Thin billet plate fast-to-replace submerged nozzle

An immersion and nozzle technology, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of unsuitable thin slab continuous casting, etc., and achieve the advantages of reduced risk, good thermal shock resistance and extended life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

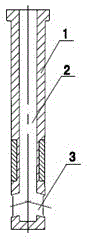

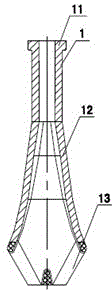

[0018] The invention discloses a quick-change submerged nozzle for thin slabs, such as figure 2 As shown, it includes the nozzle body and the water outlets 13 arranged on both sides of the bottom of the nozzle body.

[0019] Of course, the number and positions of the water outlets can be set as required. Said water outlet 13 can also be provided with one, which is only arranged at the bottom, that is, on the same axis as the inner cavity of the water outlet body.

[0020] The nozzle body includes a straight section 1 arranged at the upper end and a horn section 12 connected to the straight section 1 . The diameter of the inner chamber 11 of the straight section 1 is consistent up and down, and the outer surface is in the shape of a barrel. Such a structure achieves the effect of quick change very well. Specifically, the straight line section 1 is arranged above the slag line layer, and the outer surface profile of the horn section 12 is flat, and the cross section is horn-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com