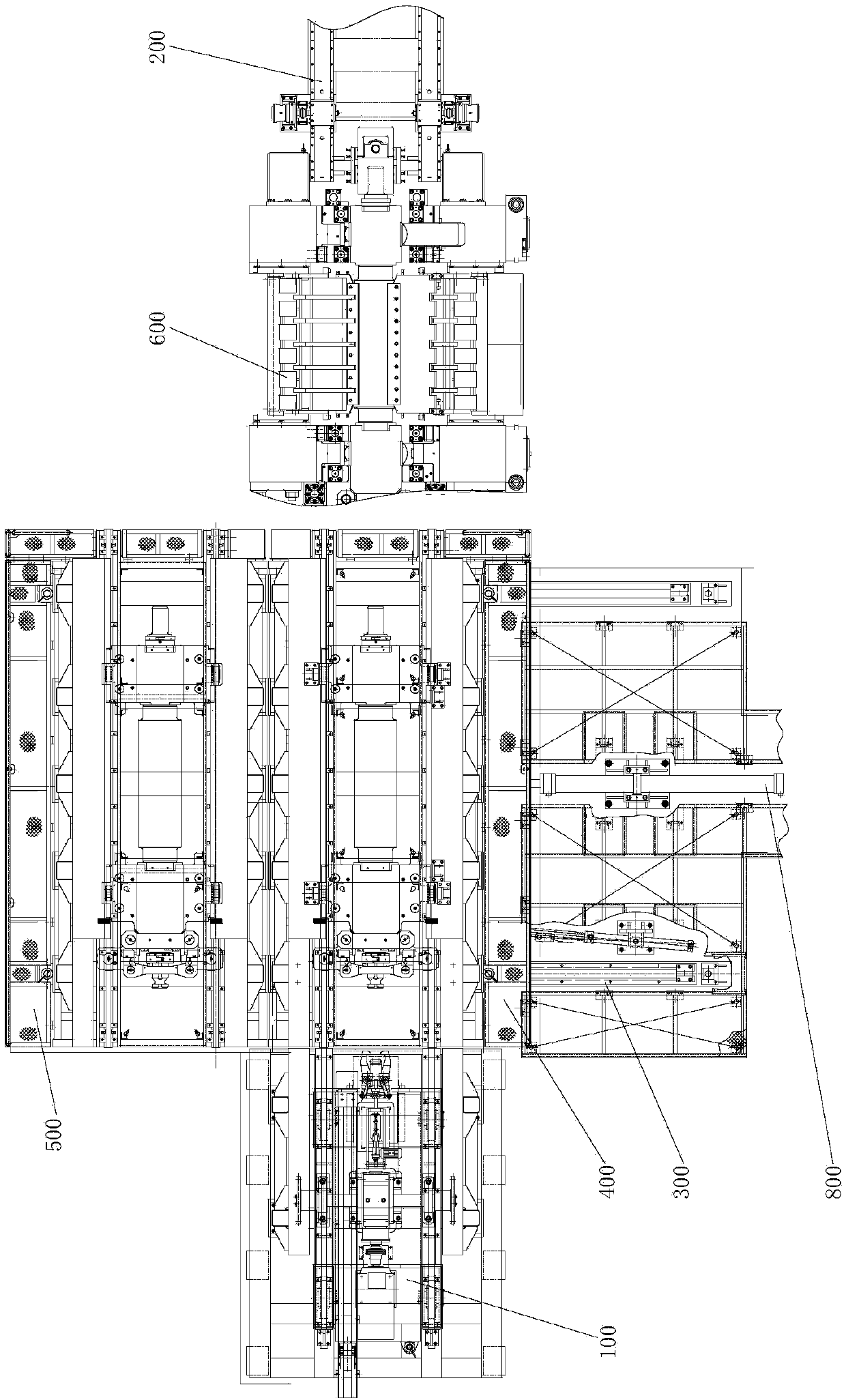

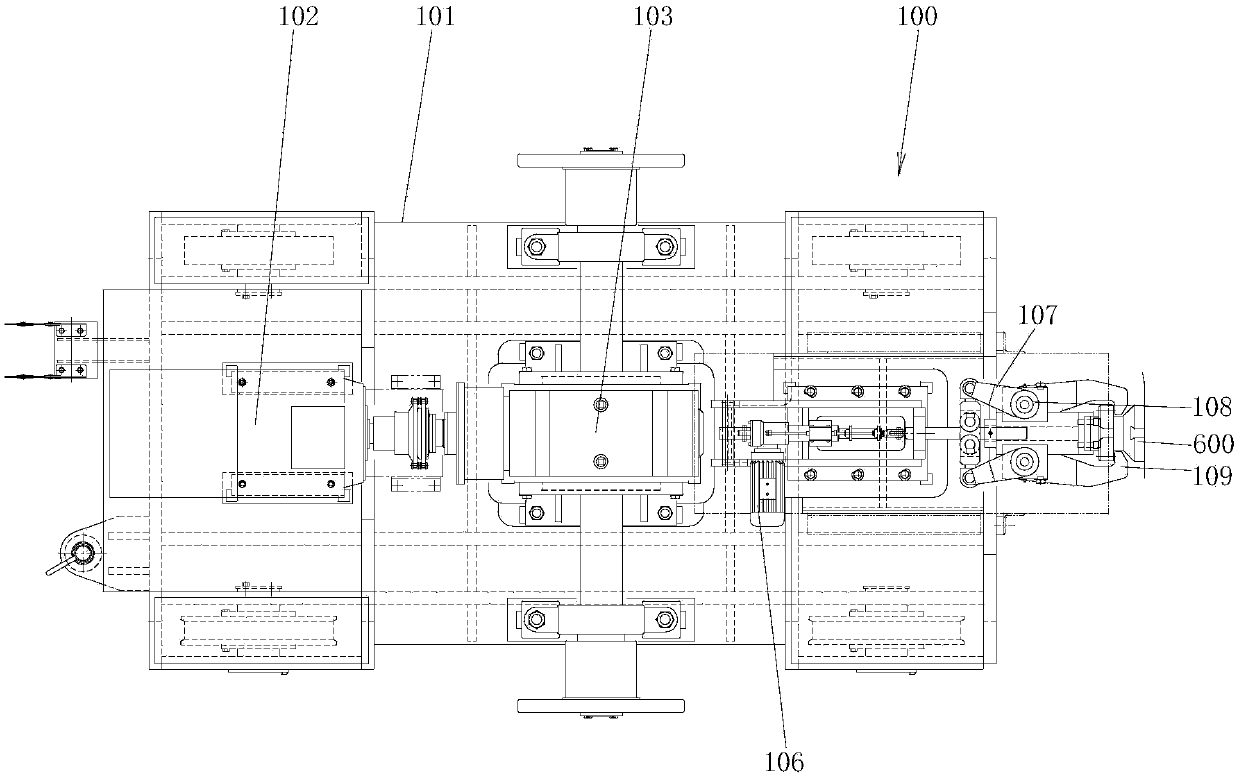

[0042] refer to figure 1 and figure 2 , the online roll changing device of the present invention includes: a push-pull device 100 that automatically pulls out old work rolls on the rolling mill and feeds new work rolls into the rolling mill. And the track moving device 200 inserted into the rolling mill to unlock the old rolls and support the old work rolls and new work rolls during the roll change process. The track device 300 arranged between the push-pull device and the track moving device, the axial direction of the track device and the push-pull device are perpendicular to each other. The first moving mechanism 400 carrying old work rolls and the second moving mechanism 500 carrying new work rolls are fitted on the track device. That is to say, the present invention is composed of push-pull device 100, track moving device 200, track device 300, first moving mechanism 400, and second moving mechanism 500. Each part and the relationship between each part are described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com