High-efficiency rough machining method suitable for titanium alloy forge pieces

A titanium alloy and forging technology, which is applied in the field of high-efficiency rough machining of titanium alloy forgings, can solve the problems of low tool life, unobvious economy, and large blade loss, etc., and achieve long tool life, greatly increased economy, and improved tool life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific workpiece is processed using the described titanium alloy high-efficiency roughing method, and its steps include:

[0038] Step 1. Select the blank, which is TC18 forging die material. When selecting, check the material grade TC18, certificate of conformity and furnace batch number, and check whether there are obvious defects in the surface quality.

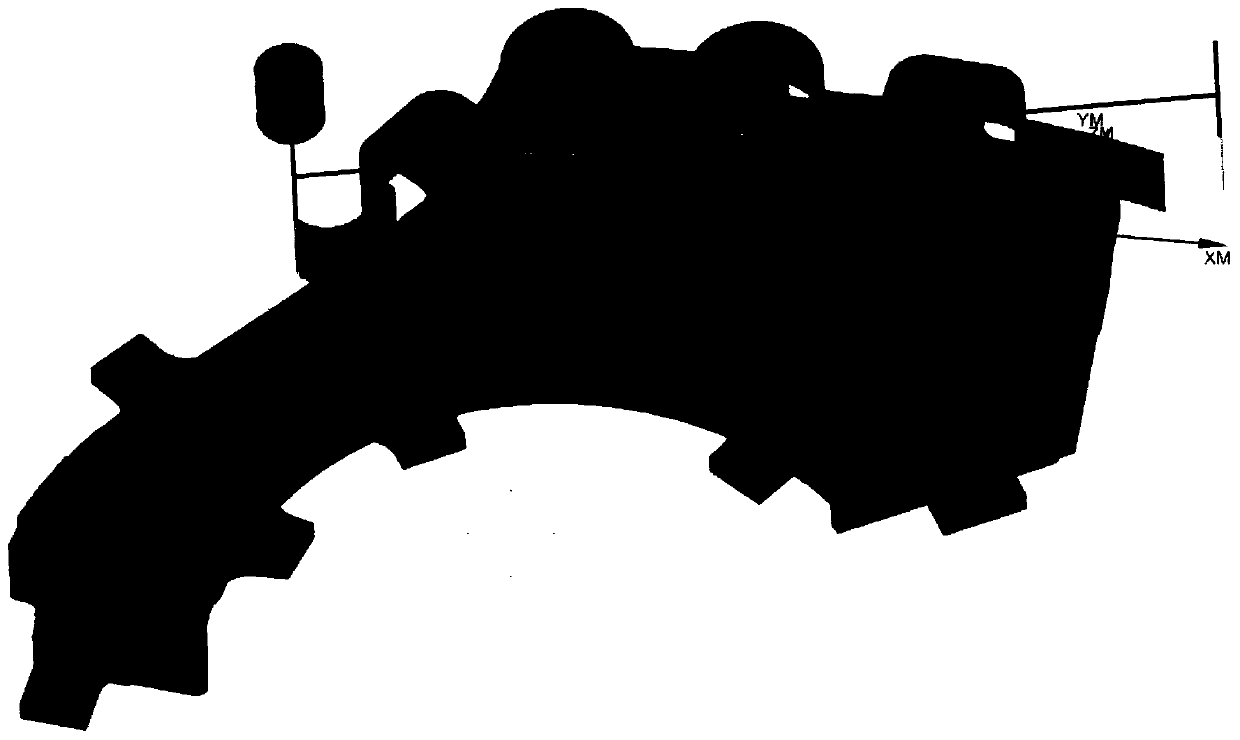

[0039] Step 2: Roughly process the outline of the blank, check the thickness of the blank, the tolerance range is controlled within ±1mm, install the blank on the workbench, support it with a backing plate at the bottom, install a pressure plate around it, and support the corresponding position of the pressure plate with a jack (Such as Figure 5 ), the flatness of the large plane surface shall not exceed 1mm, and the processing method of the remaining material in the blank processing is pre-designed, which is wire cutting or milling. During wire cutting, the remaining material is too large and can be processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com