Combustion adjusting method for corner tangential pulverized coal furnace based on 3H air volume control method model

A combustion adjustment and air volume control technology, which is applied in the direction of combustion control, combustion method, combustion chamber, etc., can solve the problems of less working conditions, data distortion, and inability to reflect the combustion situation of the burner area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

[0067] Take Lae City Power Plant as an example:

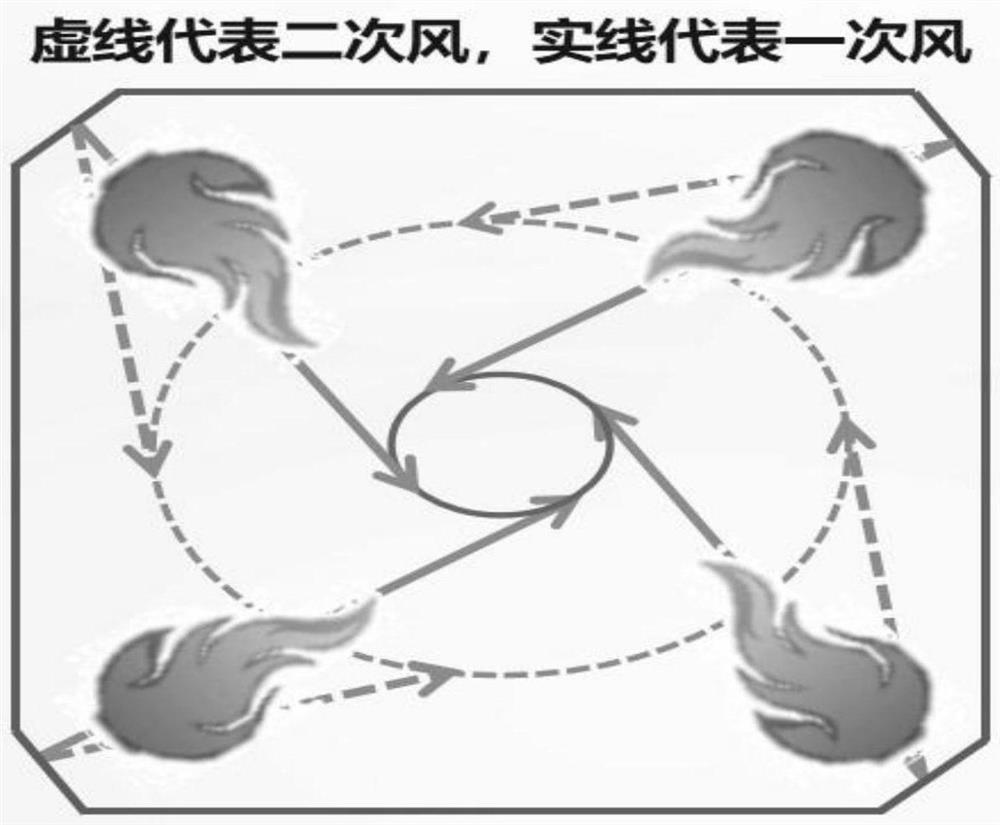

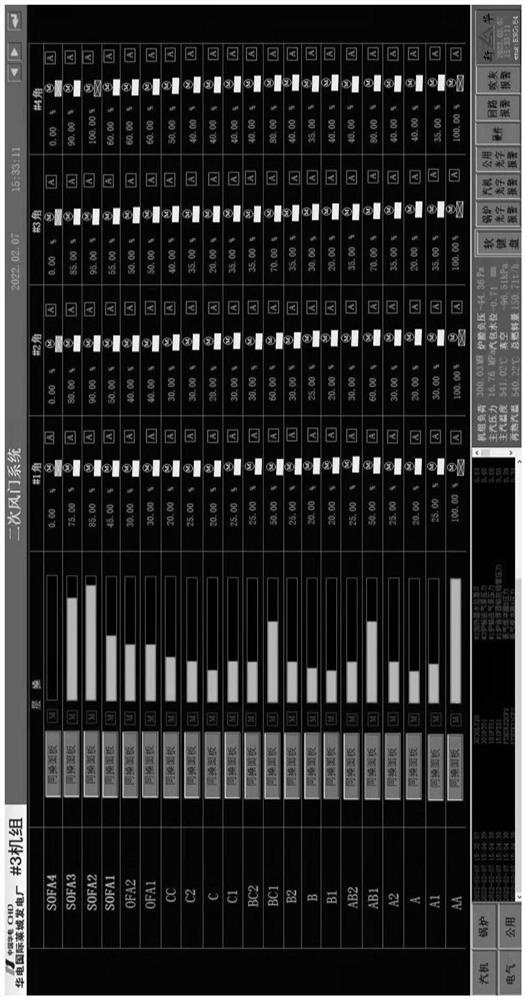

[0068] (1) Theoretical demonstration of "3H air volume control method"

[0069] The boilers #1-#4 of Laicheng Power Plant use the four-corner tangential combustion method. There are two types of air used for the boiler combustion, namely the primary air carrying pulverized coal and the secondary air such as auxiliary air, perimeter air, oil layer air, etc., and the primary air is mixed The pulverized coal enters the boiler and is pulled by the high-momentum secondary air, sucking up the high-temperature flue gas, and the pulverized coal is directly impacted by the high-temperature flame swept from the upstream adjacent corner for combustion. Nitrogen oxide content in flue gas and car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com