Horizontal continuous casting crystallizer

A technology of horizontal continuous casting and crystallizer, applied in the field of horizontal continuous casting device, can solve the problems of complex structure and high cost of cooling device, achieve the effects of uniform microstructure, increase service life and reduce casting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following specific embodiments will further illustrate the present invention in conjunction with the above-mentioned drawings.

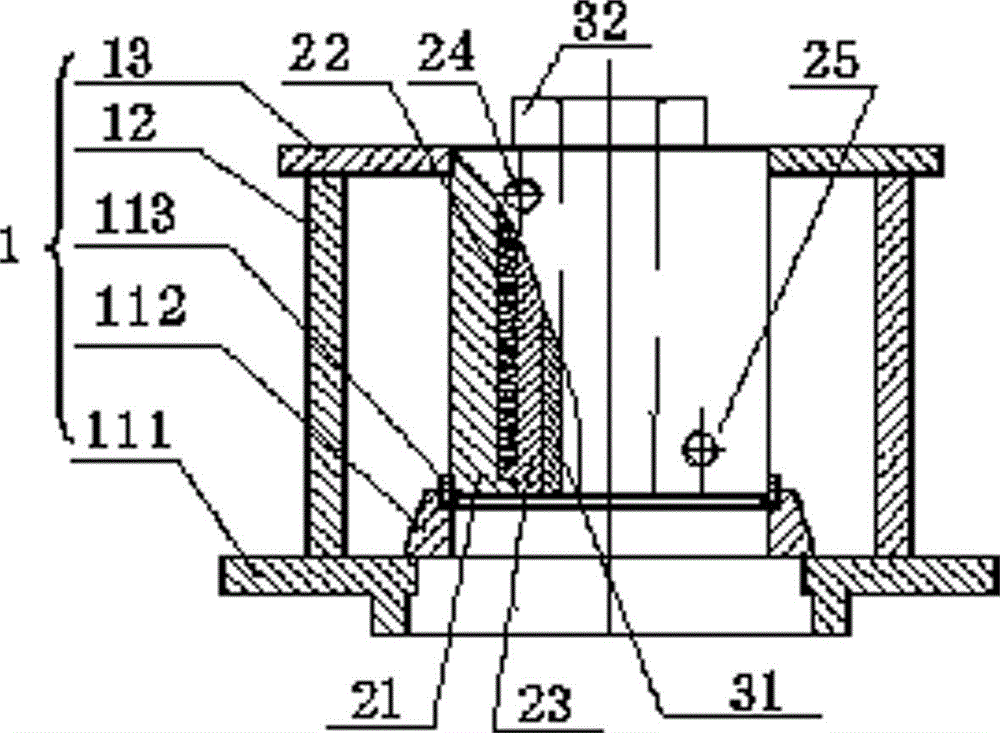

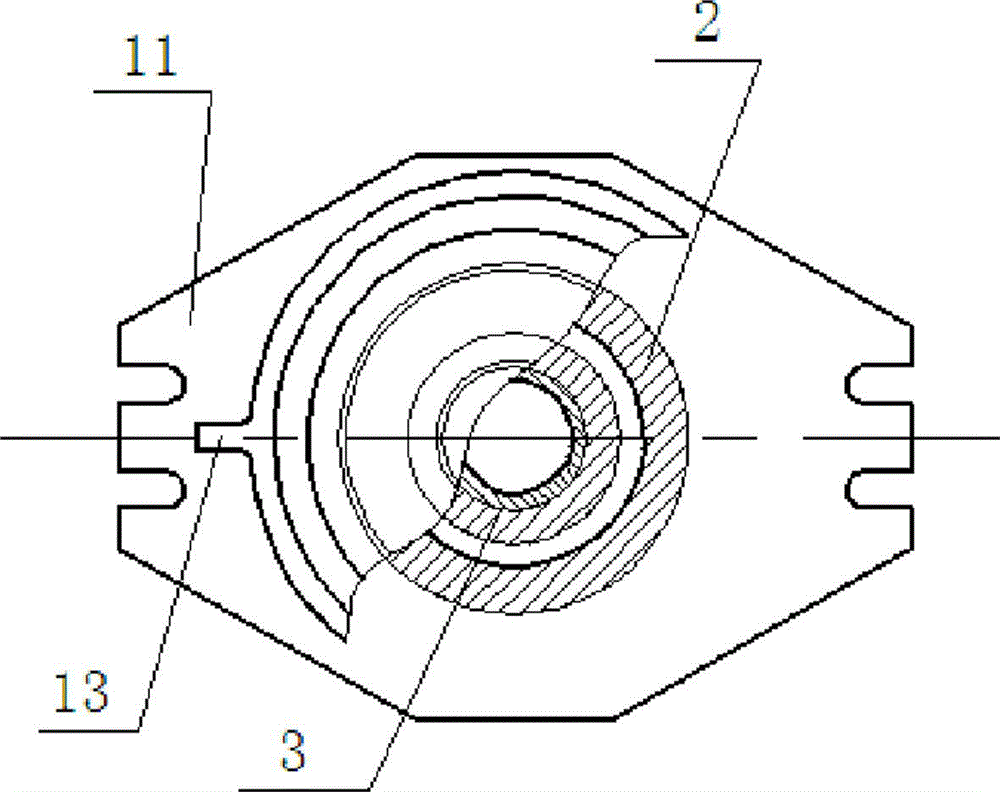

[0011] Such as figure 1 , figure 2 As shown, the present invention provides a kind of horizontal continuous casting crystallizer, comprises fixed frame 1, cooler 2, graphite mold 3; Cooler 2 comprises inner tube 23, outer tube 21; Set between inner tube 23 and outer tube 21 There is a toothed cooling passage 22, and the inner wall of the inner tube 23 is in close contact with the outer wall of the graphite mold 3; the graphite mold 3 is installed in the inner tube 23 of the cooler 2, and the cooler 2 is installed in the fixed frame 1.

[0012] In order to facilitate the installation and disassembly of the crystallizer, the fixed frame 1 includes a base 11, a side plate 12, and a cover plate 13; A central hole is opened on the side plate 12 and the cover plate 13, and the upper end of the outer tube 21 is closely fitted with the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com