Patents

Literature

31results about How to "Bring convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

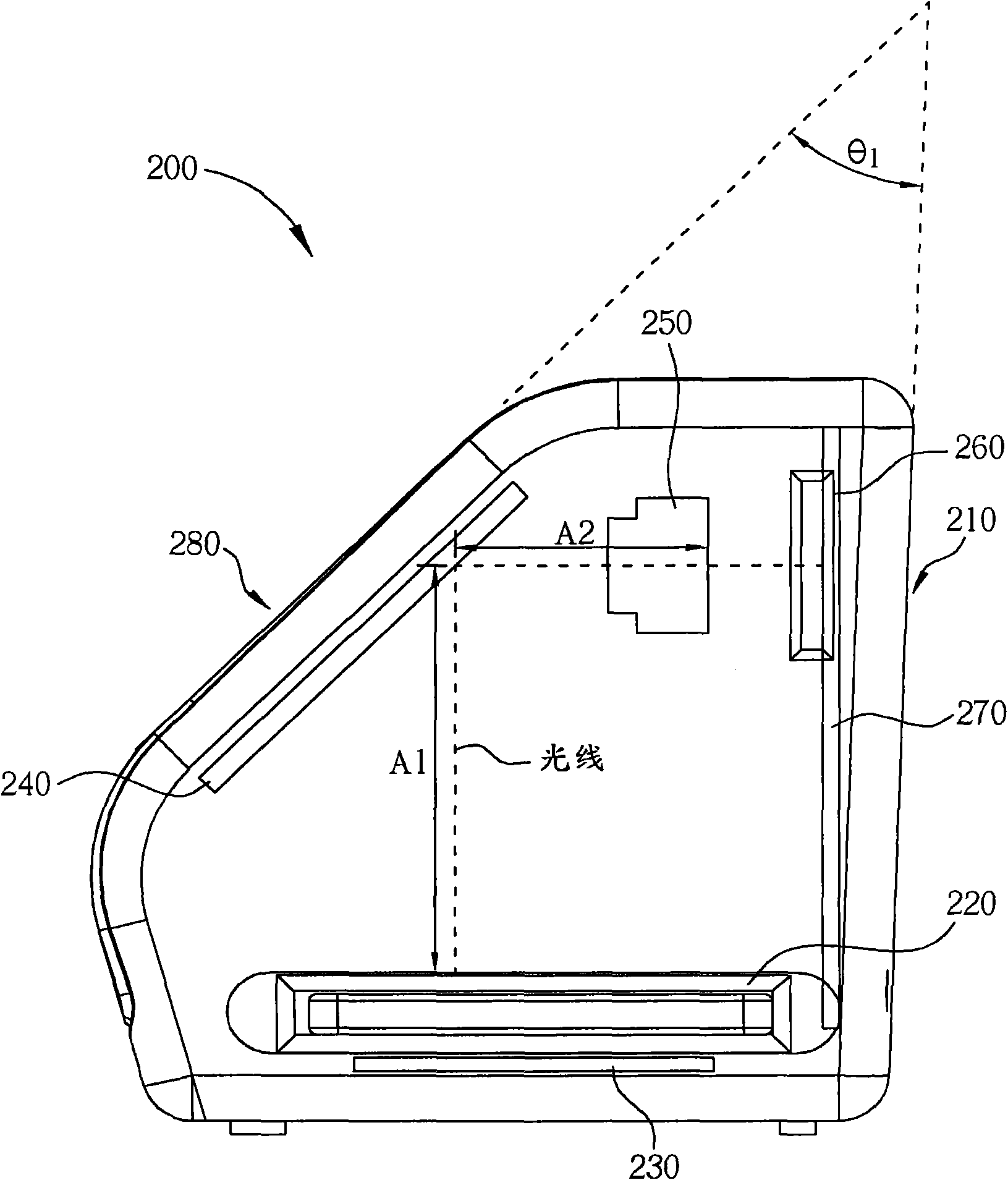

User interface for mobile devices

ActiveUS20090197615A1Maximize useBring convenienceInput/output for user-computer interactionPower managementHuman–computer interactionMobile device

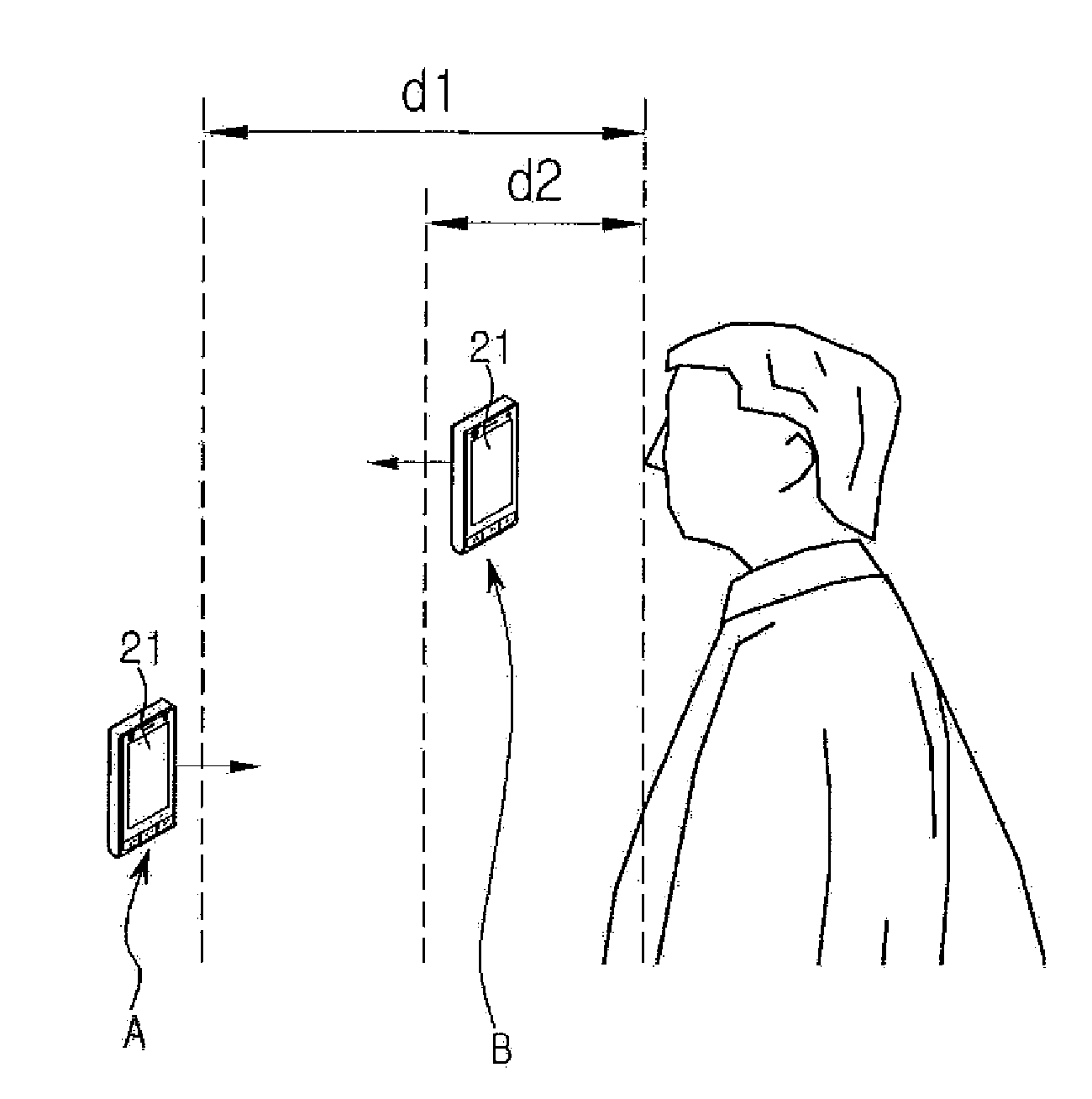

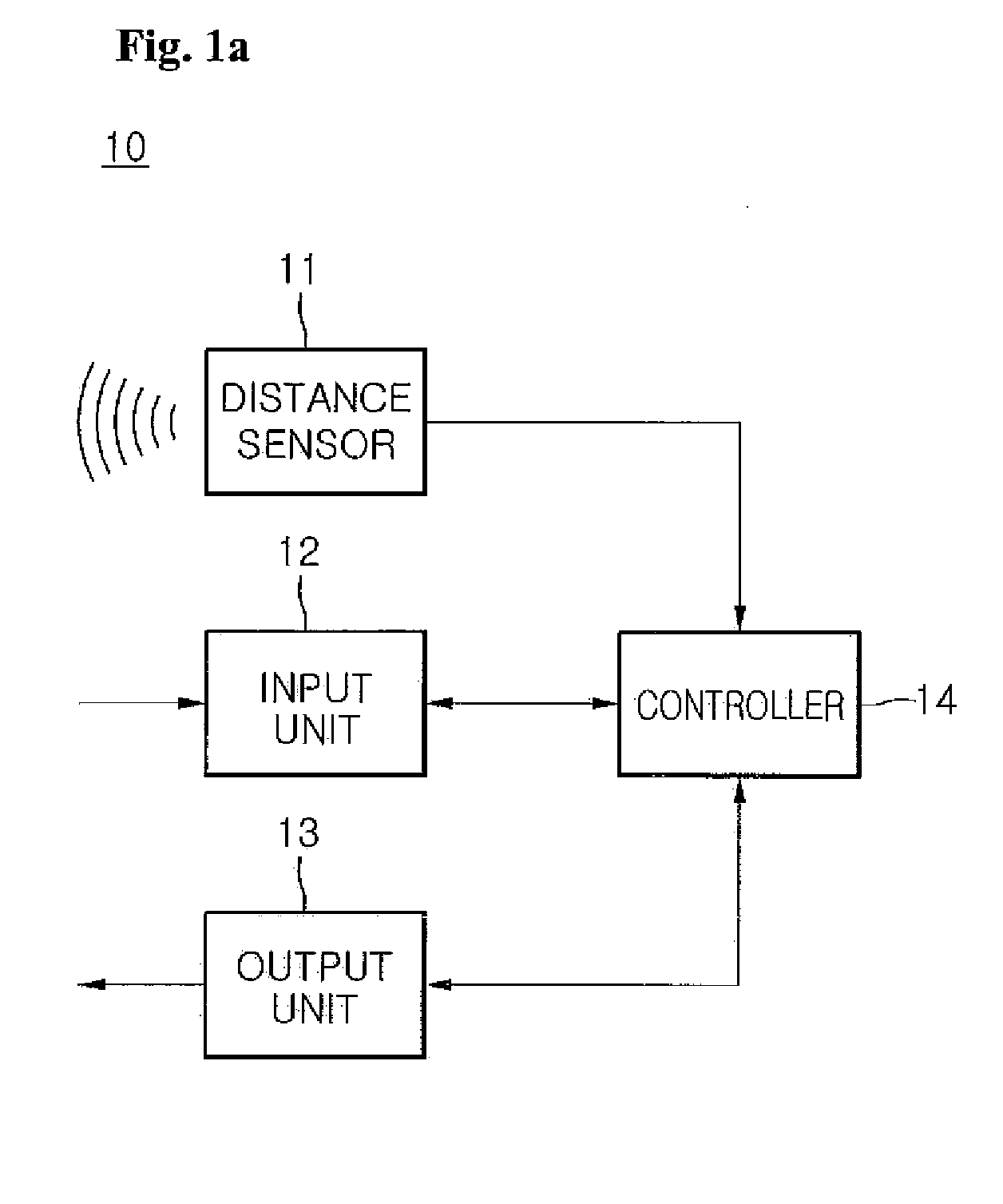

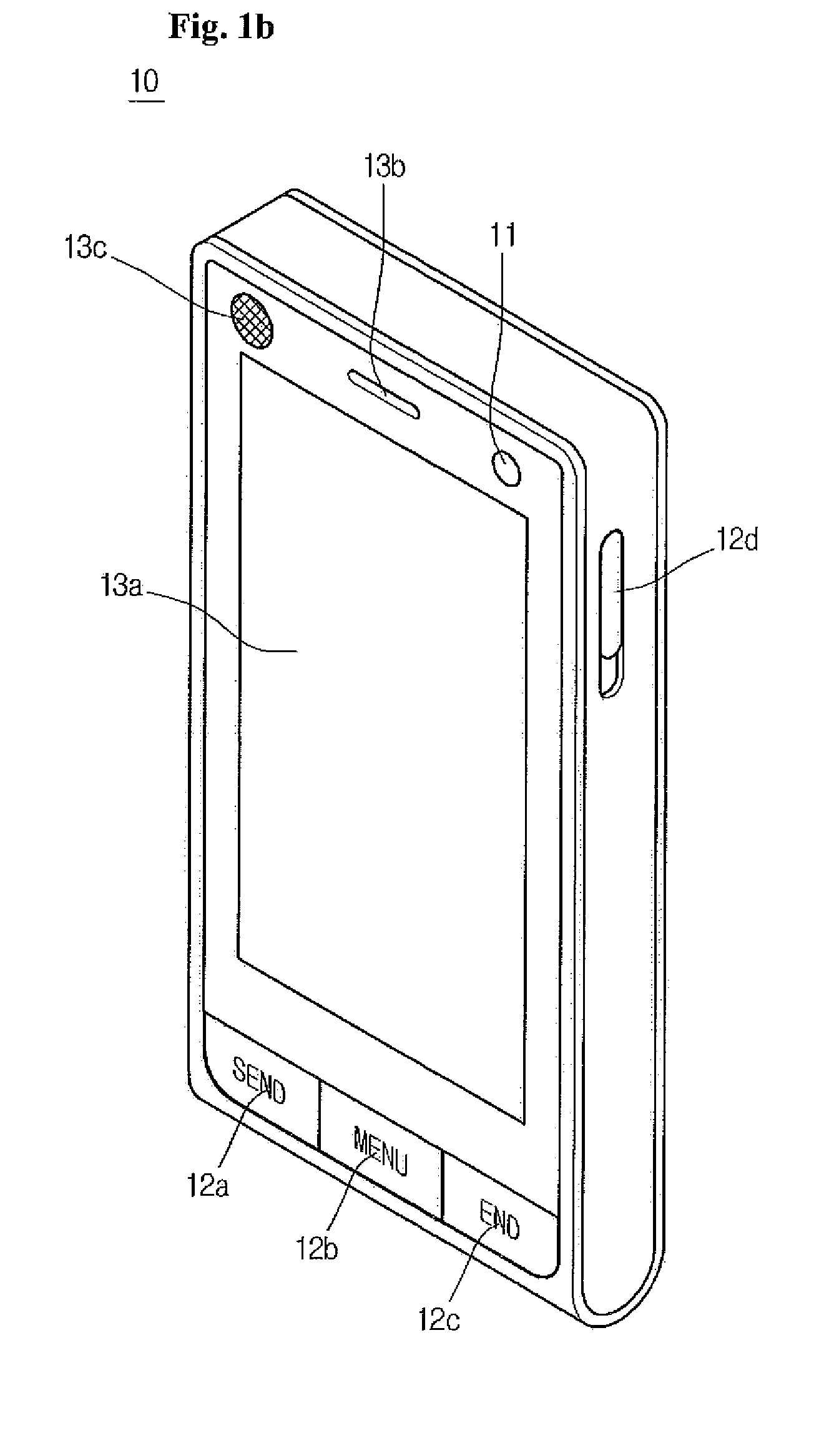

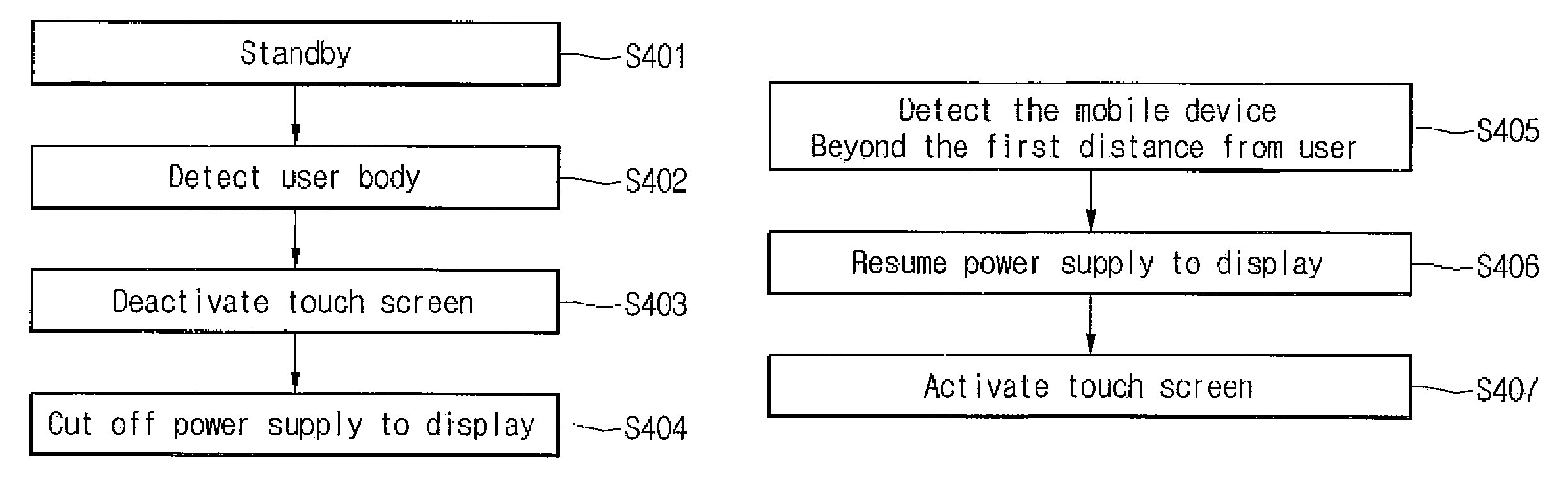

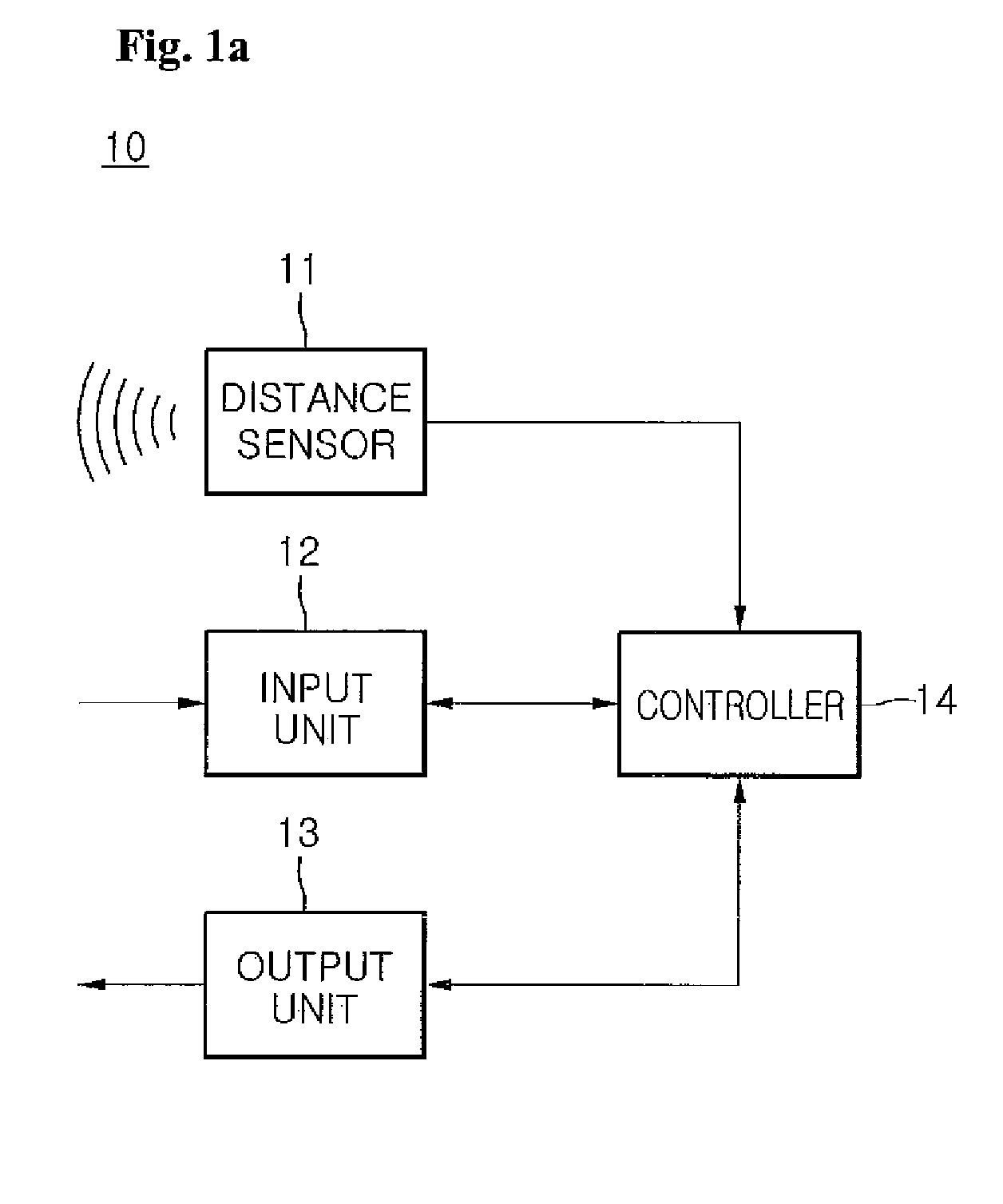

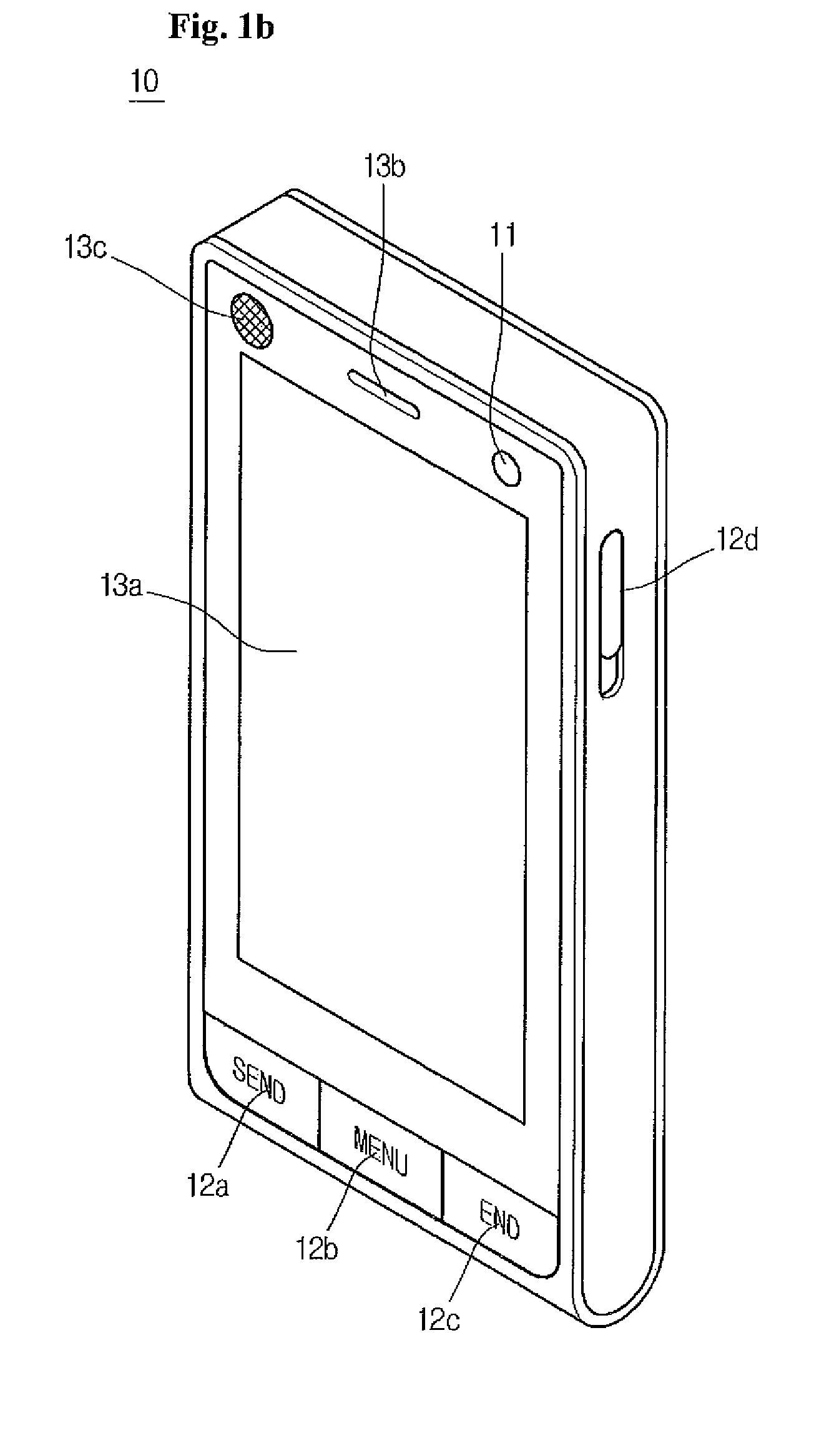

A device and method for controlling the user interface of a mobile device, are discussed. According to an embodiment, the method includes determining a distance relationship between a user's body and the mobile device, and changing a configuration of at least one of at least one input unit and at least one output unit depending upon the determined distance relationship.

Owner:LG ELECTRONICS INC

User interface for mobile devices

ActiveUS8195220B2Maximize useBring convenienceInput/output for user-computer interactionPower managementMobile deviceHuman–computer interaction

A device and method for controlling the user interface of a mobile device, are discussed. According to an embodiment, the method includes determining a distance relationship between a user's body and the mobile device, and changing a configuration of at least one of at least one input unit and at least one output unit depending upon the determined distance relationship.

Owner:LG ELECTRONICS INC

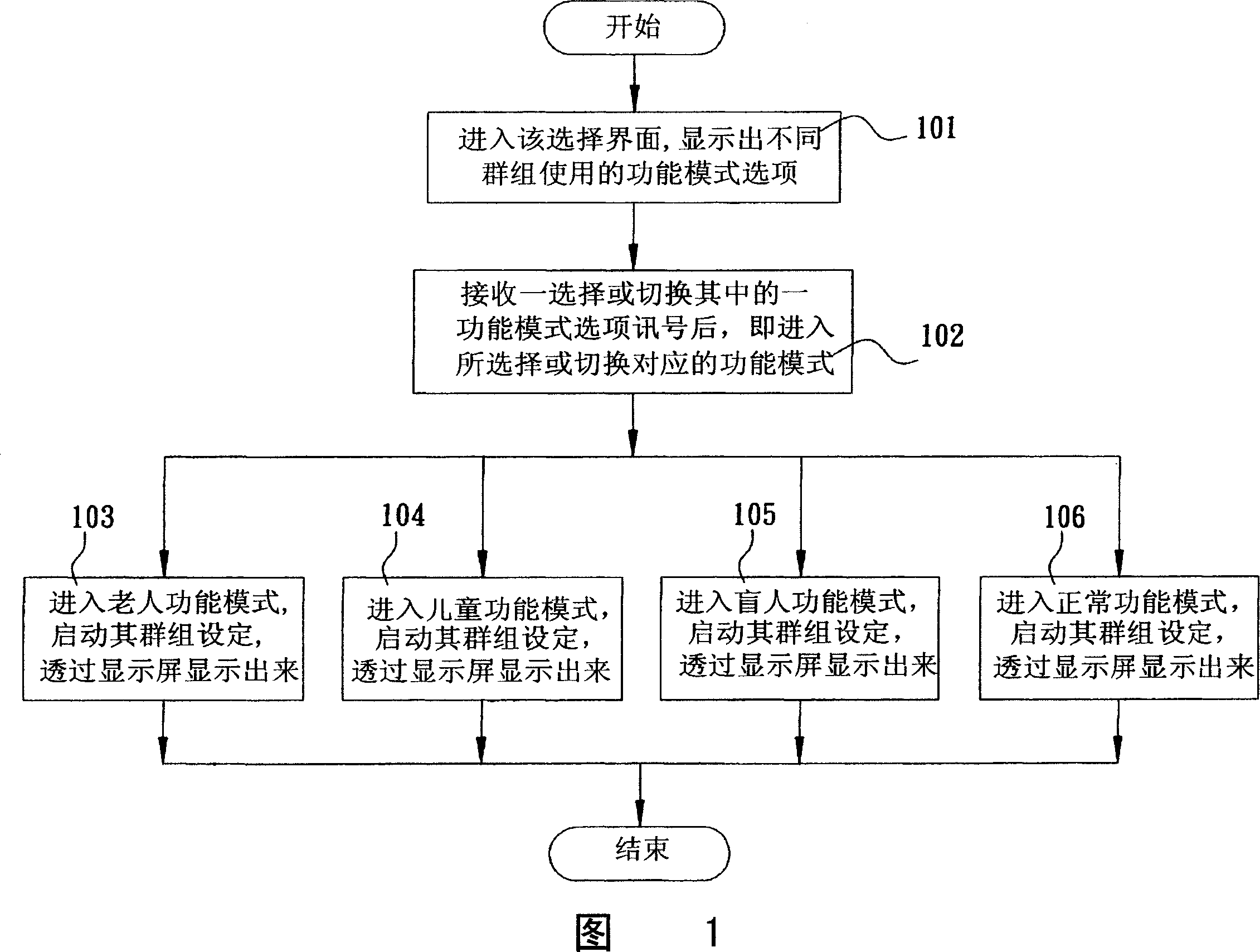

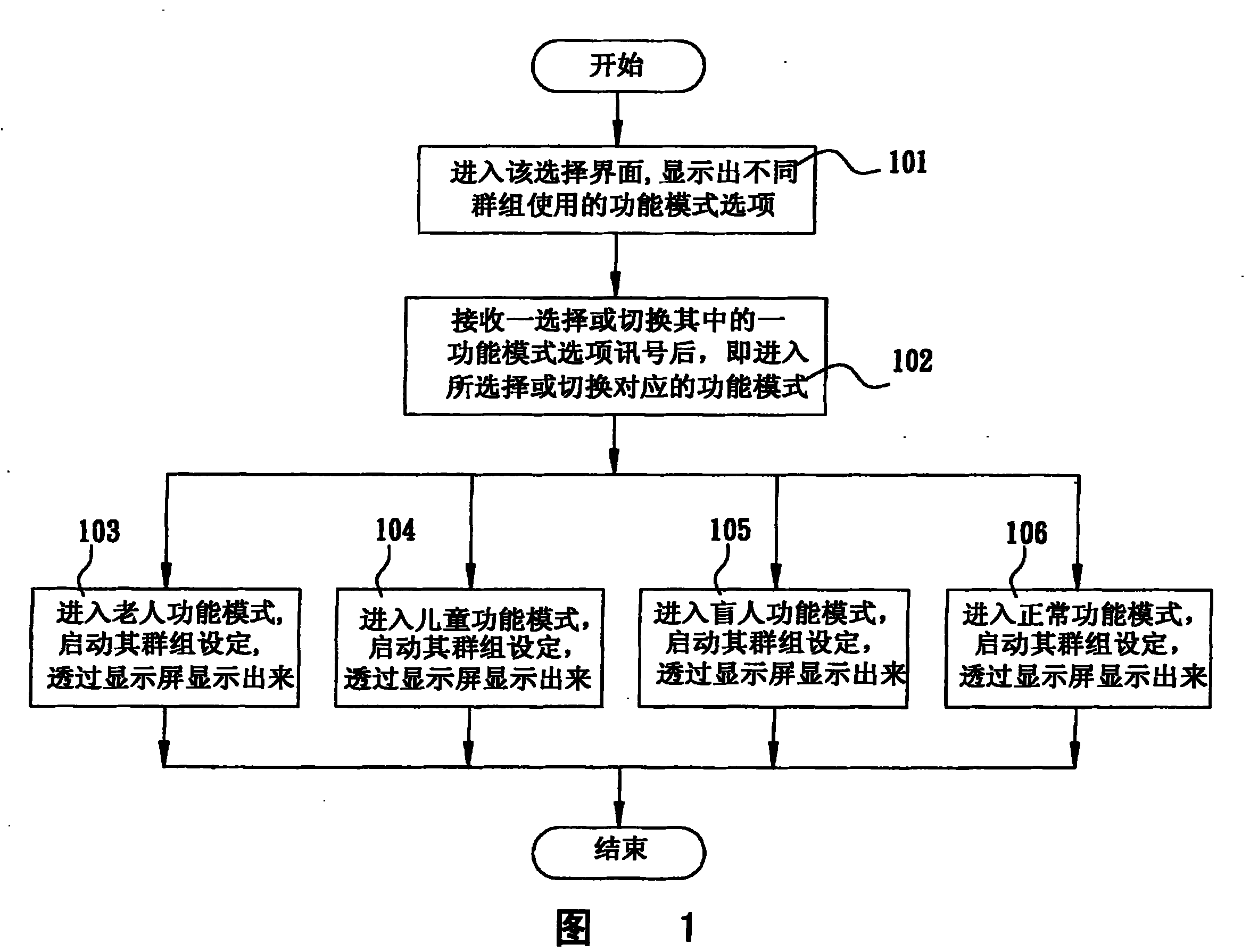

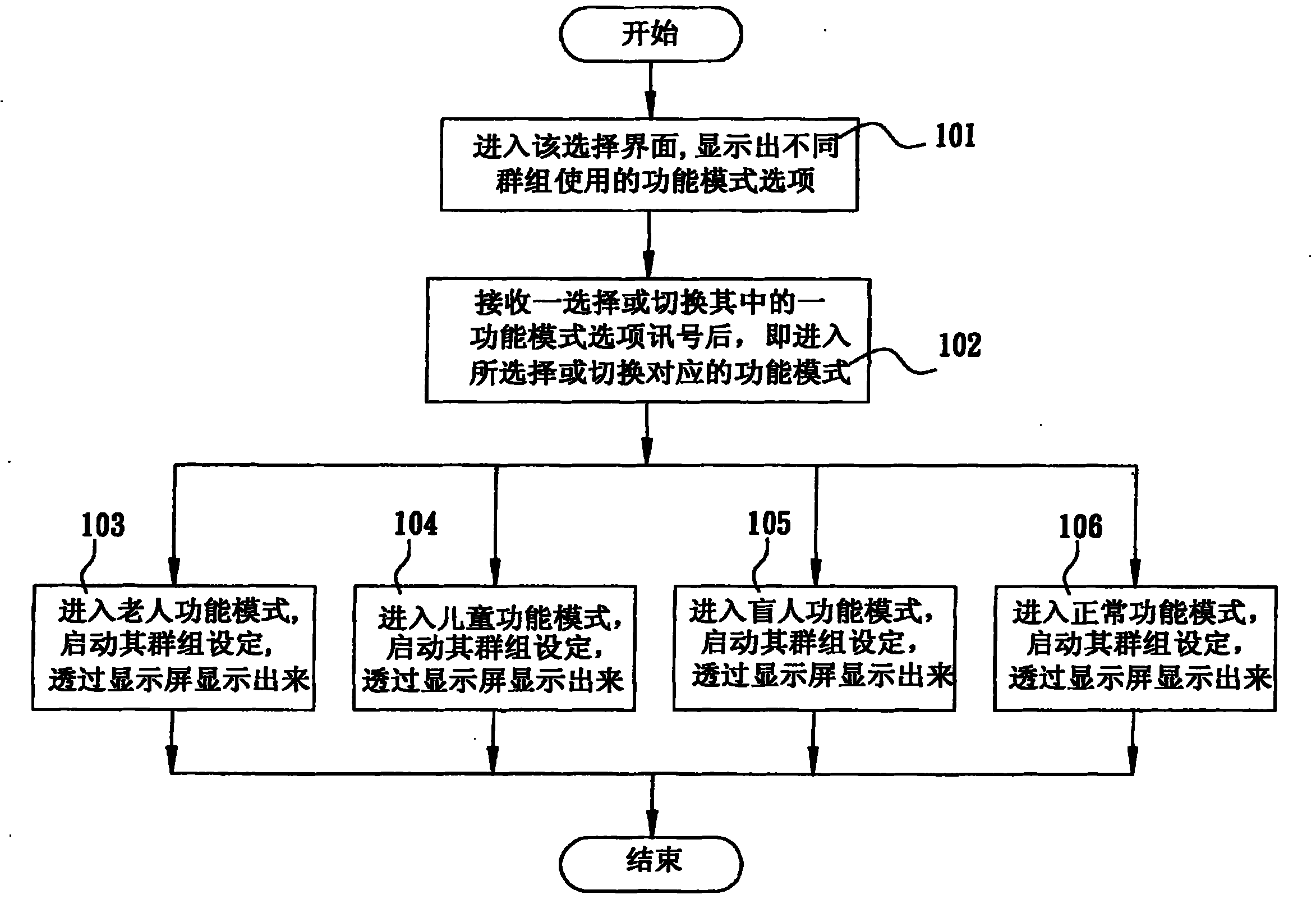

Functional mode switching method for providing different group use in cell phone

ActiveCN101005525AAdded value can be addedReduce development costsRadio/inductive link selection arrangementsTelephone sets with user guidance/featuresHuman–computer interactionGroup setting

The method comprises: setting a built-in selection menu in mobile phone; the selection menu is displayed on a display screen of the mobile phone; in the selection menu there are selectable function modes items for use in different groups; the function mode items comprises at least a elder function mode, a children function mode and a blind-man function mode. After a user (elder, child or blind-man) selects one function mode item, the mobile phone enters into the selected function mode, opens the group setting of the function mode and displays it through display screen.

Owner:INVENTEC(NANJING) TECH CO LTD

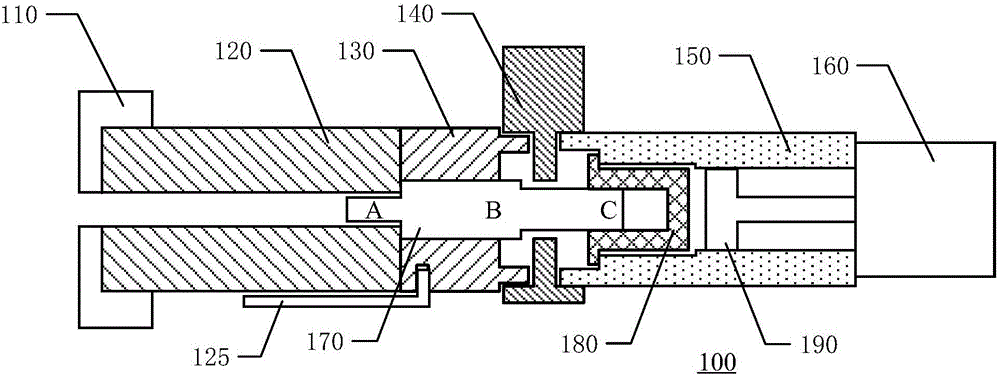

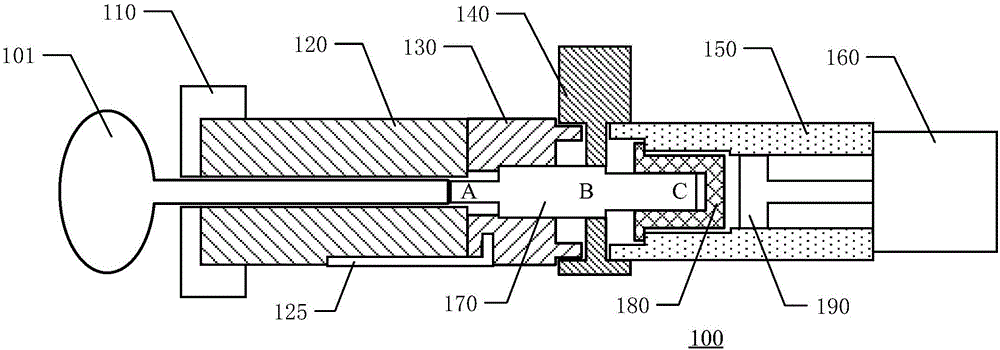

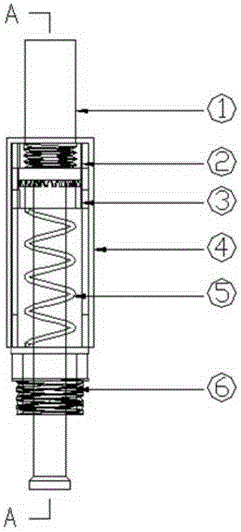

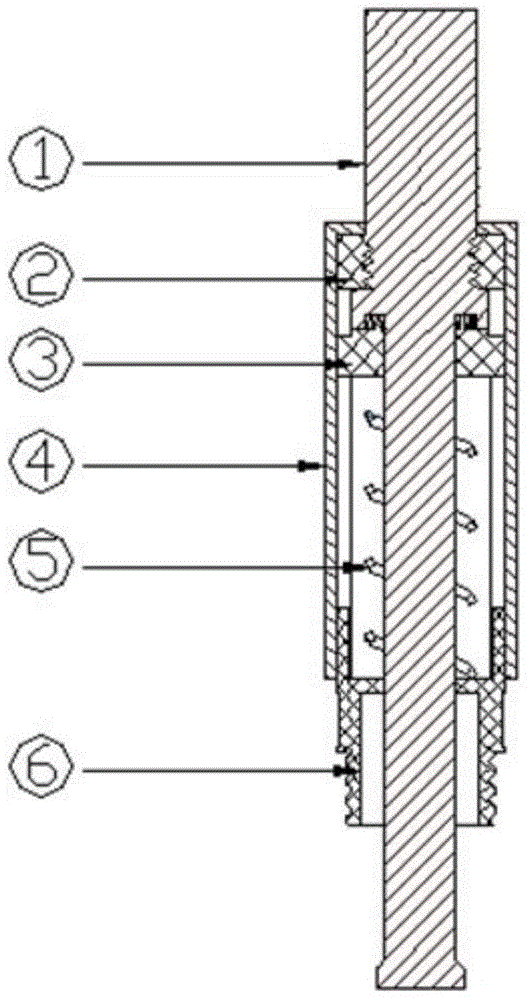

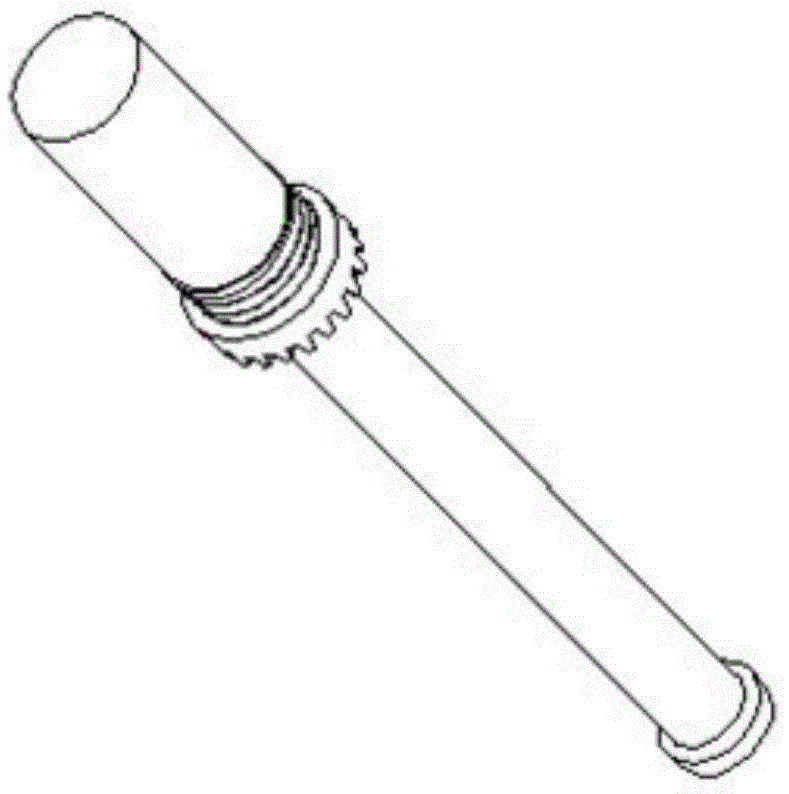

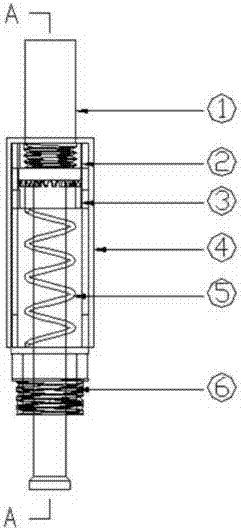

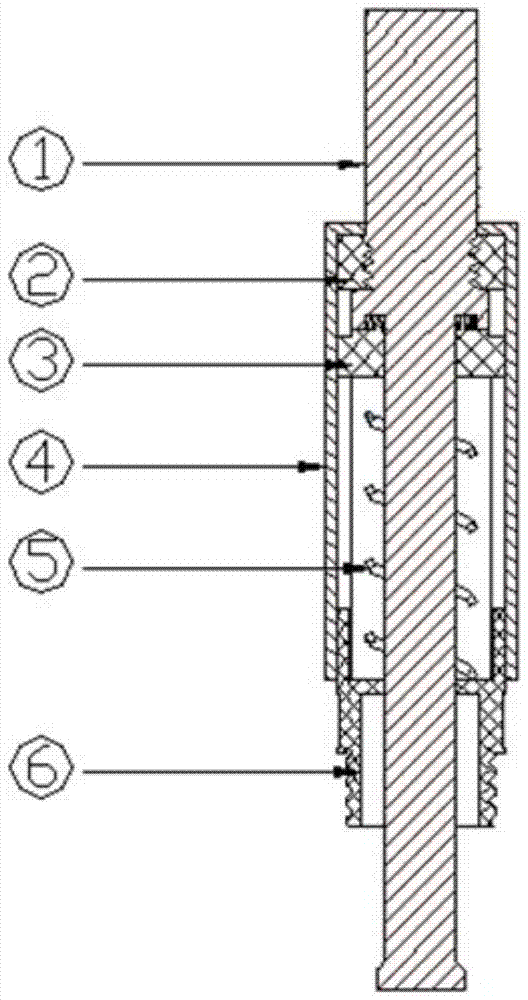

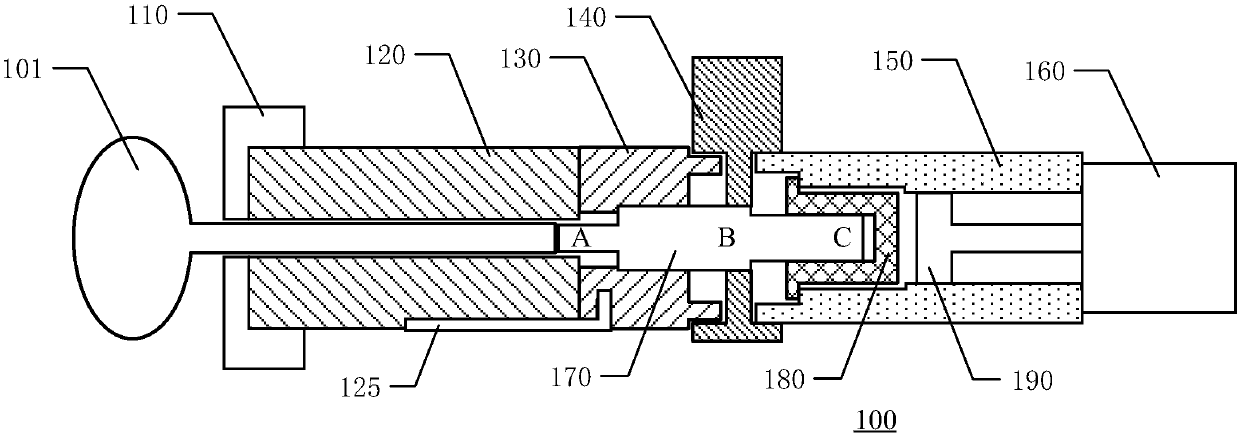

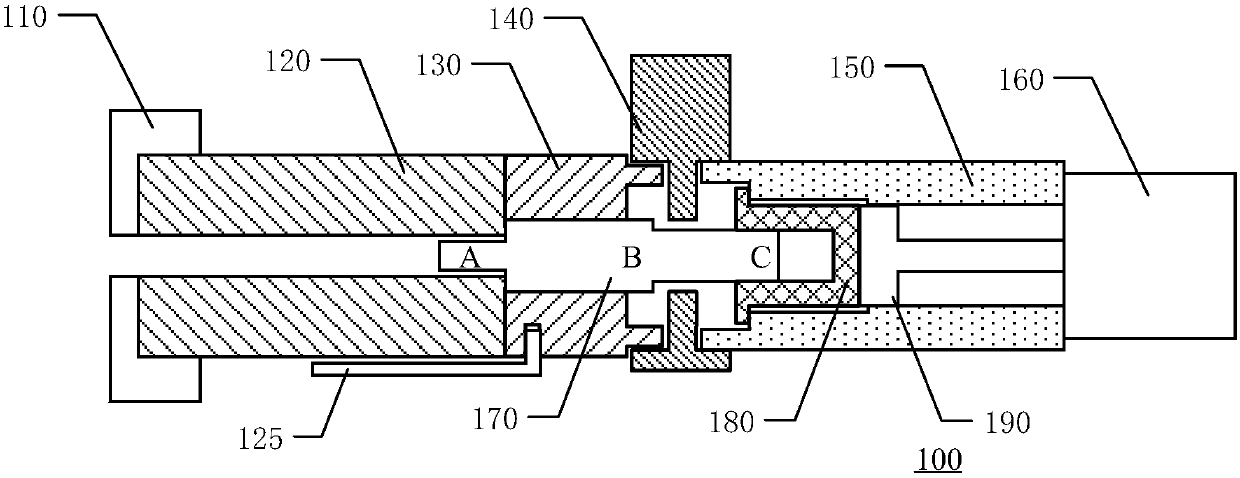

Electronic lock cylinder device

ActiveCN106121379AImprove securityCompact cylinder structureNon-mechanical controlsHandle fastenersEngineeringControl circuit

The invention discloses an electronic lock cylinder device. The electronic lock cylinder device comprises a front handle, a lock container, a main shaft, a second connector, a second coupler and a hand wheel which are assembled together in the axial direction, wherein the front handle is fixedly connected with the lock container; the second coupler is fixedly connected with the hand wheel; the main shaft penetrates through a central hole of the hand wheel; when a lock is locked, the second connector freely rotates relative to at least one of the second coupler and the main shaft; when the electronic lock is unlocked, the second connector, the second coupler and the main shaft rotate together; and when the front handle is rotated, the lock container, the main shaft, the second connector and the second coupler sequentially rotate, the hand wheel is rotated, and the lock is unlocked. According to the electronic lock cylinder device, the front handle and a control circuit are respectively arranged at the two ends of the main shaft, so that the utilization convenience, reliability and safety of the electronic lock cylinder are improved.

Owner:朱英华

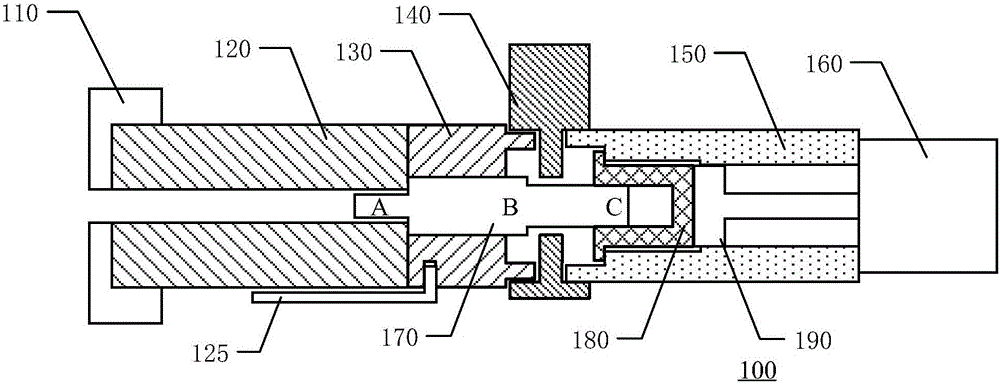

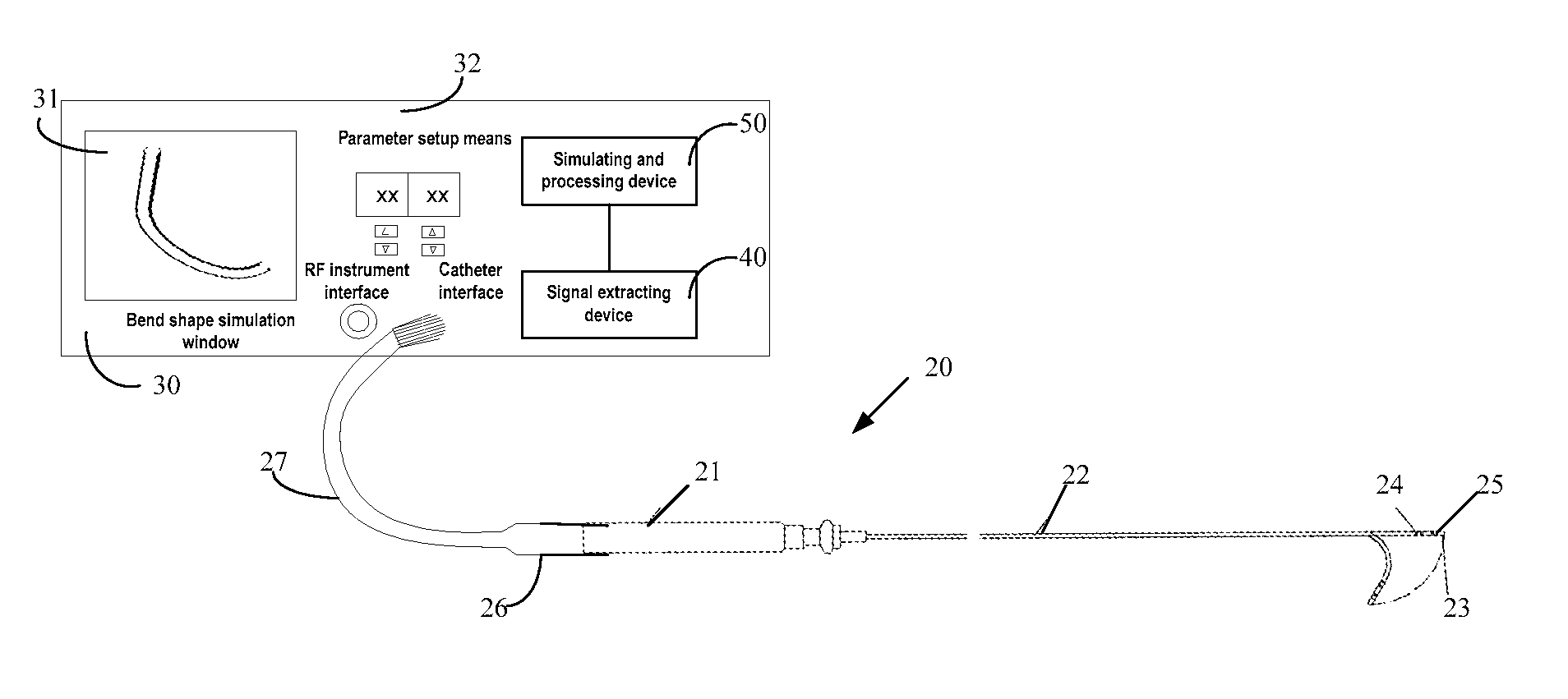

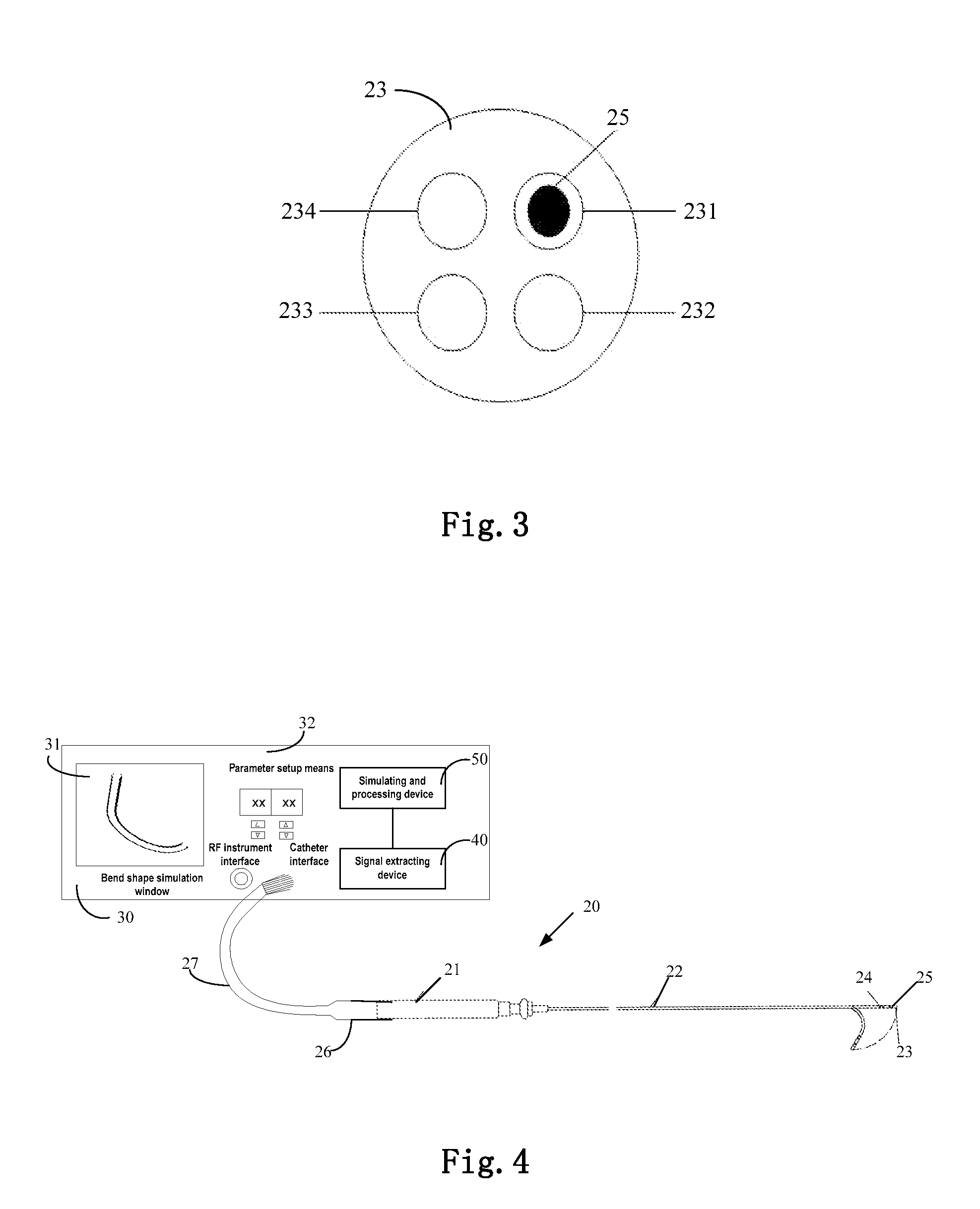

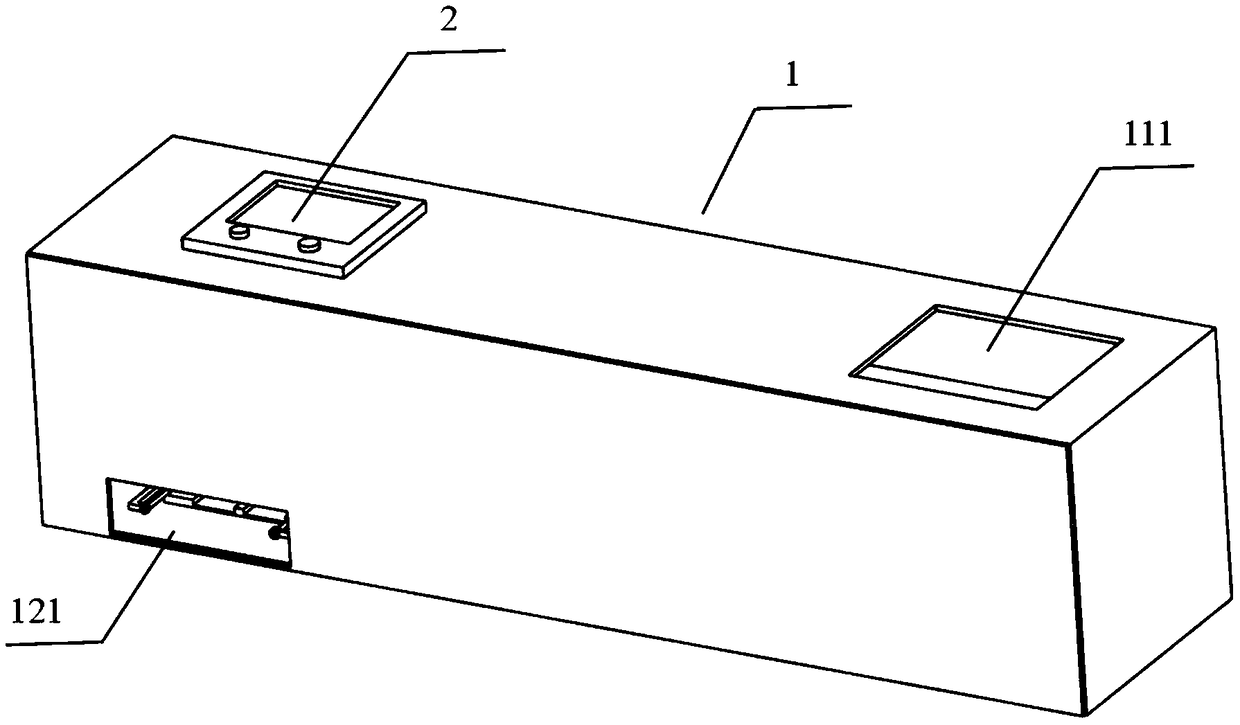

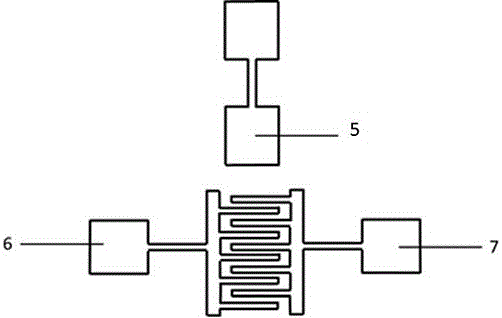

Method for simulating bend shape of catheter and magnetic induction catheter

InactiveUS20110313414A1Bring convenienceImprove controllabilitySurgical navigation systemsMedical devicesPower flowMagnetic line

A method for simulating the bend shape of a catheter (20) includes providing at least two sensor elements (24,25) in the catheter (20), and said sensor elements (24,25) traverse magnetic line of force to generate induced current. Space information of the sensor elements (24,25) is extracted from the induced current information, and the bend shape of the catheter (20) is calculated according to aforementioned space information in combination with characteristic information of the catheter (20). A catheter (20) includes a catheter body (22), at least two magnetic sensors (24,25), a signal extracting device (40), and a simulating and processing device (50).

Owner:SHANGHAI MICROPORT EP MEDTECH CO LTD

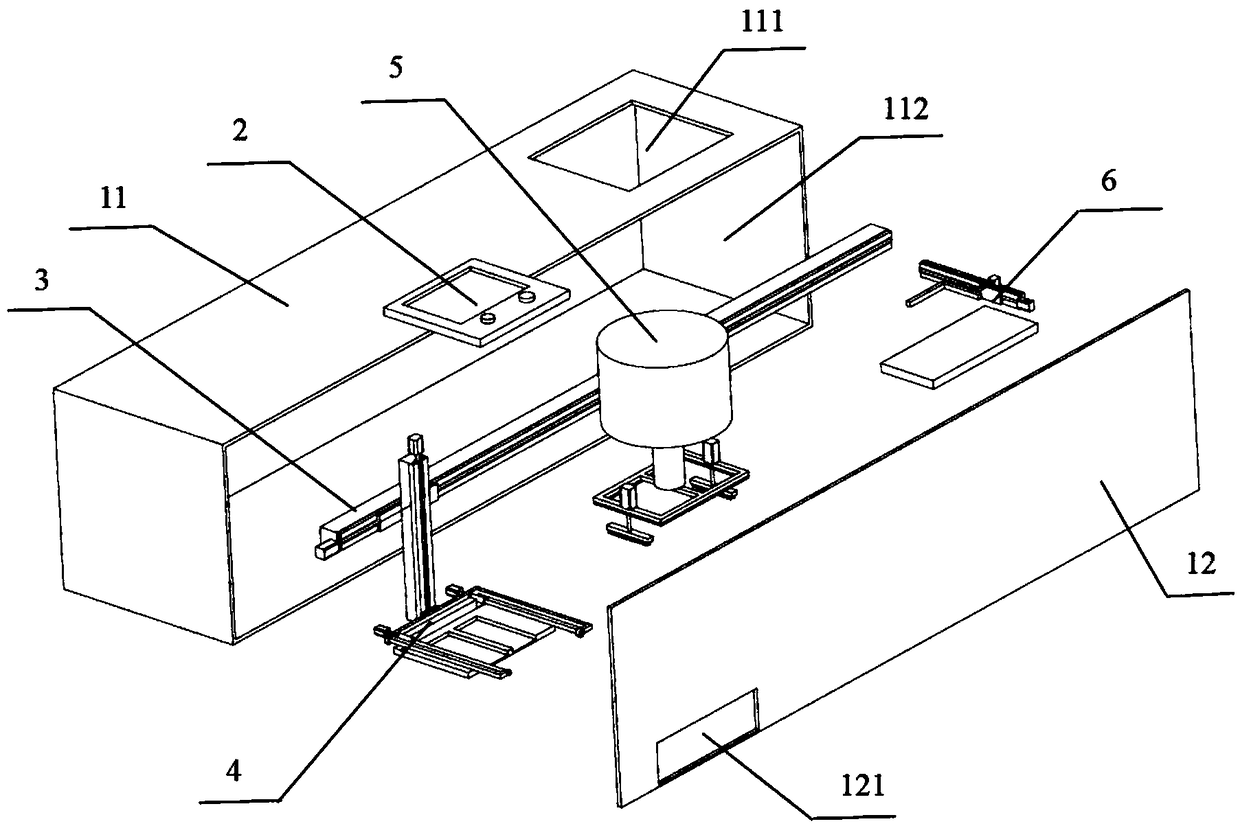

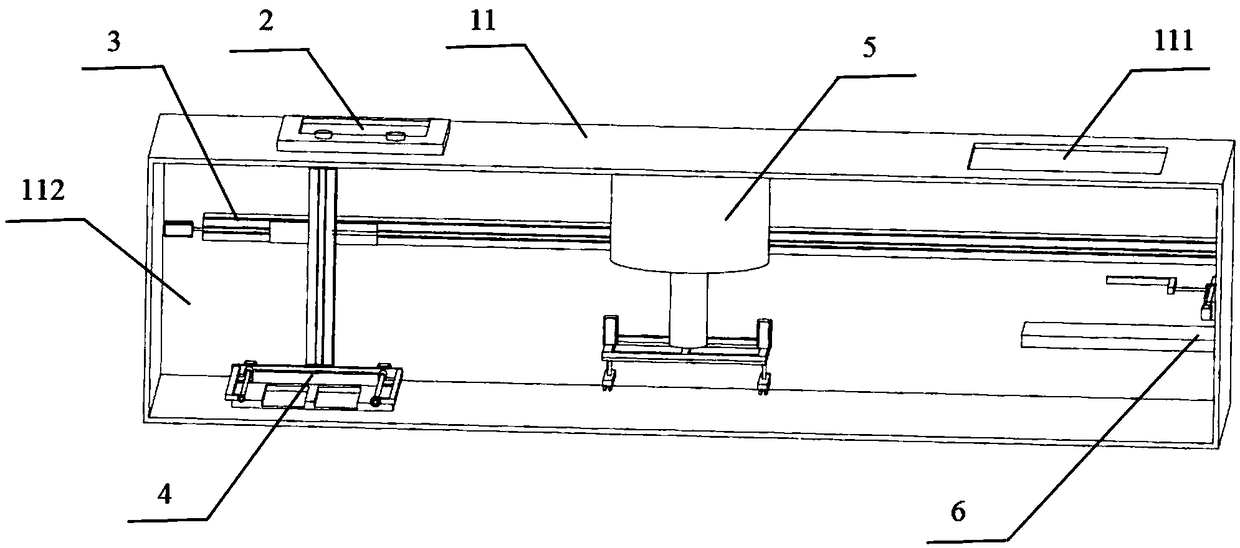

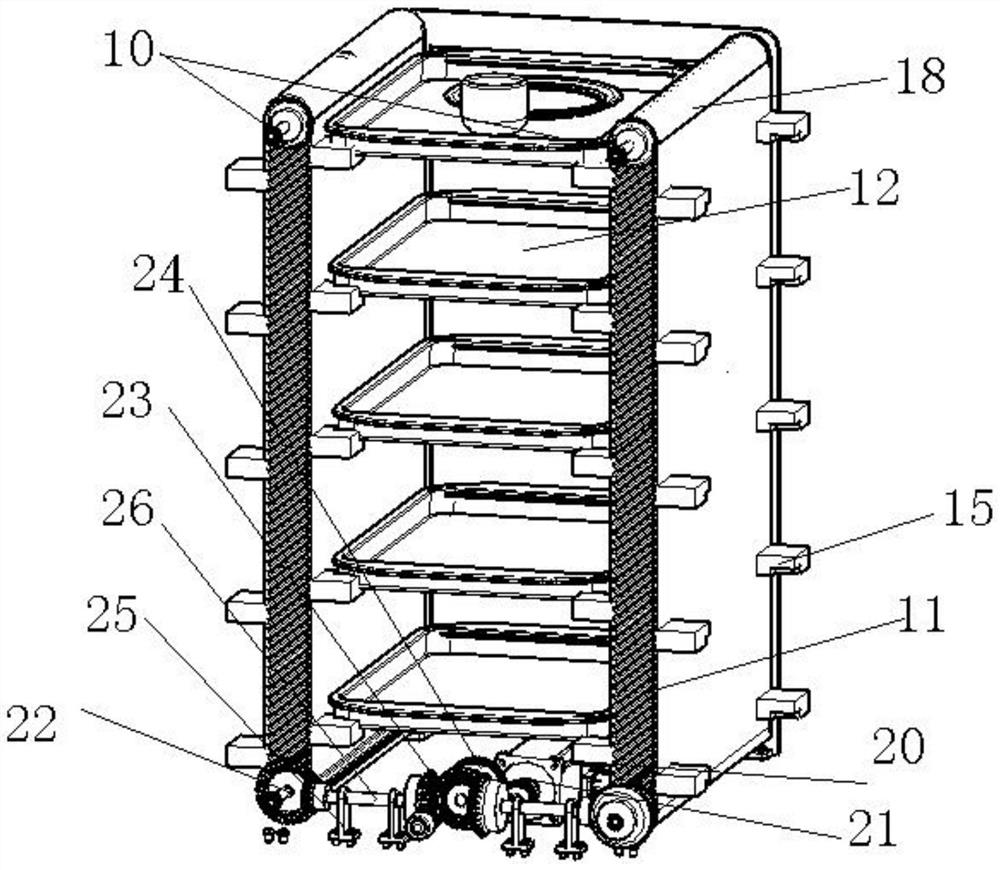

Intelligent cleaning and storing shoe cabinet

ActiveCN109452775AImprove efficiencyShorten the timeWardrobesFootwear cleanersEngineeringTerminal equipment

The invention discloses an intelligent cleaning and storing shoe cabinet. The intelligent cleaning and storing shoe cabinet comprises a shell, a shoe taking opening, a shoe storing opening, an X-axisguide rail, a telescoping lifting mechanism, a polishing and brushing mechanism, a pushing and storing mechanism and a controller, wherein a cavity is formed in the shell, the shoe taking opening is formed in one end on the upper surface of the shell, the shoe storing opening is formed in the end, away from the shoe taking opening, on the side face of the shell, the controller is arranged on the upper surface of the shell, and the X-axis guide rail is arranged on the side wall of the internal wall of the shell and is opposite to the shoe storing opening. The telescoping lifting mechanism is slidably connected with the X-axis guide rail, the polishing and brushing mechanism is arranged on the upper surface of the inner wall of the shell, the pushing and storing mechanism is arranged on oneside wall of the internal wall of the shell and located under the shoe taking opening, and the controller is separately electrically connected with the X-axis guide rail, the telescoping lifting mechanism, the polishing and brushing mechanism and the pushing and storing mechanism. The intelligent cleaning and storing shoe cabinet has the function of automatically storing and brushing leather shoes, a user selects leather shoes by making external mobile terminal equipment connected with the shoe cabinet, and convenience is brought to the user.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

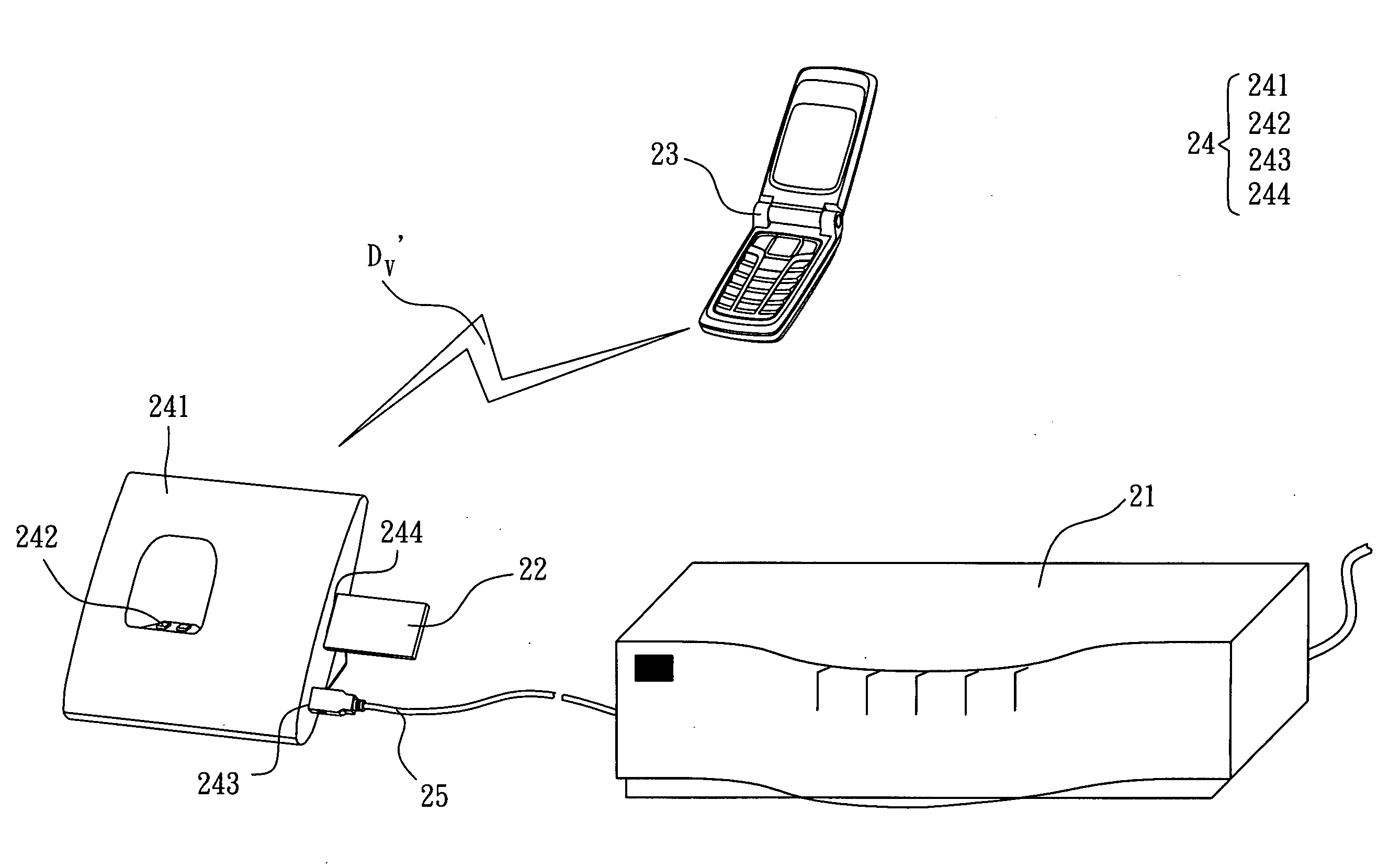

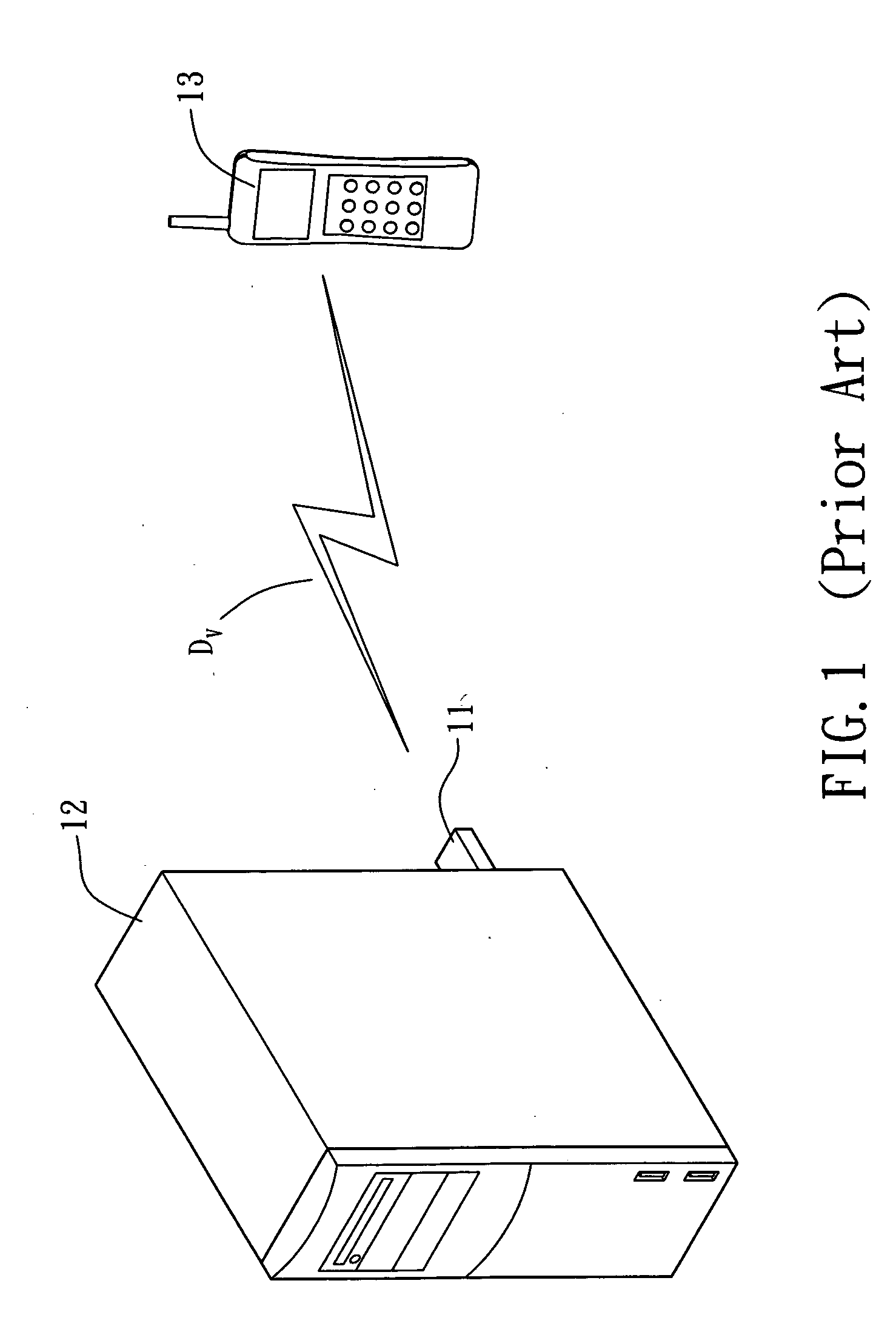

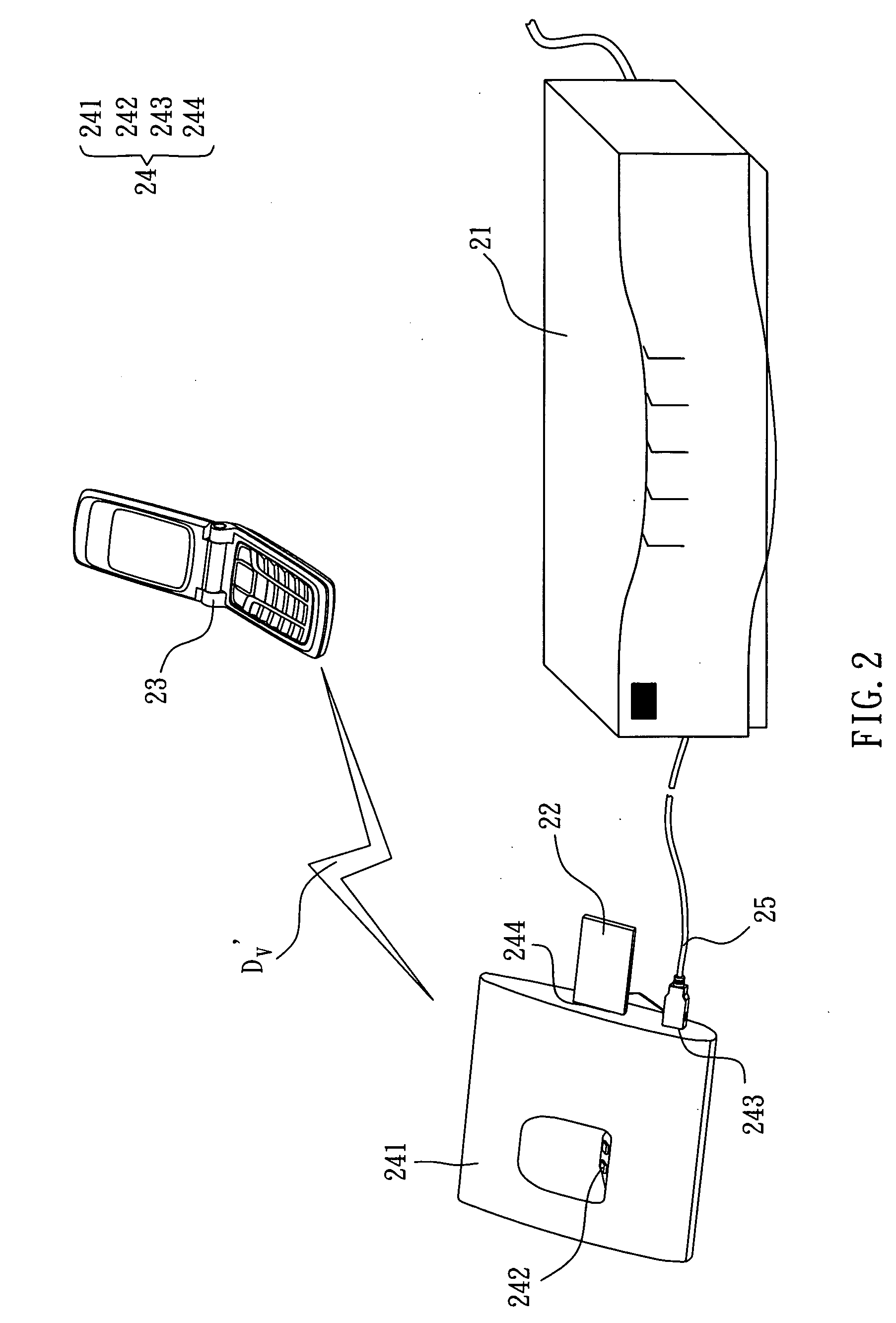

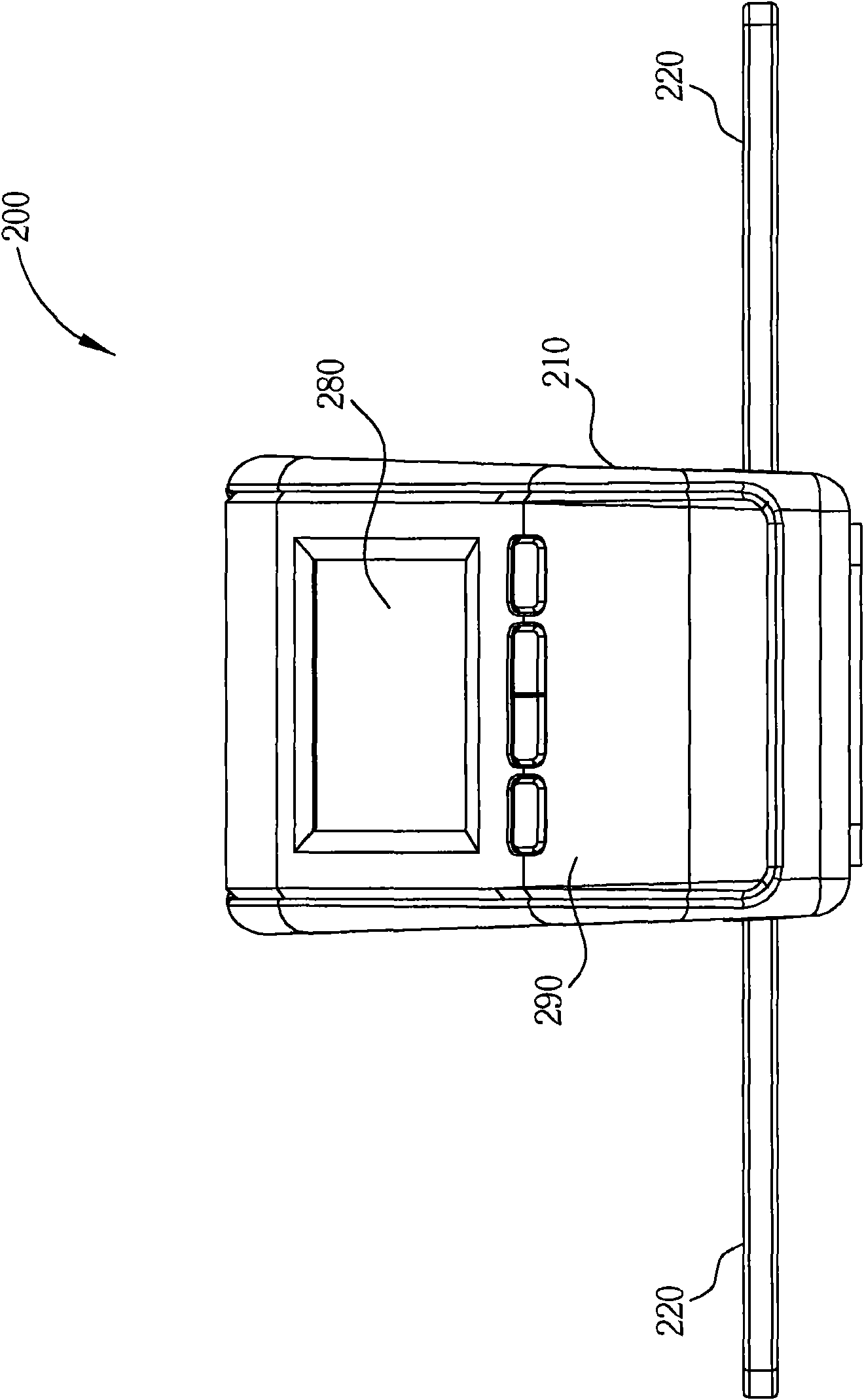

Wireless communication system and charging base thereof

InactiveUS20080064449A1Quality improvementAvoid problemsTransmissionTelephone set constructionsWireless communication protocolCommunications system

A wireless communication system includes a charging base, a phone, a computer host and a wireless communication module. The charging base has a charging socket, a data transmission port and a wireless communication socket. The wireless communication socket is electrically connected with the data transmission port. The phone inserts in the charging socket of the charging base to be charged. The computer host is electrically connected with the data transmission port of the charging base through a transmission cable. The wireless communication module inserts in the wireless communication socket of the charging base and communicates with the phone according to a wireless communication protocol. When the phone transmits information, the wireless communication module receives the information and transmits it to the computer host through the data transmission port and the transmission cable.

Owner:ASUSTEK COMPUTER INC

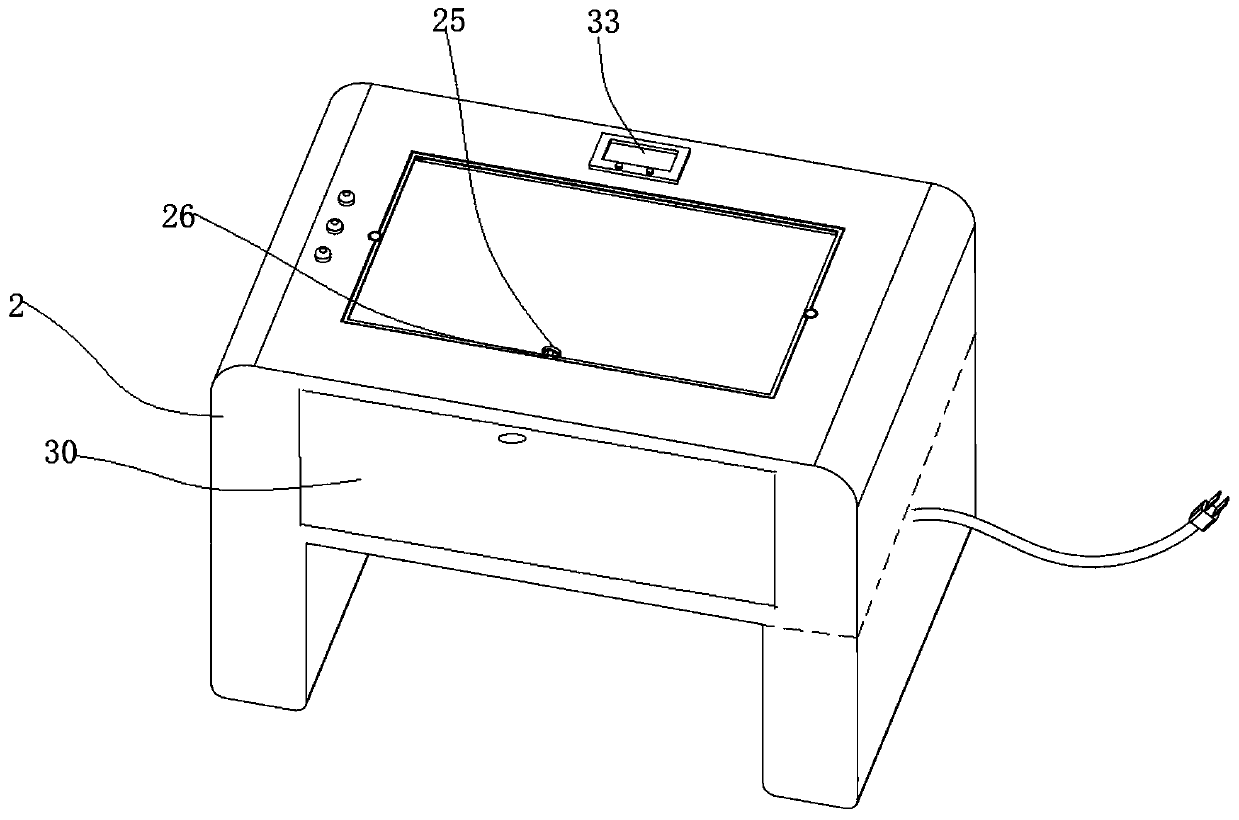

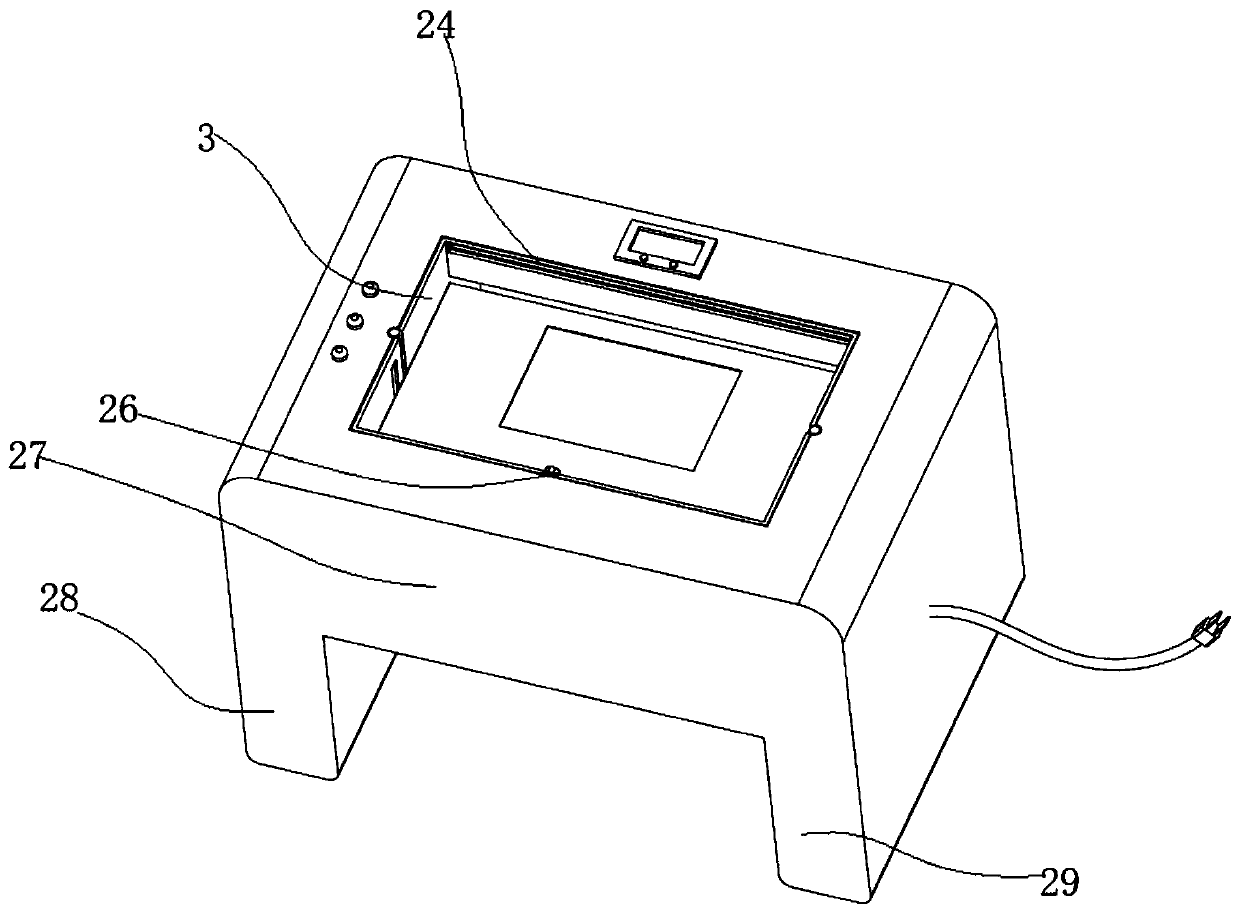

Intelligent hidden computer desk

InactiveCN109730447ABring convenienceSimple, intelligent and convenient operationOffice tablesFeetControl systemControl engineering

The invention discloses an intelligent hidden computer desk comprising a control system, a desk body, a cleaning and holding tank, a first cleaning brush, a second cleaning brush, a desktop and a cover plate; the upper end surface of the desk body is provided with an operation chamber, and the cleaning and holding tank is arranged in the operation chamber; the control system comprises a first control motor, a first control lead screw, a second control motor, a second control lead screw, a rotation control motor and a rotation control shaft; the desktop is arranged and can move up and down in the cleaning and holding tank under the actions of the first control motor and the second control motor; and the cover plate is arranged and covers the upper end surface of the operation chamber, and therefore, the desktop can be hidden into the cleaning and holding tank; and convenience is brought for the user, and the intelligent hidden computer desk is simple, intelligent and convenient to operate.

Owner:周霖

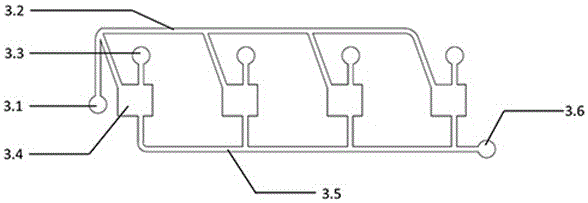

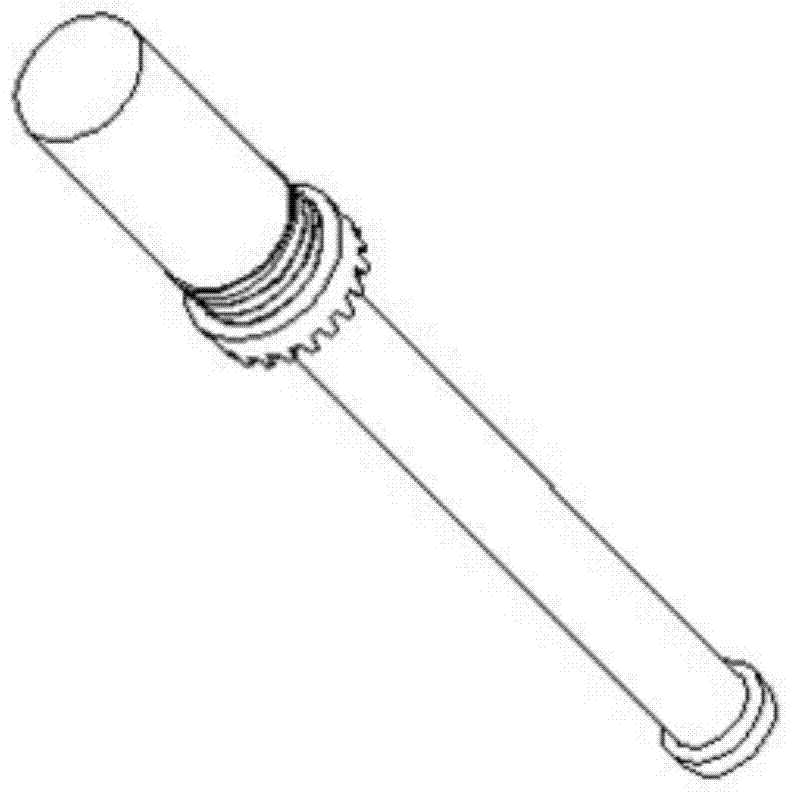

Injection pen

ActiveCN104474609AExhaust accurateEasy injectionInfusion syringesIntravenous devicesEngineeringScrew thread

Owner:JIANGSU DELFU MEDICAL DEVICES CO LTD

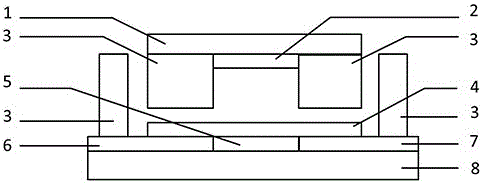

Immunodetection chip, device and system and preparation method of immunodetection chip

InactiveCN106338603AReduce volumeBring convenienceChemiluminescene/bioluminescenceMicrofluidicsEngineering

The invention provides an immunodetection chip, device and system and a preparation method of the immunodetection chip. An organic boom phototransistor is adopted in the immunodetection chip, and the immunodetection chip comprises a phototransistor, an antibody-coated backboard and a microfluidic module integrated between the organic phototransistor and the antibody-coated backboard, wherein the antibody-coated backboard comprises a backboard body, electrodes arranged on the backboard body and antibodies arranged on the electrodes, an organic phototransistor is adopted as the phototransistor, and the microfluidic module is used for completing the immunodetection process. Detection at the bedside of a patient or at home of the patient can be achieved, a professional clinical examiner is not needed for examination, an examination and analysis result can be quickly obtained on the site immediately, and complex treatment and analysis in a specialized laboratory are not needed.

Owner:SHENZHEN UNIV

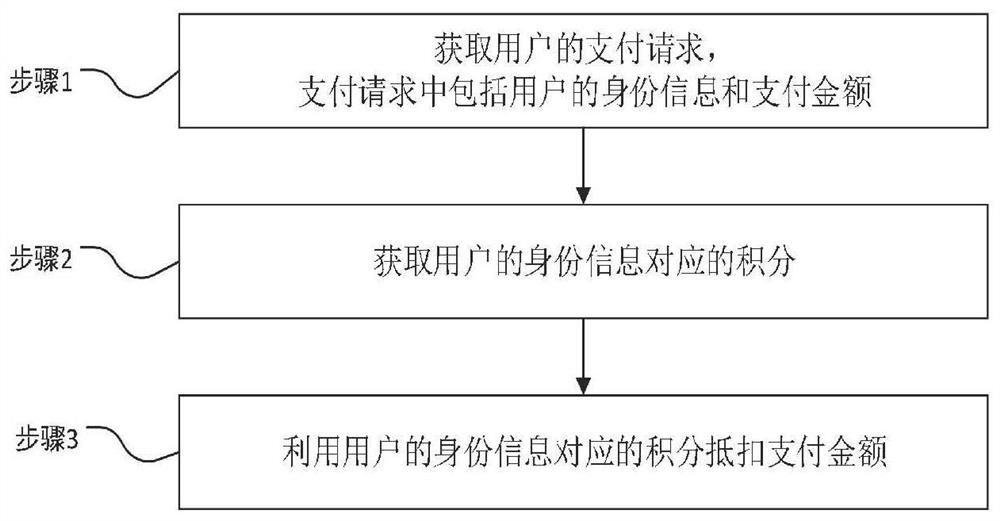

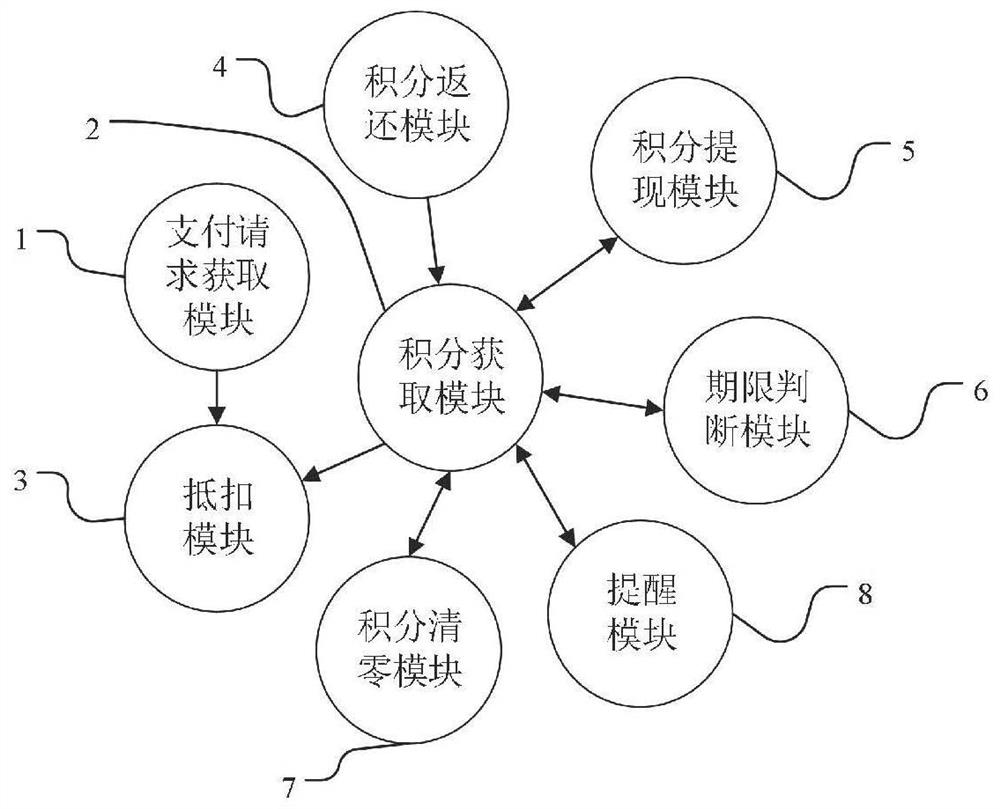

Point payment method and payment system

PendingCN113627965AIncrease desire to buySave time and costDiscounts/incentivesDrug and medicationsComputer securityMedical equipment

The invention discloses a point payment method and payment system, and the method comprises the steps: obtaining a payment request of a user, and the payment request comprises the identity information of the user and the payment amount; obtaining points corresponding to the identity information of the user, wherein the points are discount points and / or labor points, wherein, the discount points are obtained according to the consumption amount of the user, and the labor points are obtained according to the types and times of commodities successfully recommended by the user; and deducting the payment amount by using the points corresponding to the identity information of the user. The invention also correspondingly discloses a point payment system. According to the point payment method and payment system, the user can directly use the points to deduct the payment amount, so that discounts are obtained, and the desire of the user to purchase medicines online through mobile medical equipment is improved.

Owner:四川智慧社区医疗健康科技有限公司

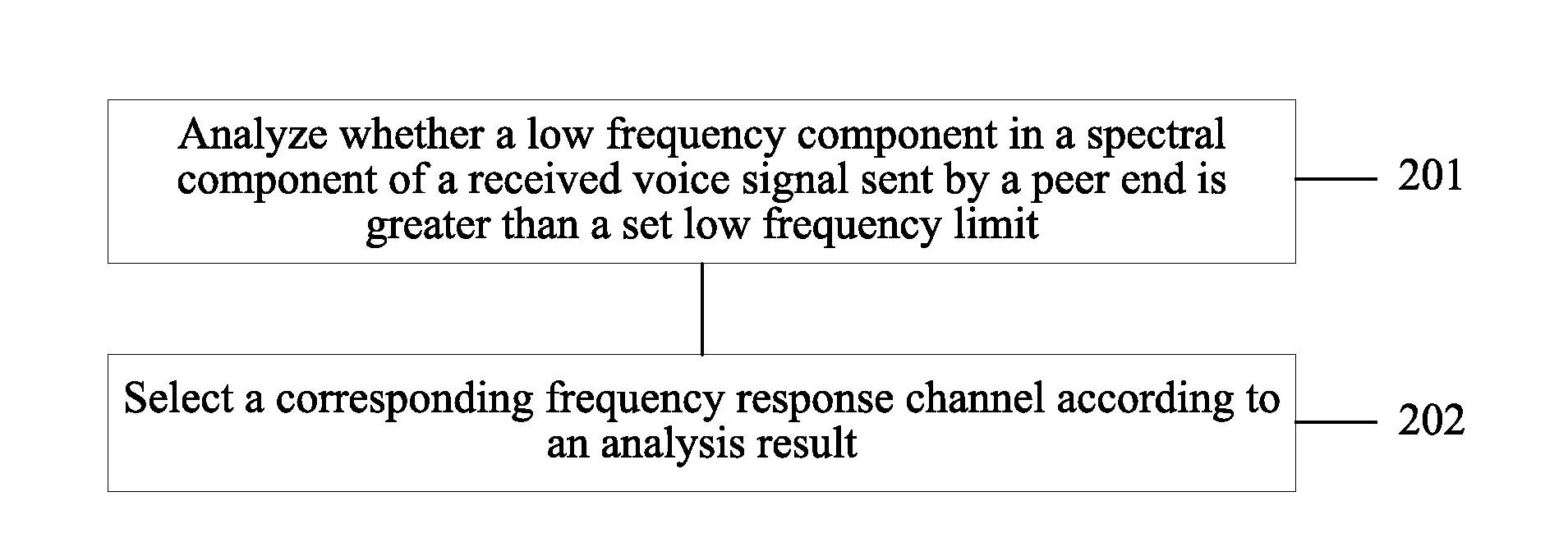

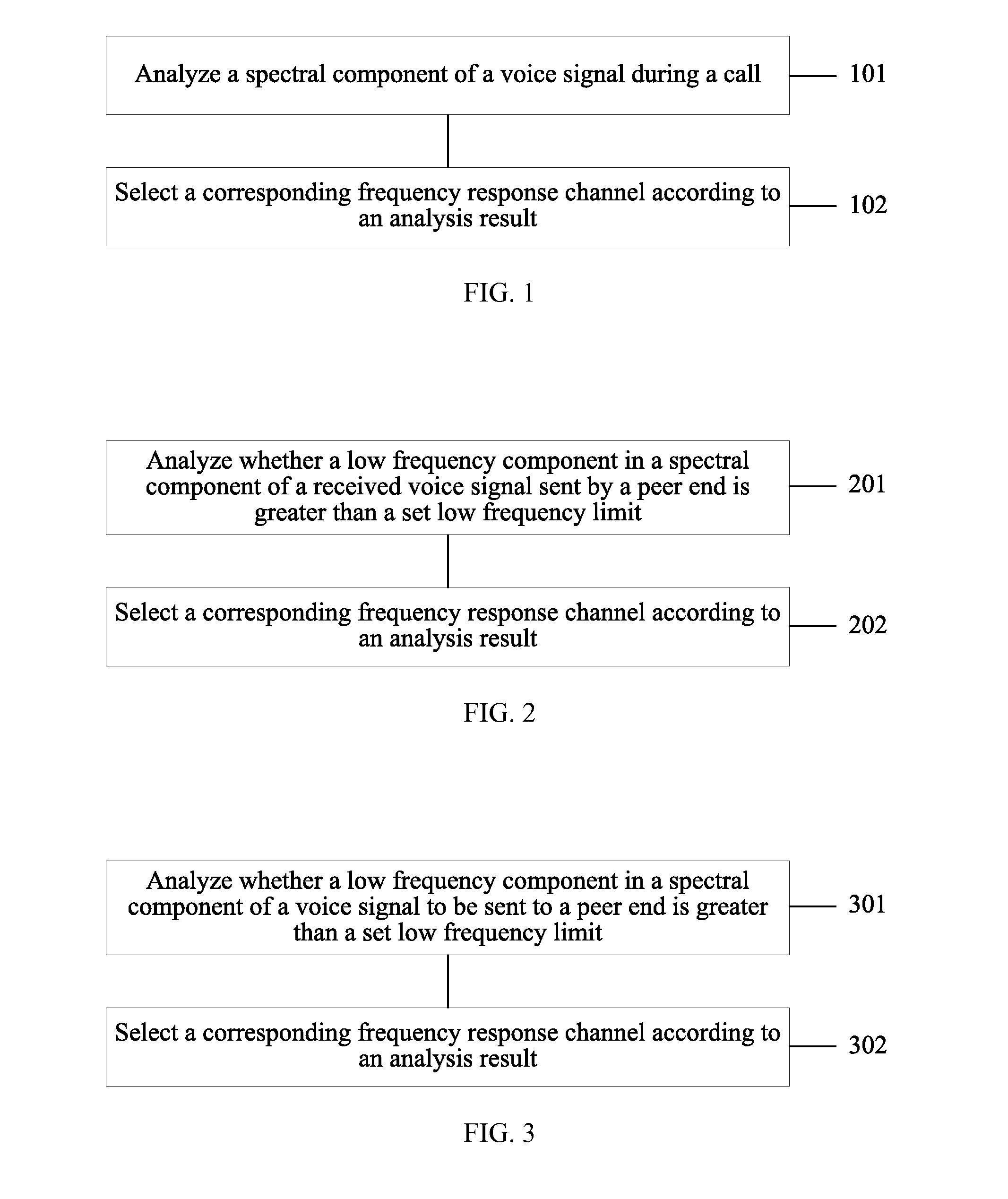

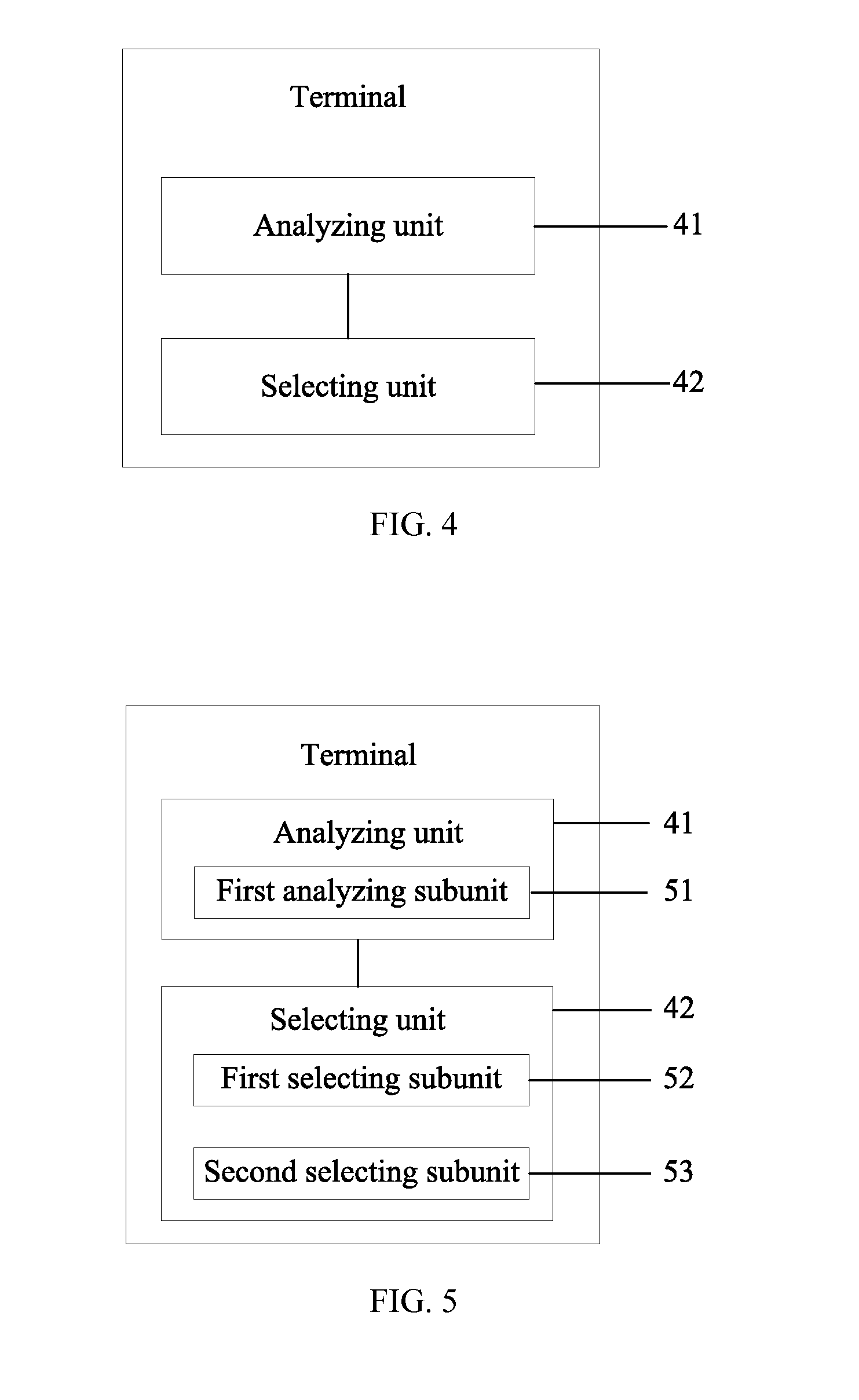

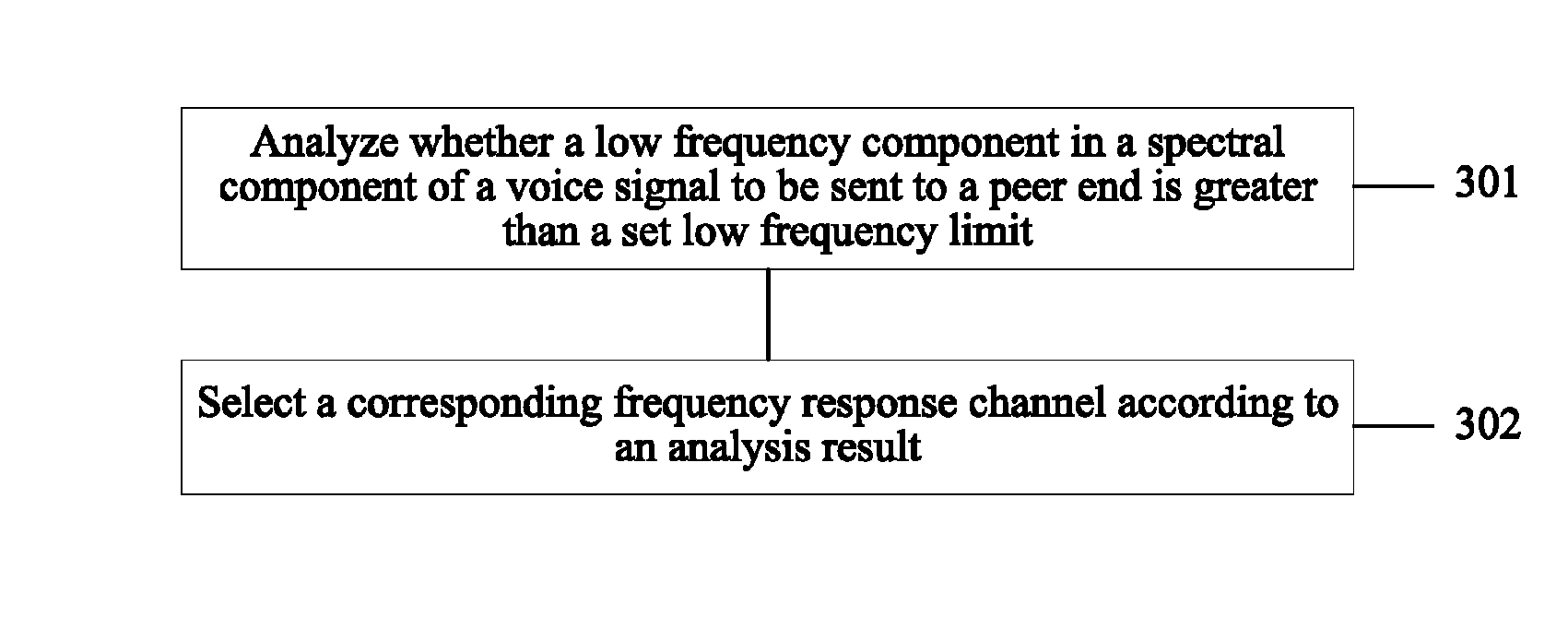

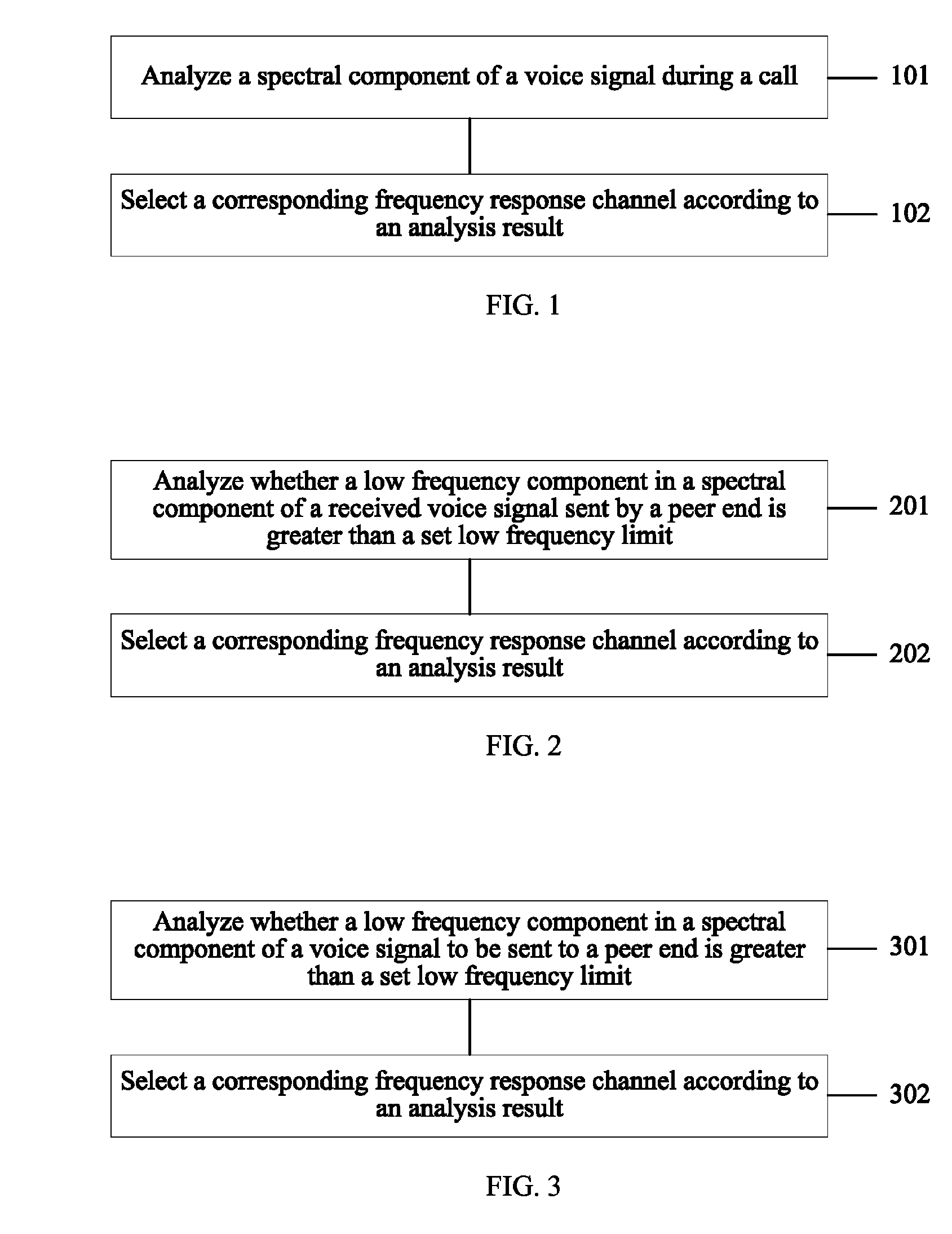

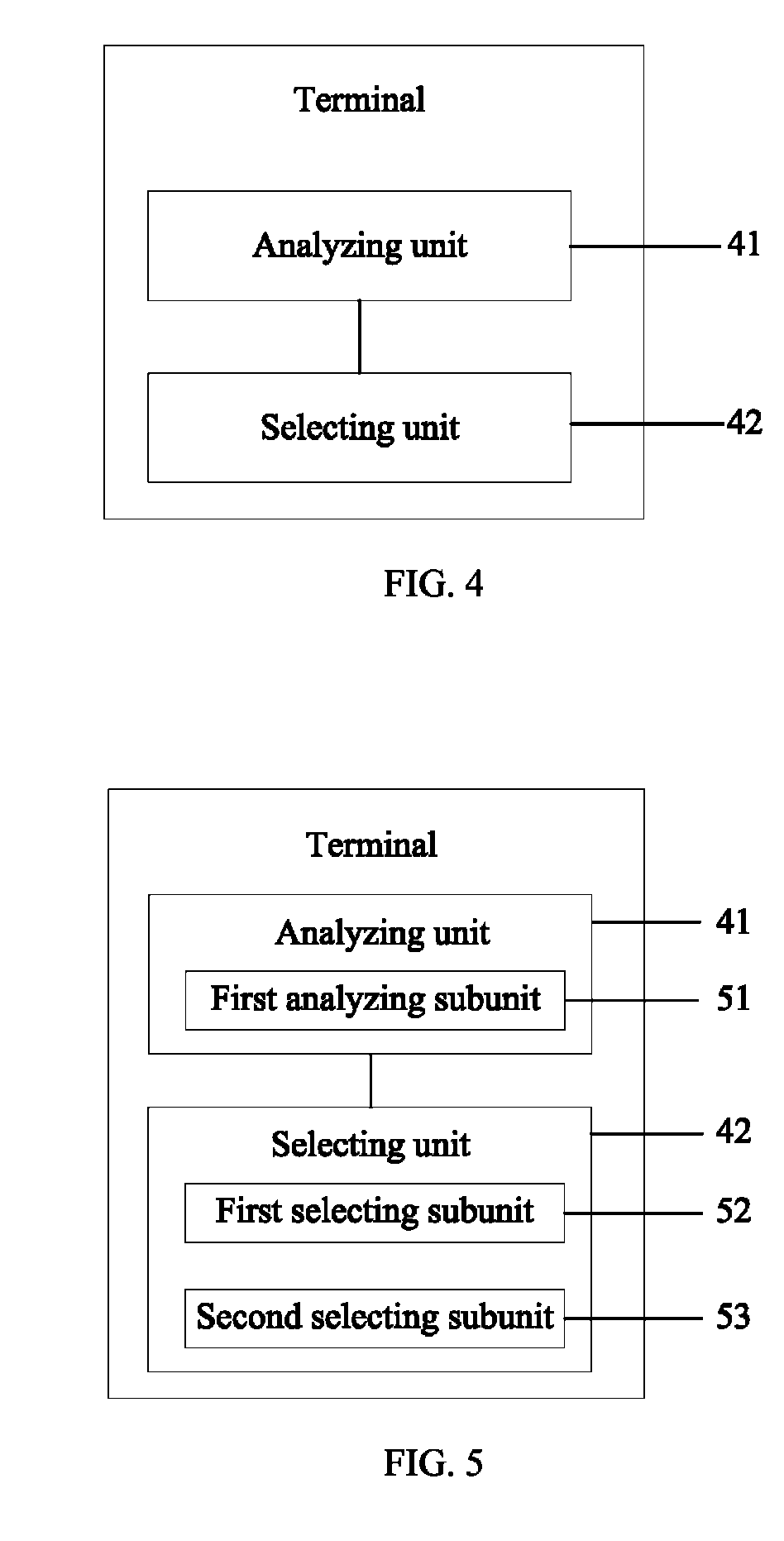

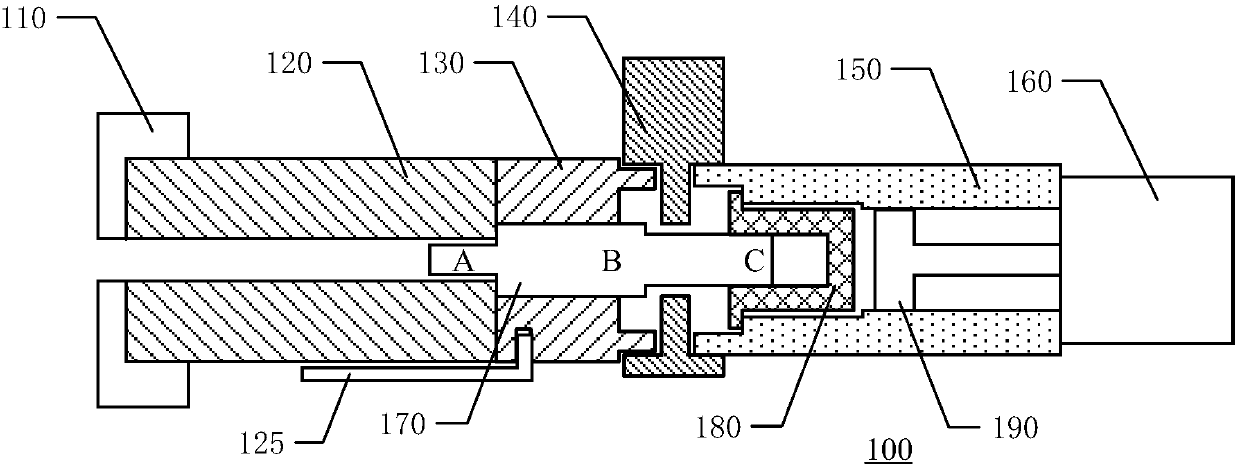

Call Method of Terminal and Terminal Using Call Method

ActiveUS20140051420A1Improve call qualityAvoid problemsSpeech analysisSubstation equipmentTelecommunicationsFrequency spectrum

A call method of a terminal and a terminal using the call method, are provided to adjust voice quality of a call in real time. The method includes analyzing a spectral component of a voice signal during a call and selecting a corresponding frequency response channel according to an analysis result of the spectral component of the voice signal.

Owner:HUAWEI DEVICE CO LTD

Functional mode switching method for providing different group use in cell phone

ActiveCN101005525BBring convenienceTelephone sets with user guidance/featuresHuman–computer interactionGroup setting

Owner:INVENTEC(NANJING) TECH CO LTD

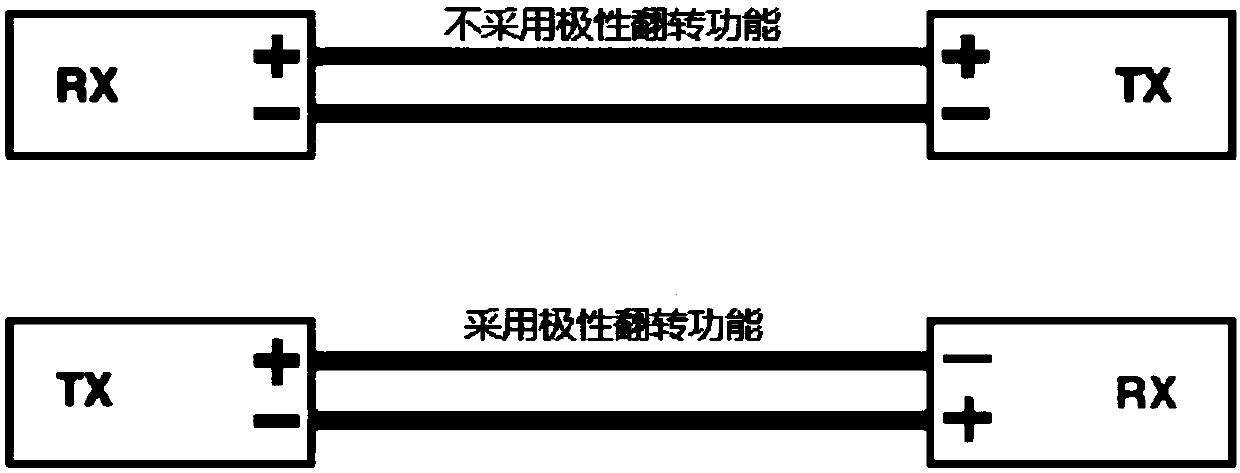

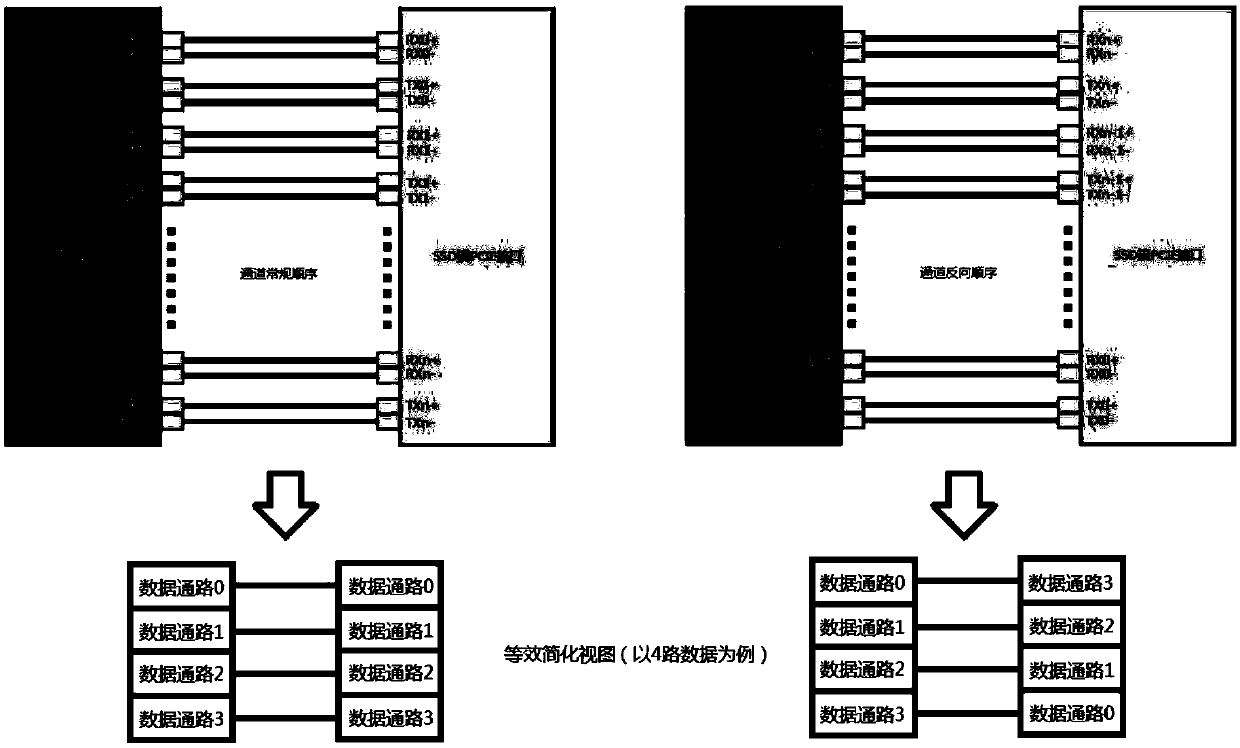

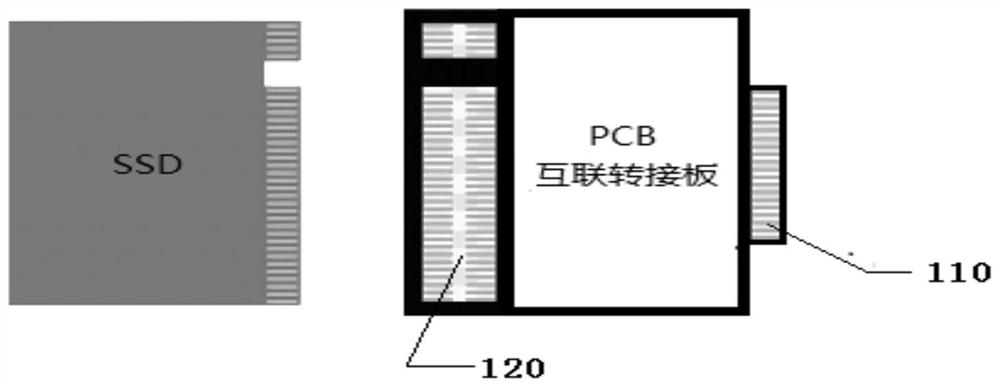

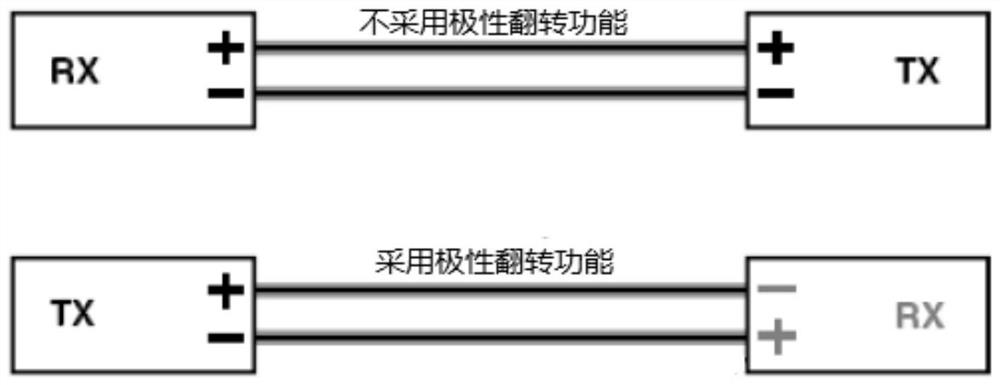

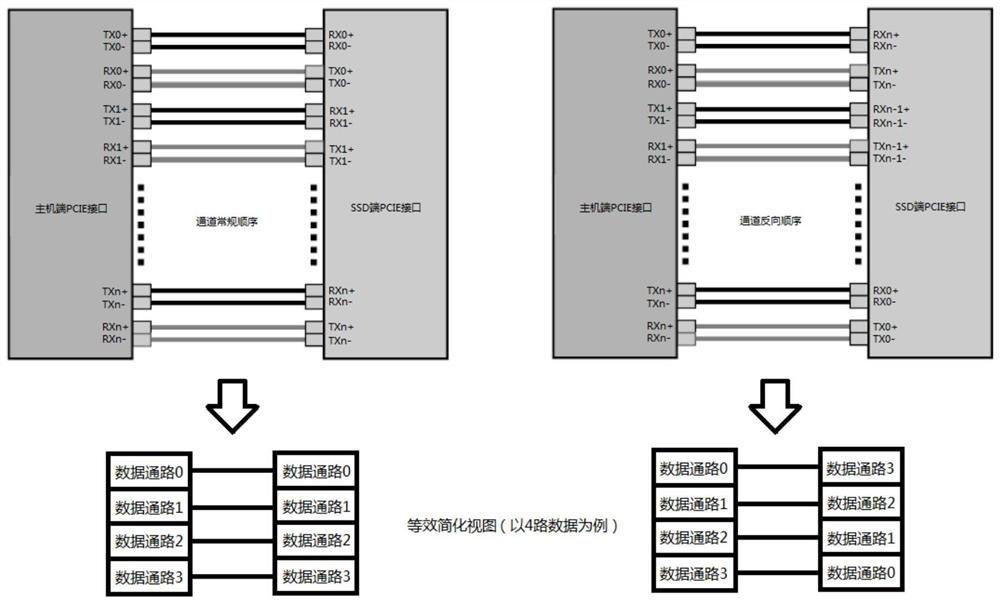

Pcie interface, connector and terminal device

InactiveCN109565124ARealize transmissionBring convenienceCoupling contact membersComputer periphery connectorsTerminal equipmentComputer terminal

A PCIE interface, a connector, and a terminal device, the PCIE interface comprising: at least one pair of ports, which have a receiving function attribute and are used for receiving data; and at leastone pair of ports, which have a transmitting function attribute and are used for transmitting data. Two ports of each pair of ports have opposite polarities, and each of the ports having the receiving function attribute and the transmitting function attribute has the same attribute as a port in central symmetry with the port. The interface can realize normal data transmission when inserted in both forward and reverse directions.

Owner:SZ DJI TECH CO LTD

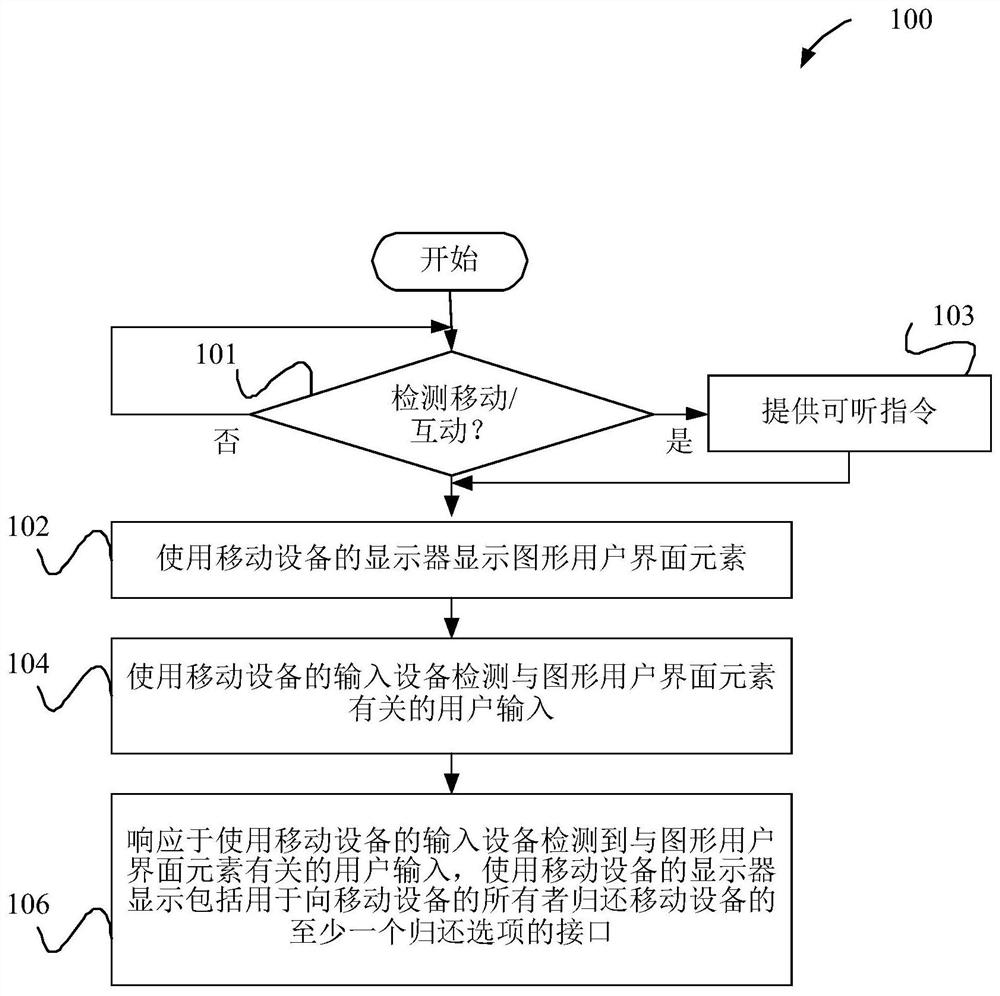

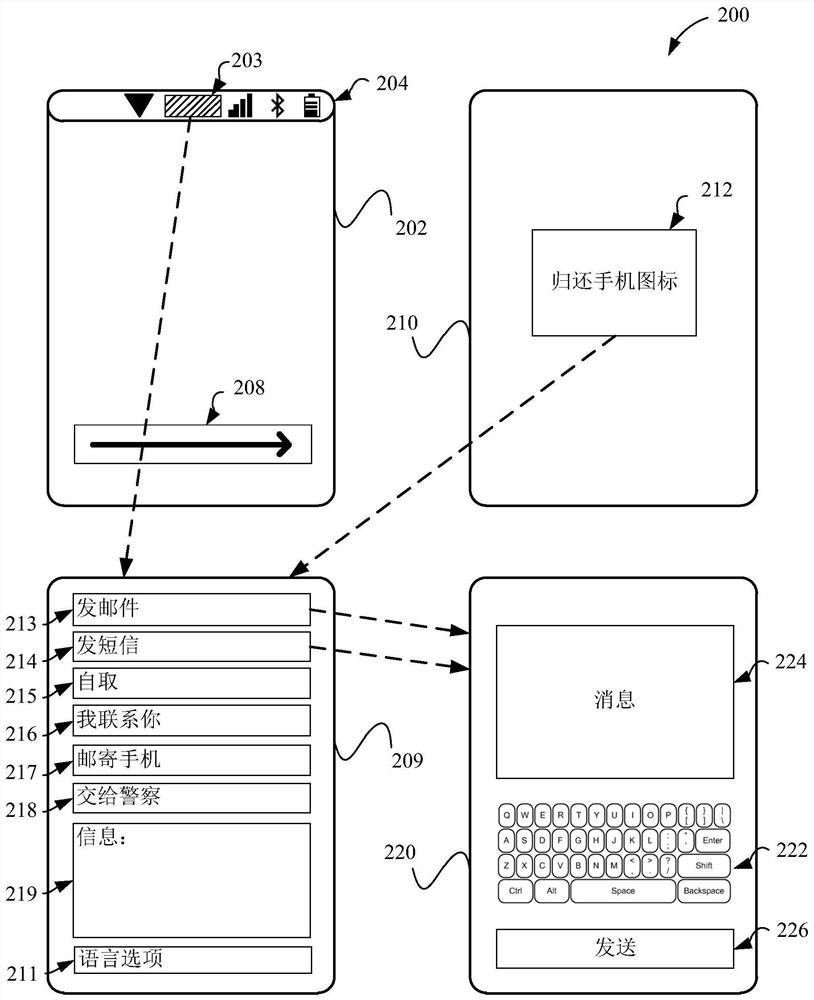

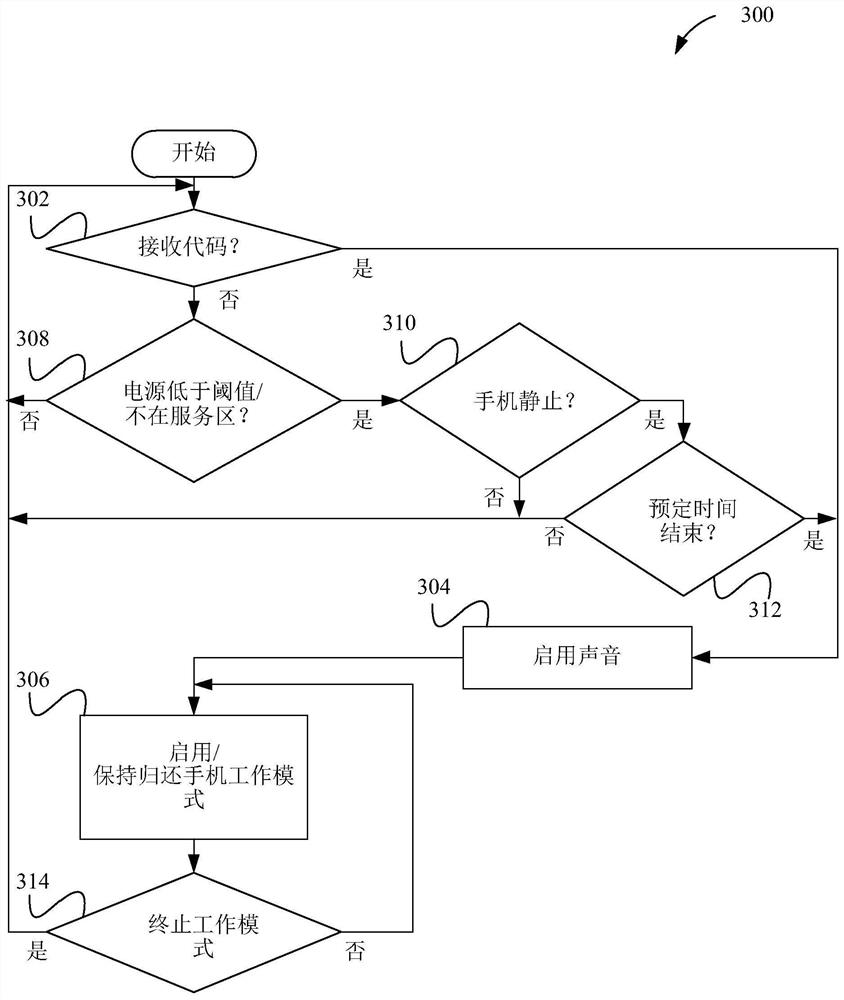

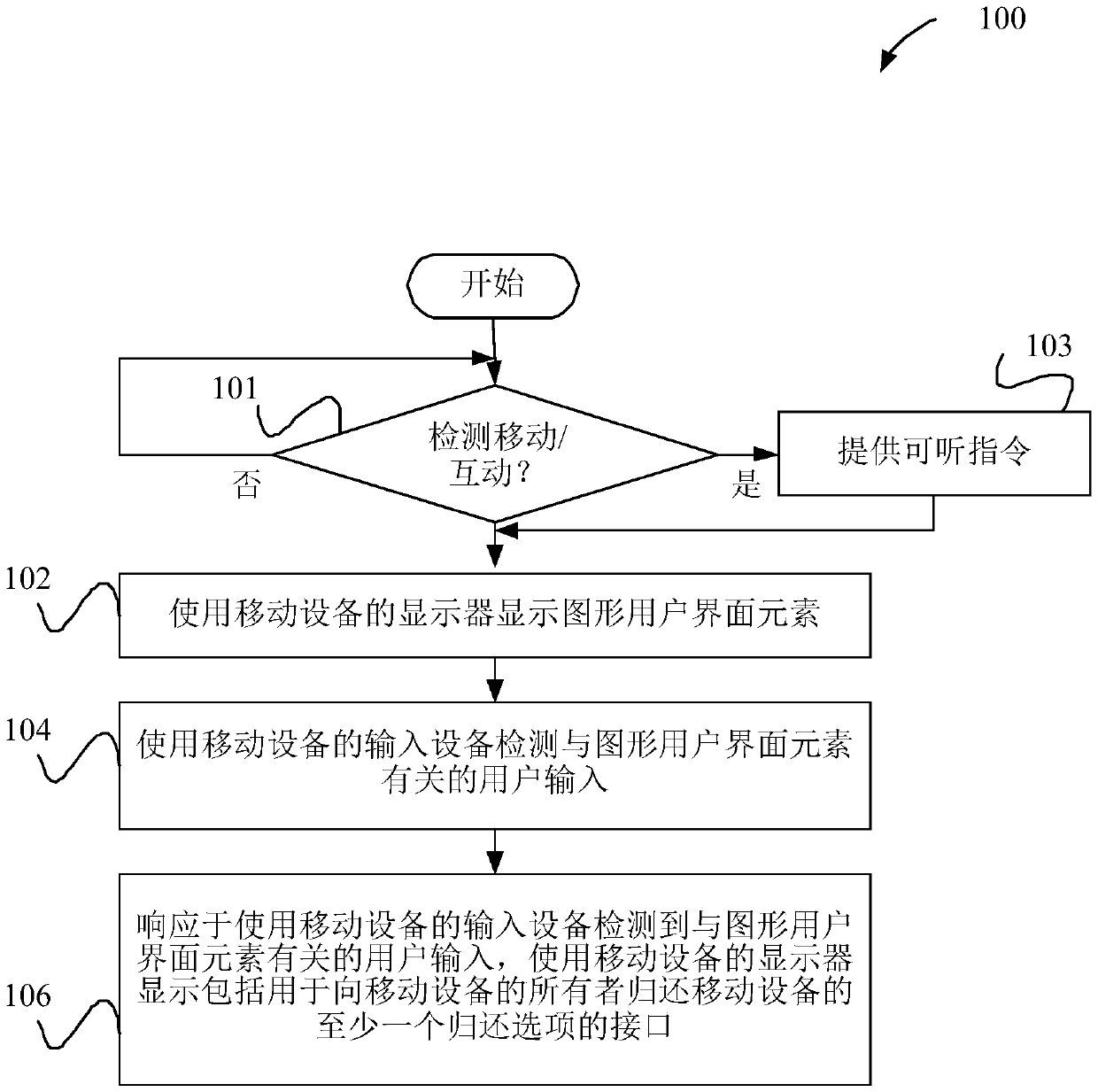

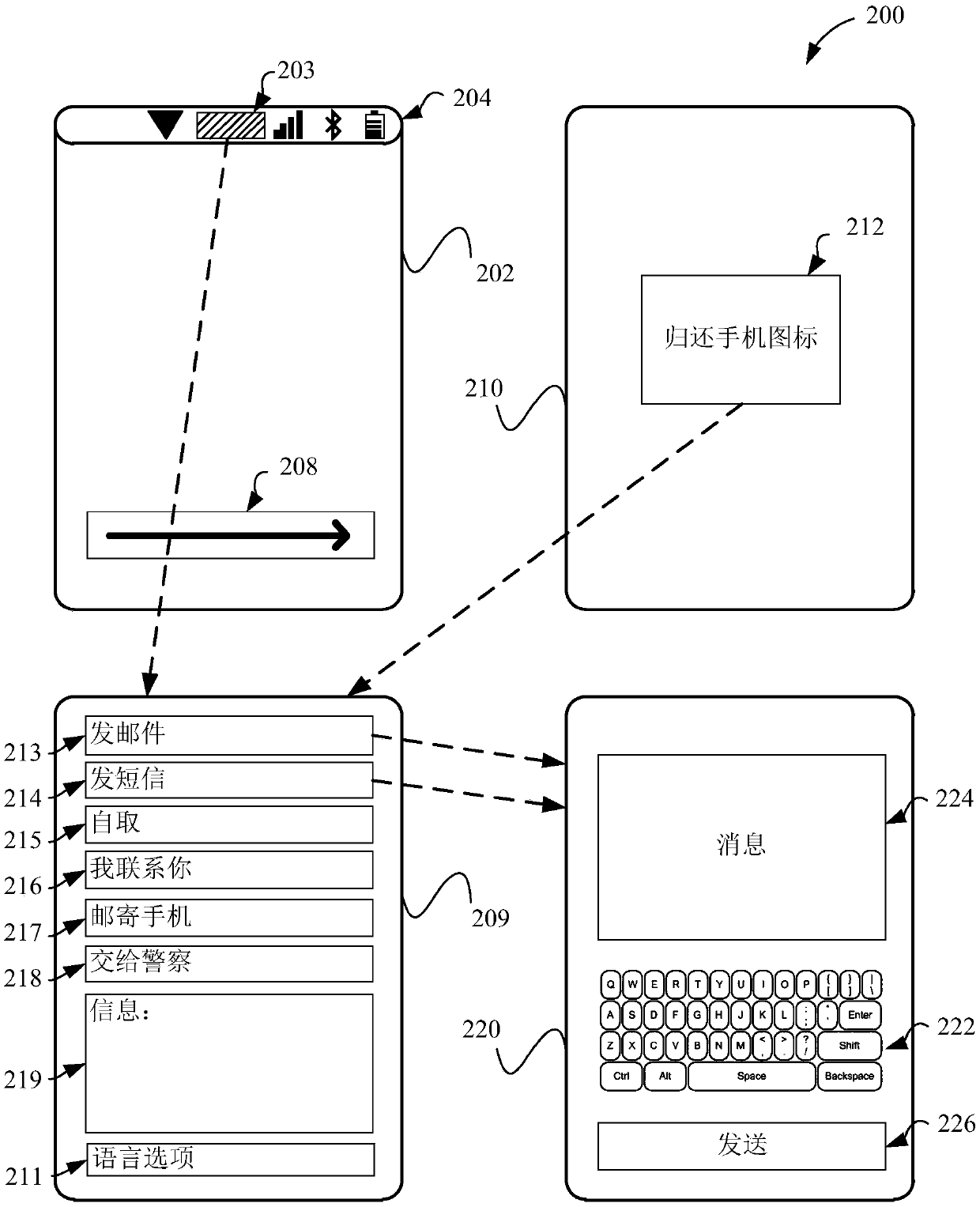

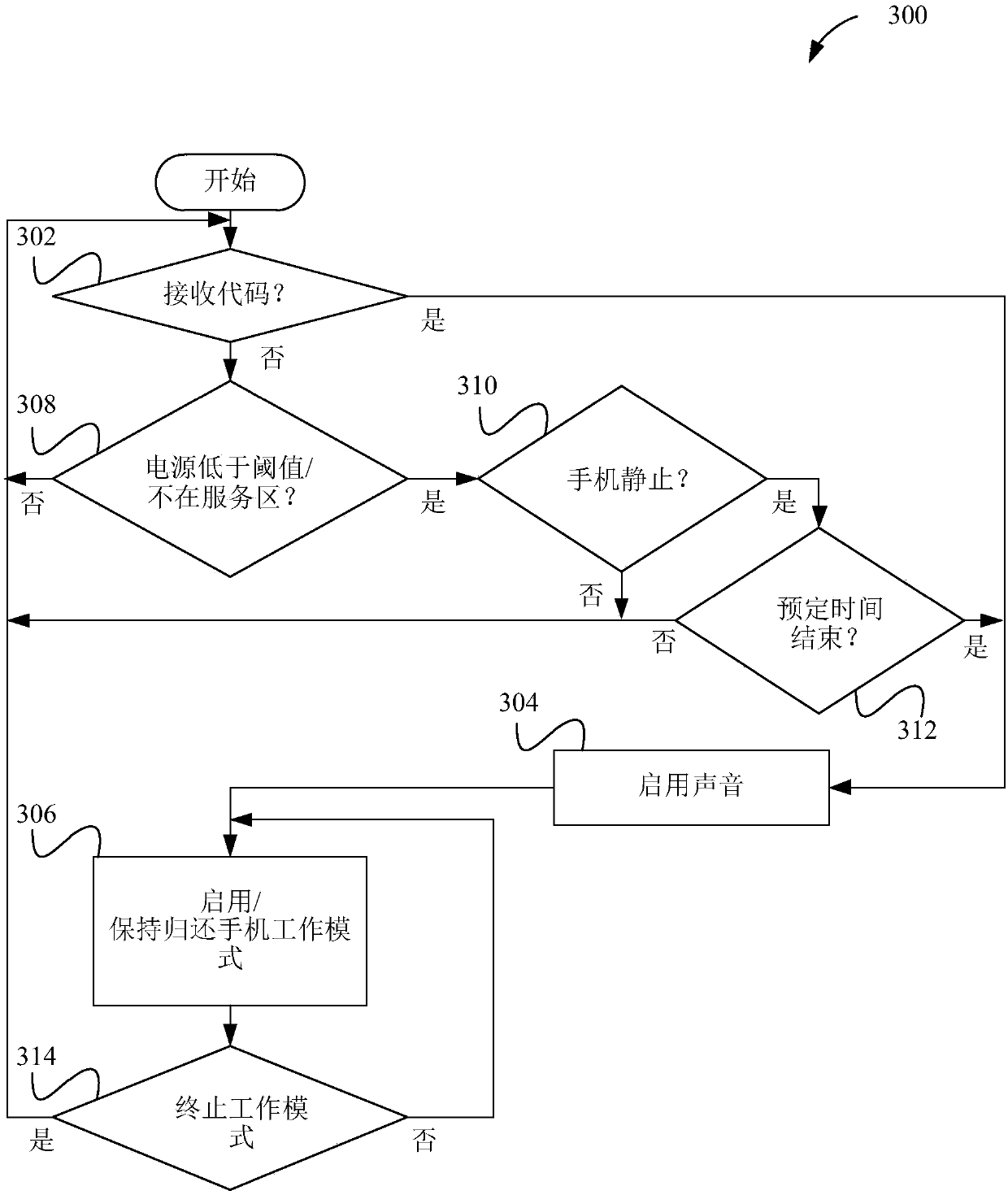

Apparatus and method for facilitating the return of a mobile device

ActiveCN109644319BEasy to returnPrecise positioningPower managementParticular environment based servicesGraphical user interfaceDisplay device

An apparatus and method are provided to facilitate the return of a mobile device to an owner. Graphical user interface elements are displayed using the display of the mobile device. User input related to the graphical user interface element is detected using an input device of the mobile device. An interface including at least one return option for returning the mobile device to an owner of the mobile device is displayed using a display of the mobile device. Such an interface is displayed in response to detecting user input related to a graphical user interface element using an input device of the mobile device.

Owner:HUAWEI TECH CO LTD

an injection pen

ActiveCN104474609BExhaust accurateEasy injectionInfusion syringesIntravenous devicesEngineeringScrew thread

Owner:JIANGSU DELFU MEDICAL DEVICES CO LTD

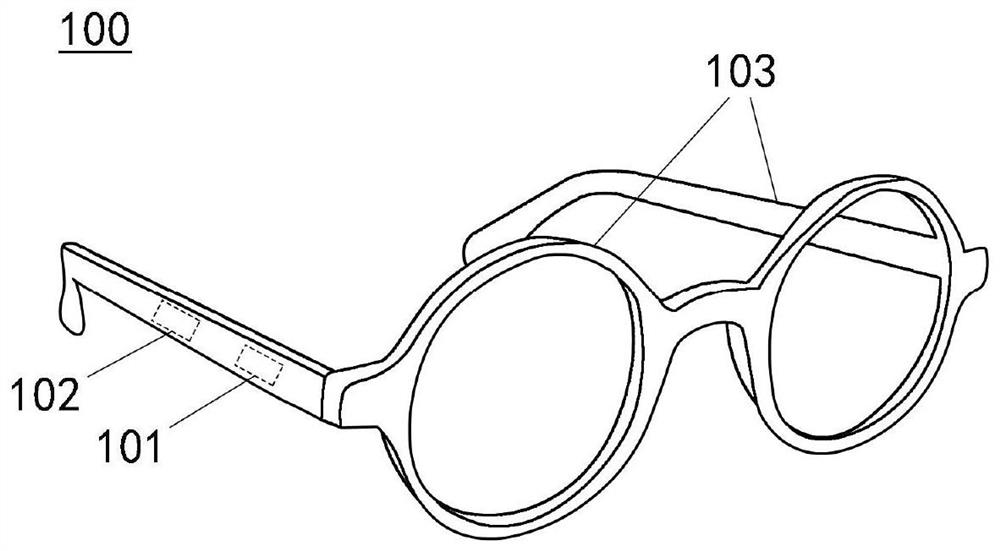

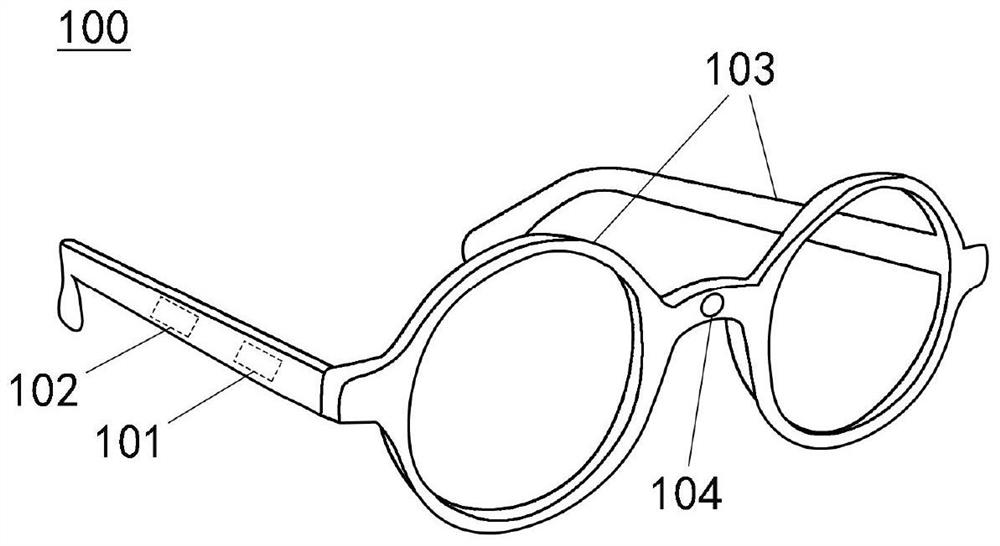

Sports glasses, sports glasses control method and storage medium

ActiveCN111505838BBring convenienceImprove experienceNon-optical adjunctsClosed circuit television systemsSimulationEyewear

The disclosure relates to sports glasses, a control method for the sports glasses, and a storage medium. Among them, the sports glasses include: an identification module, which is used to identify the type of exercise; a transmission module, which is electrically connected to the identification module, obtains the type of exercise identified by the identification module, and sends a notification of recording and analyzing the corresponding exercise data to the preset linkage device according to the exercise type. The sports glasses provided in the present disclosure, based on the recognized sports type, send a notification to the preset linkage device to record and analyze the sports data corresponding to the sports type. Realize that the user does not need to turn on the device to record the corresponding exercise data before performing a certain exercise, but sends a notification to the preset linkage device to record and analyze the exercise data. The preset linkage device records and analyzes motion data based on notifications, which brings convenience to users and enhances user experience.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

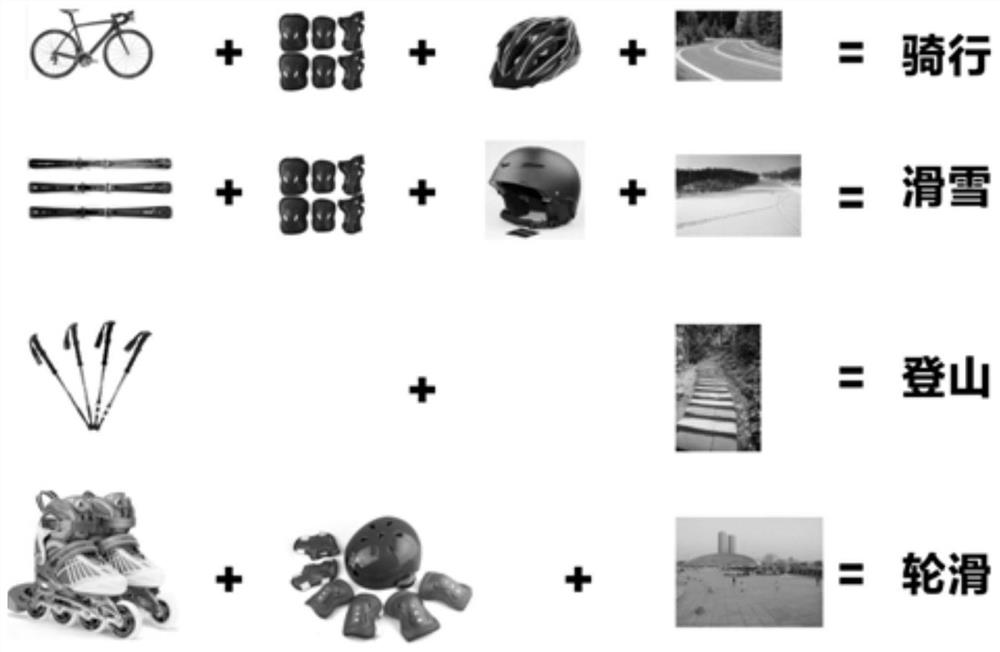

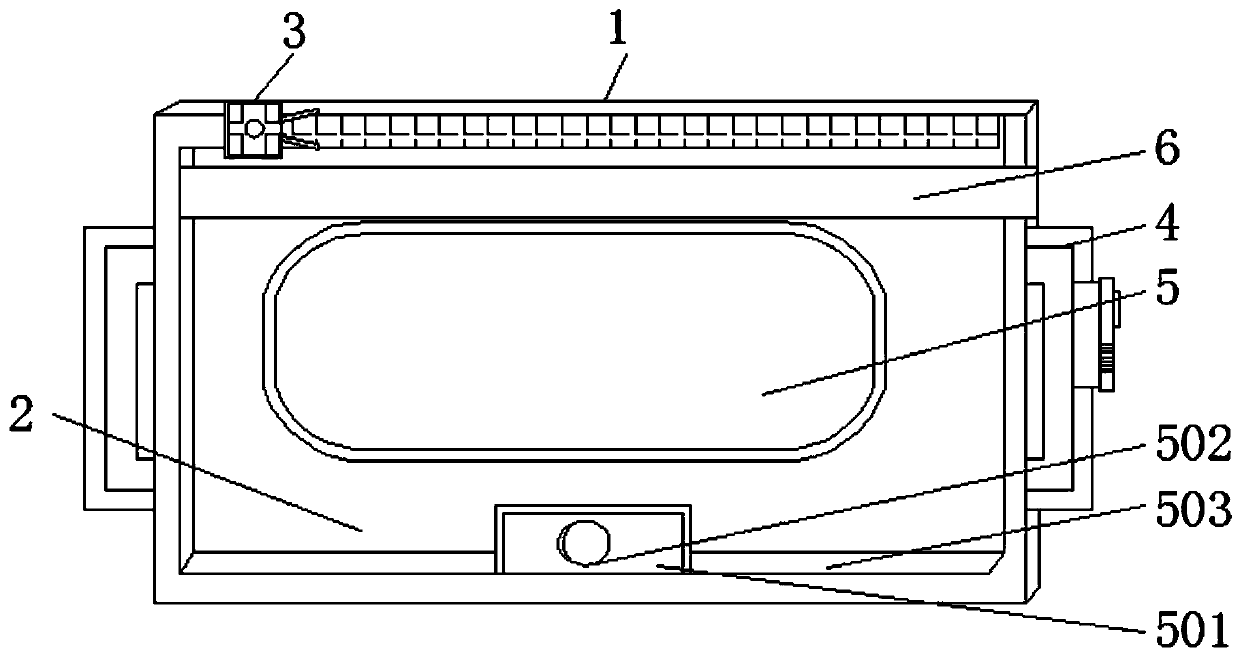

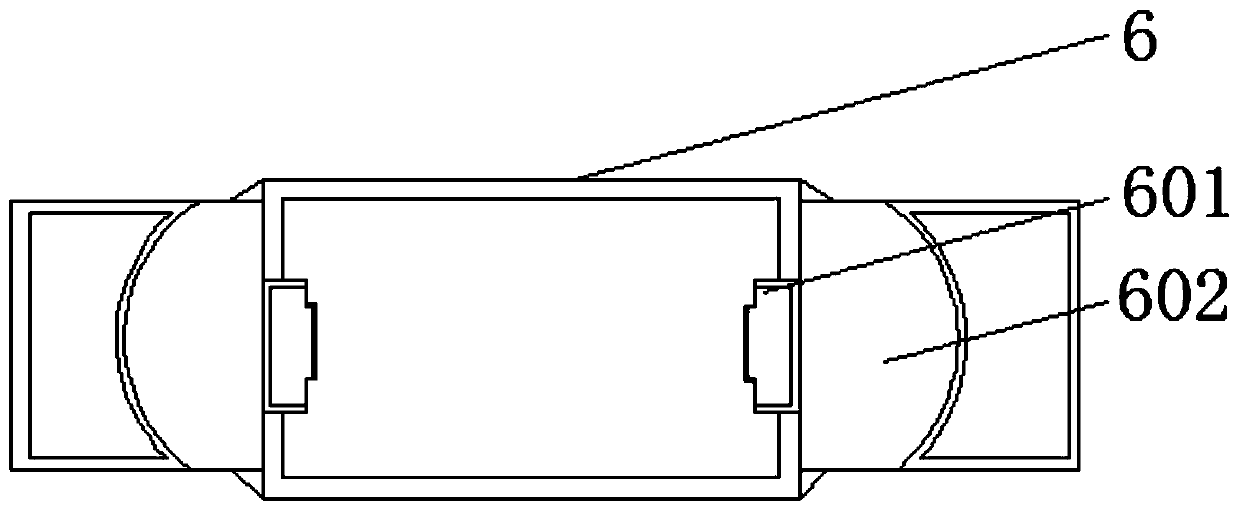

Film scanning device

InactiveCN102075657AReduce the overall heightReduce volumeTelevision system scanning detailsImaging processingEngineering

The invention provides a film scanning device. The film scanning device comprises a shell, a film imbedding seat, a backlight module, an induction module and an image processing module and is characterized by also comprising a mirror surface, wherein the film imbedding seat is arranged in the shell; the backlight module is arranged in the shell for projecting light to a film which is loaded on the film imbedding seat to provide light required for film development; the induction module is arranged corresponding to a first side face in the shell; the image processing module is used for converting an image which is received by the induction module into a digital image; and the mirror surface is arranged on a second side face in the shell for reflecting the light which is projected to the film by the backlight module to the induction module, so that the induction module collects the light which is projected to the film by the backlight module and receives the image stored by the film.

Owner:MUSTEK SYSTEMS

Multi-functional heating bag

PendingCN110934683AGood massageEffective and practicalVibration massageTherapeutic coolingEngineeringMechanical engineering

The invention discloses a multi-functional heating bag. The multi-functional heating bag comprises a main body and two wear resistance strips, wherein an outer bag is arranged outside the main body; azip fastener is mounted at the top end of the outer bag; an inner bag is mounted in the outer bag; an observing window is formed in the middle part of the outer bag; a bracket mechanism is arranged in the outer bag; a connecting wire is connected to the inner wall of a bottom plate; a vibration motor is connected to the inner wall of the connecting wire; and the wear resistance strips are arranged at the upper end and the lower end of the bottom plate. According to the multi-functional heating bag disclosed by the invention, the vibration motor is arranged, so that the hands of a user are convenient to massage, the hands of the user are effectively relieved, convenience is effectively brought to the user, and practicality and convenience are effectively brought to the user; the two symmetrical wear resistance strips are arranged at the rear end of the main body, so that an outer cover at the rear end of the main body is effectively protected, and the situation that the outer cover issubjected to friction to be damaged caused by long-time using is avoided; and the multi-functional heating bag is provided with the bracket mechanism, so that the user can conveniently play a cell phone during warming the hands without delaying playing the cell phone or warming the hands.

Owner:广州慧营智能科技有限公司

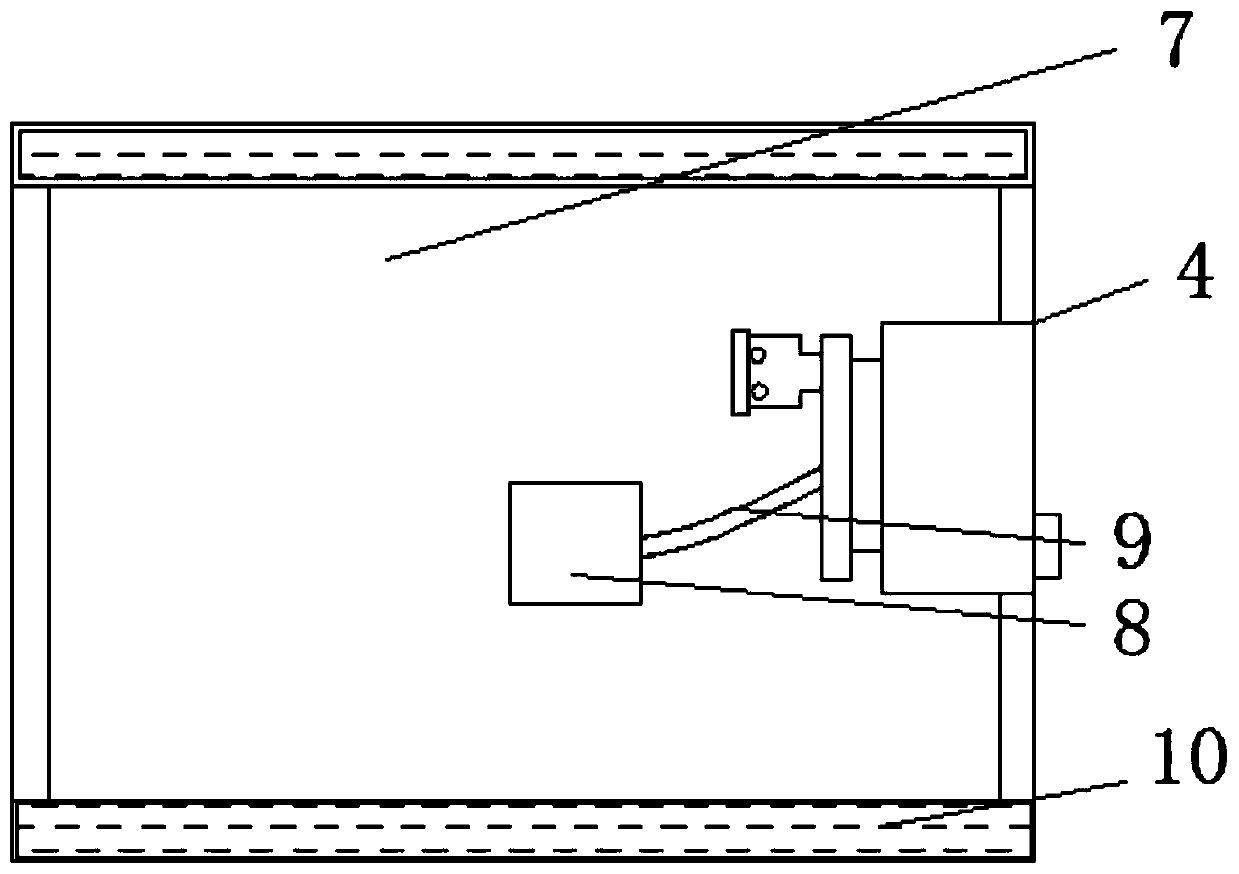

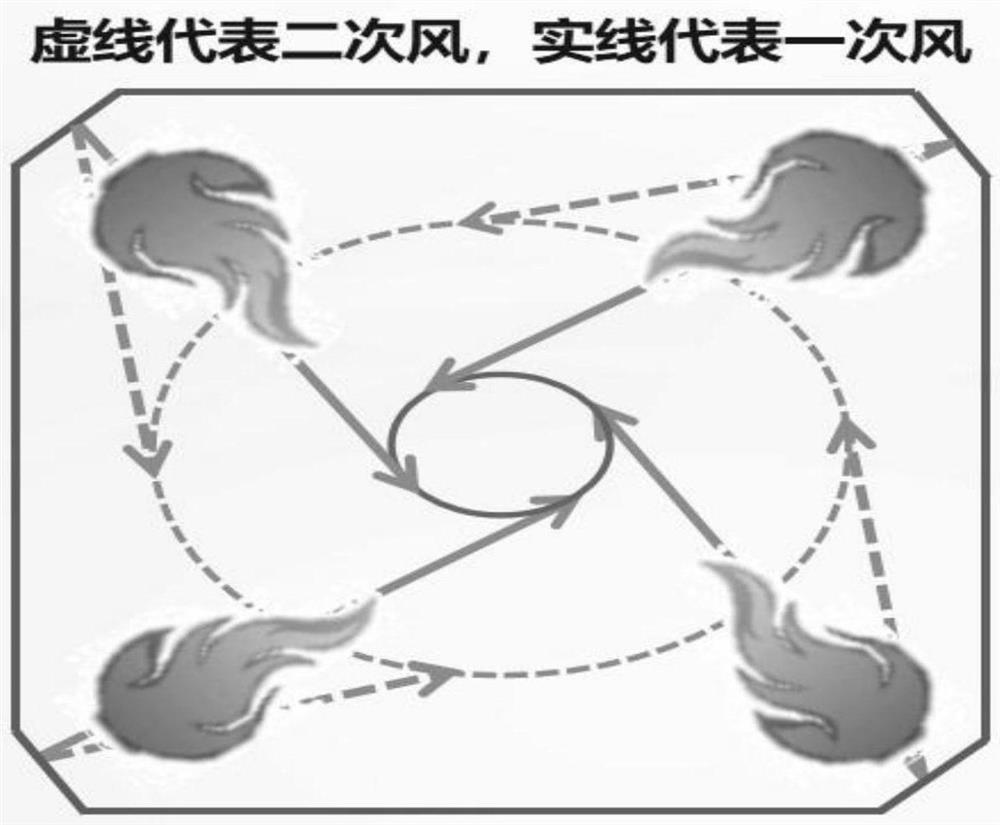

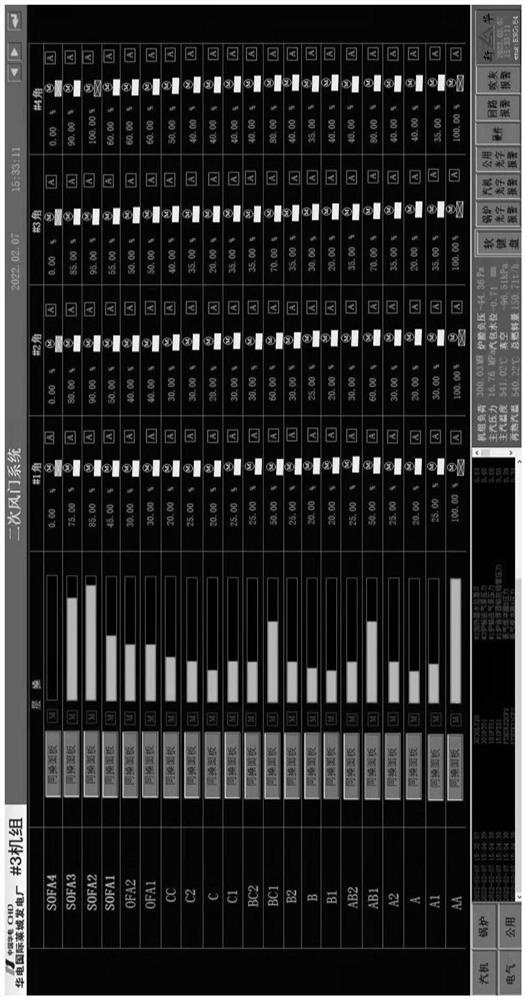

Combustion adjusting method for corner tangential pulverized coal furnace based on 3H air volume control method model

PendingCN114674009AStable combustionStable flue gas temperature fieldAir supply regulationCasings/liningsAir volumeCombustion

The invention discloses a four-corner tangential pulverized coal furnace combustion adjusting method based on a 3H air volume control method model, and relates to the technical field of thermal power generation. According to the method, five models including a coal quality coefficient model, an aerodynamic model, an ignition dynamic model, a flue gas temperature model and a parameter comparison model are established, and a coal quality parameter model serves as a basis, and the aerodynamic model serves as a basic framework; a flue gas temperature model, an ignition state model and a parameter comparison model are used as actual references for correction, different grading air distribution of the same-angle vertical face, the same-layer cross section and the same-boiler three-dimensional face is achieved, the concept of a 3H air volume control method is put forward based on combustion adjustment, stable combustion in the boiler is achieved through air distribution adjustment, and the combustion efficiency is improved. And a stable flue gas temperature field and an aerodynamic field are formed.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

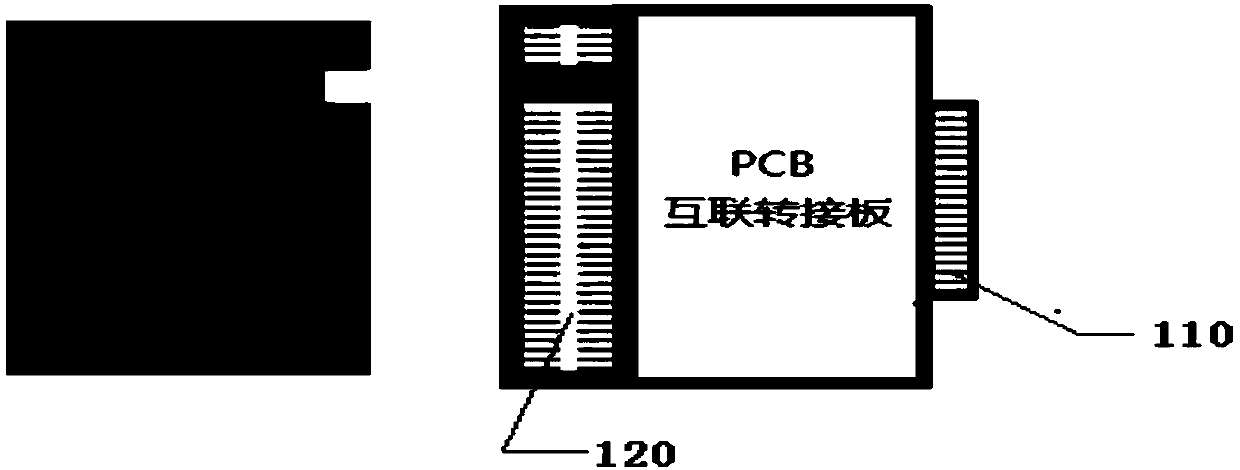

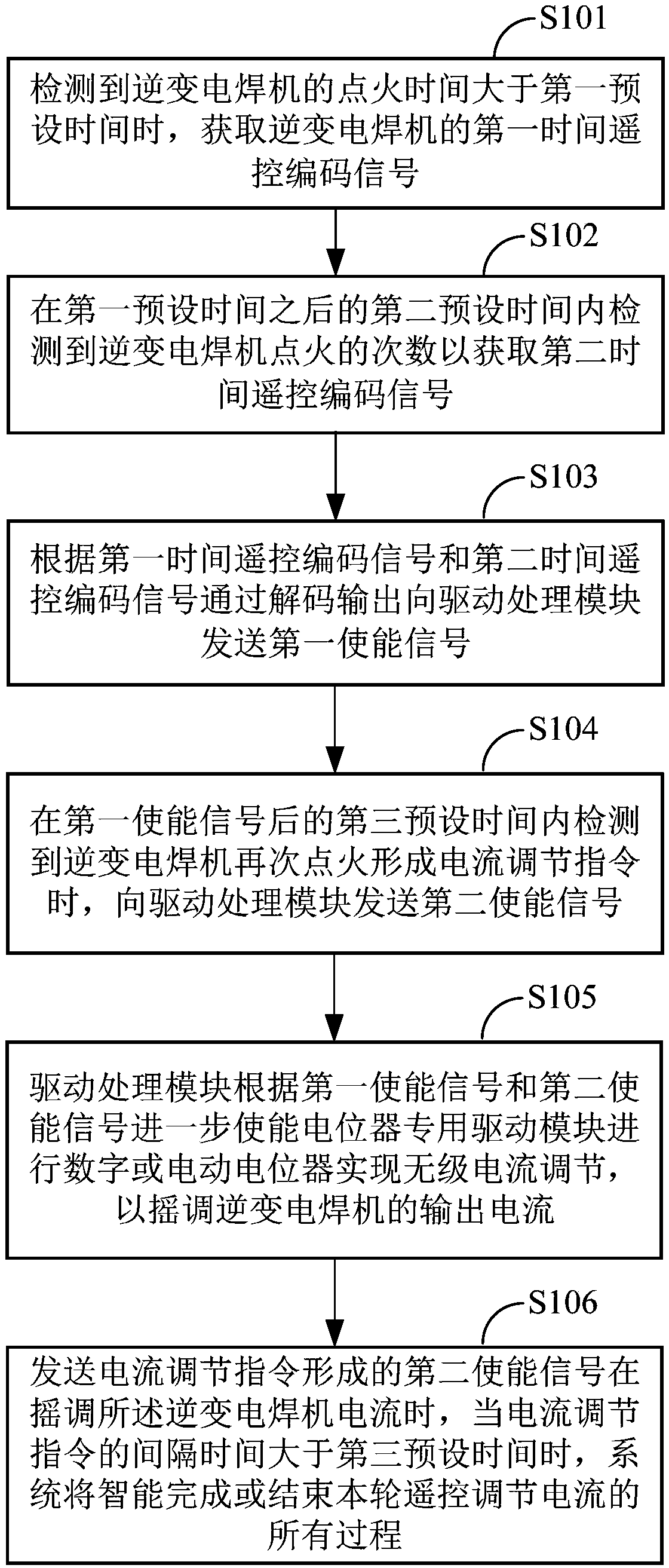

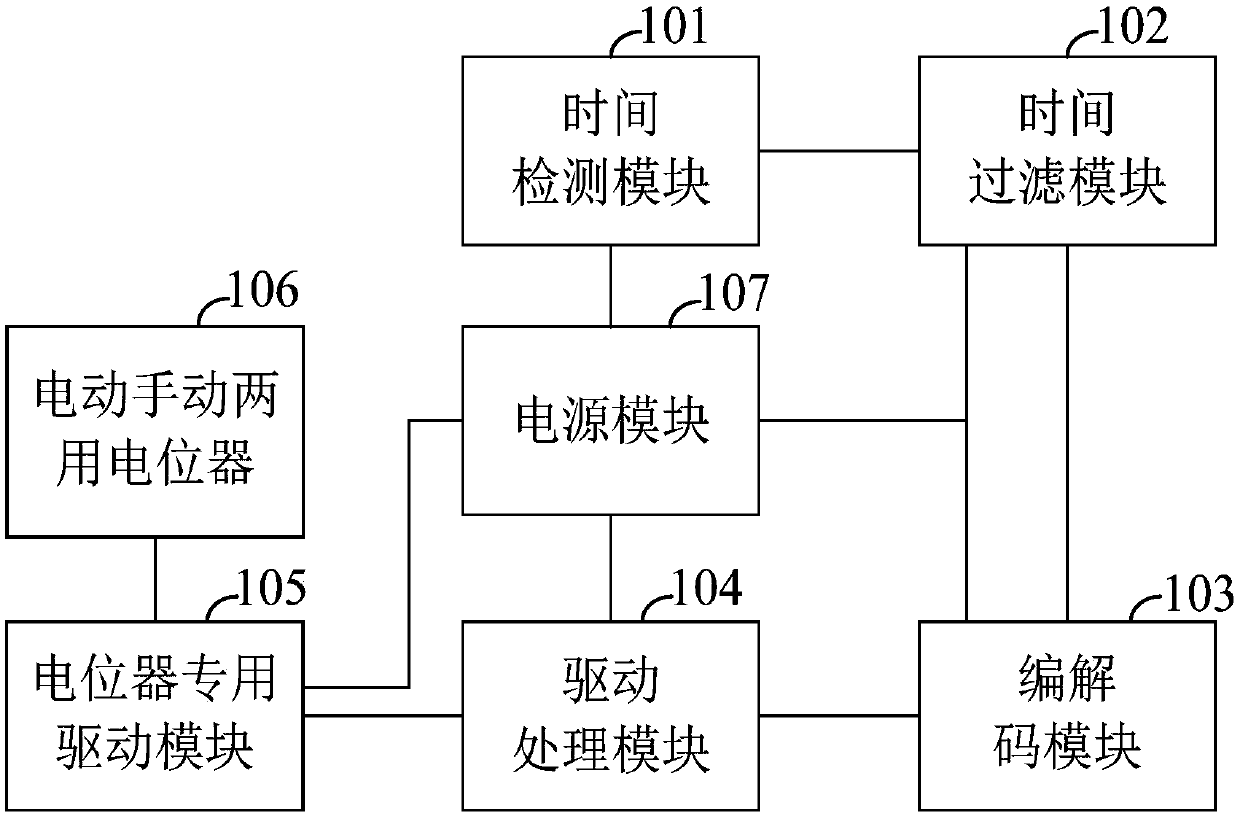

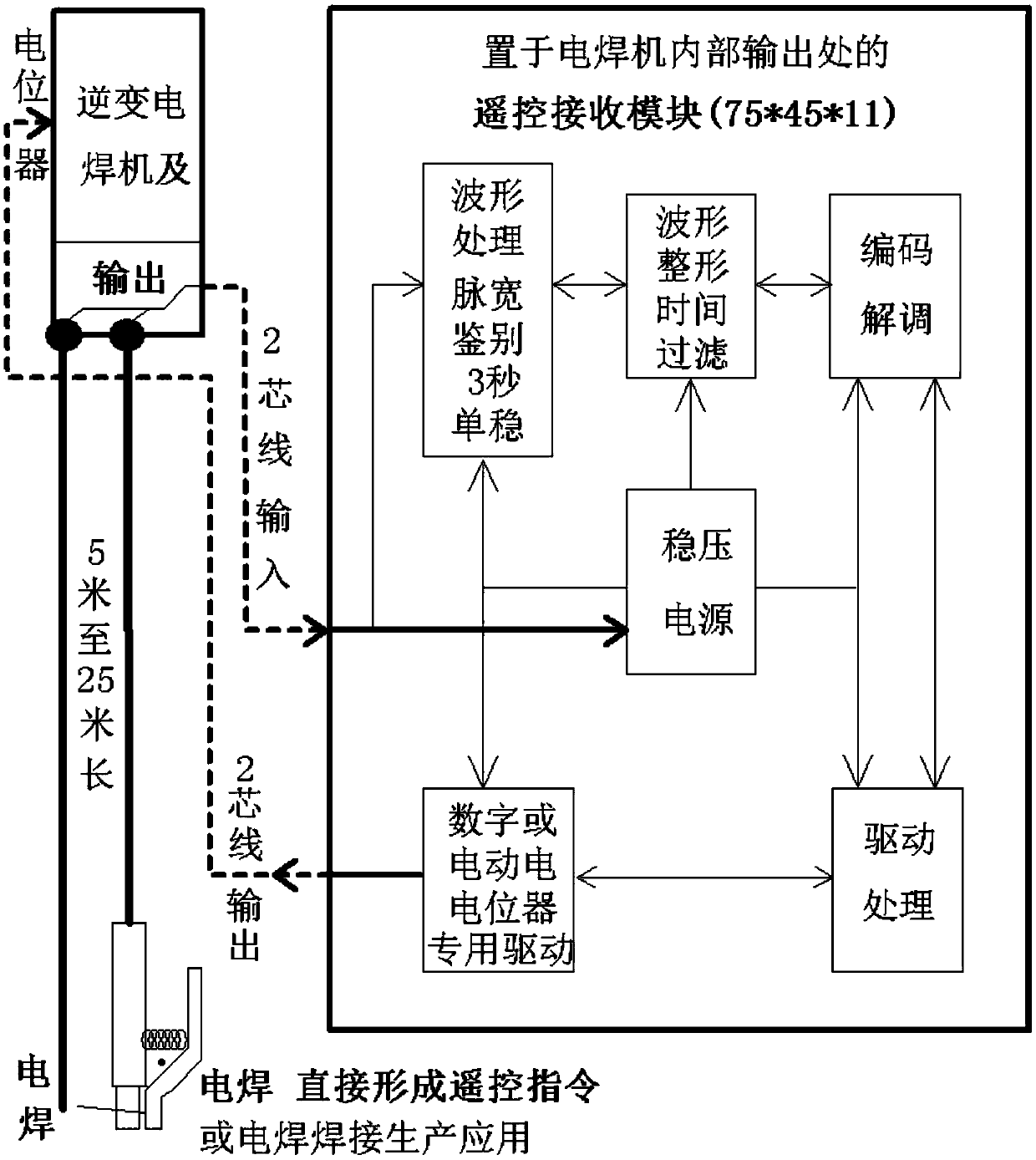

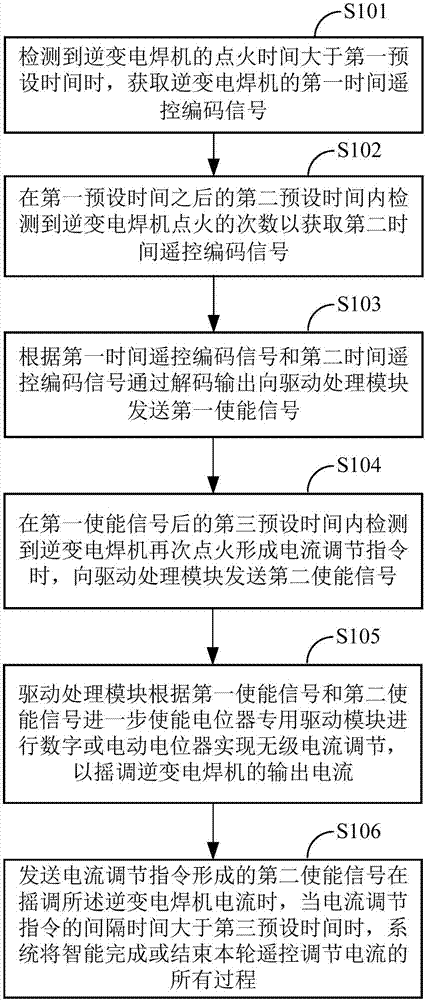

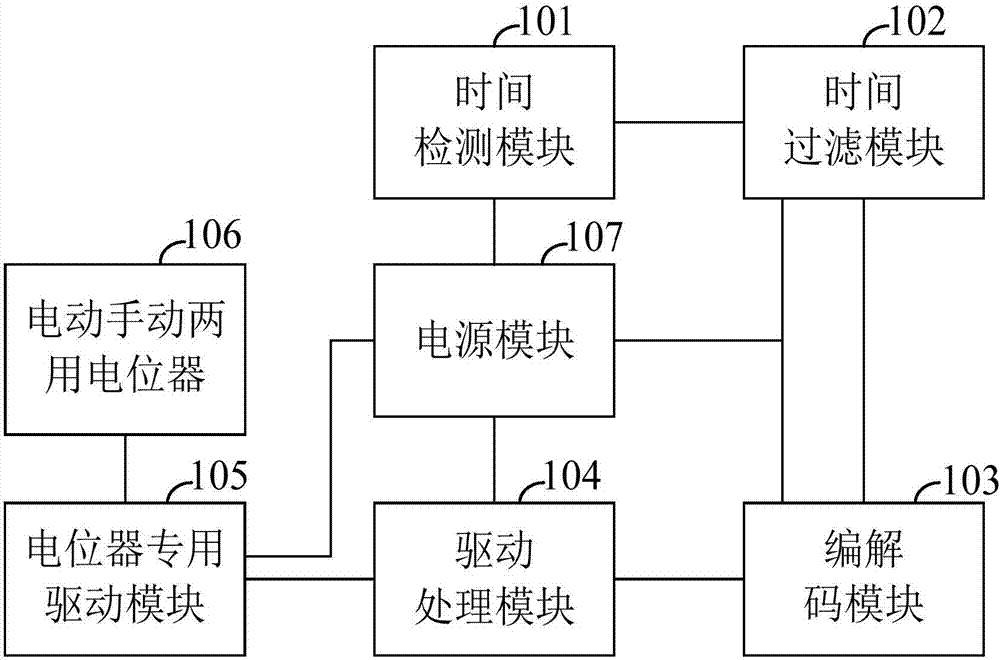

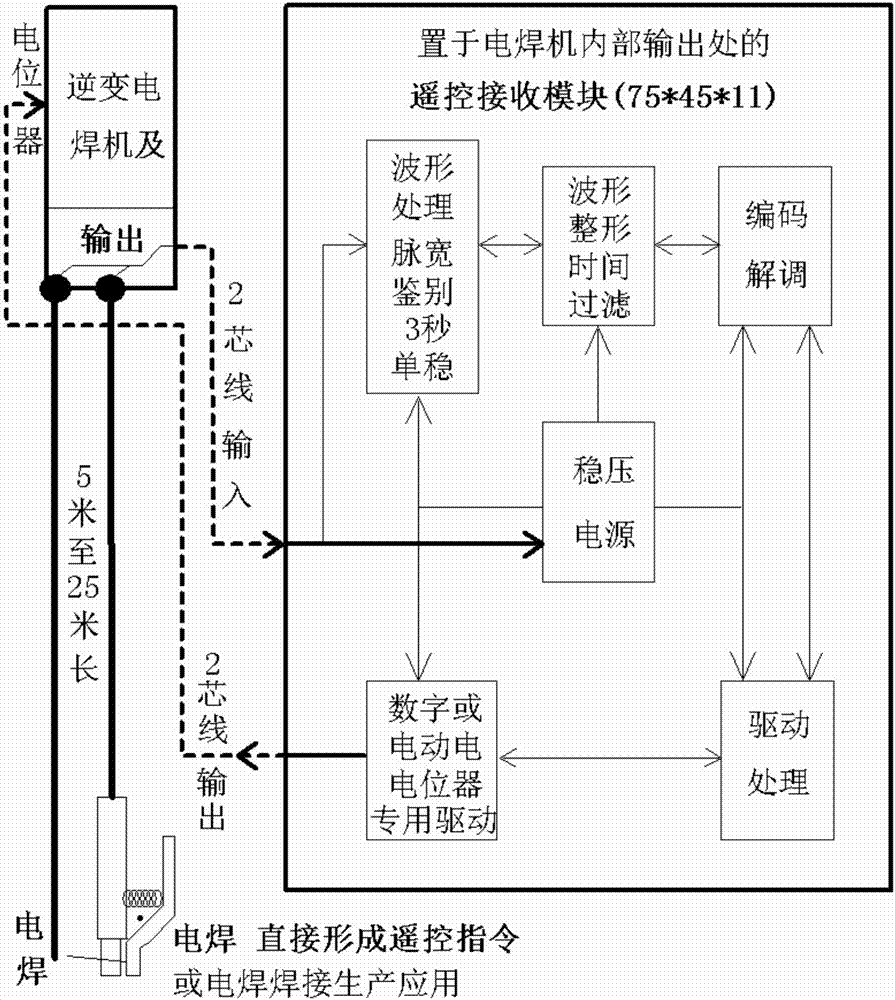

Method and device for realizing remote adjustment of inverter welding machine current based on welding time

ActiveCN106984886BImprove the speed of remote control operationBring convenienceArc welding apparatusControl engineeringDigital potentiometer

The invention provides a method and a device for realizing remote regulation of currents of an inverter welding machine based on welding time. For the particularity of manual electric arc welding occasions, regulation of the currents of the welding machine is a time-consuming, troublesome and frustrating thing for an operator. According to the method and the device for realizing the remote regulation of the currents of the inverter welding machine based on the welding time, the detected welding time is adopted as remote control commands of encoding, a remote controller is not needed any more so that the remote control and adjustment of the currents can be realized without operating any accessories, and therefore the electric welding operator can apply a remote control system simply and efficiently; receiving modules for processing the remote control commands comprise a time detecting module, a time filtering module, an encoding and decoding module and a special driver driving a digital potentiometer or an electric potentiometer to operate so as to realize stepless regulation of the currents of the welding machine; and the regulation effect of the currents can be observed by the operator and can be subjectively determined in real time. The method and the device for realizing the remote regulation of the currents of the inverter welding machine based on the welding time are suitable for the inverter welding machine for overlapping the form of wireless remote control and regulation of the currents under the condition of reserving the function of manually regulating the currents and meanwhile are suitable for the newly-designed welding machine to be integrated on a PCB.

Owner:王修华

Method and device for realizing remote regulation of currents of inverter welding machine based on welding time

ActiveCN106984886AImprove the speed of remote control operationBring convenienceArc welding apparatusShielded metal arc weldingDigital potentiometer

The invention provides a method and a device for realizing remote regulation of currents of an inverter welding machine based on welding time. For the particularity of manual electric arc welding occasions, regulation of the currents of the welding machine is a time-consuming, troublesome and frustrating thing for an operator. According to the method and the device for realizing the remote regulation of the currents of the inverter welding machine based on the welding time, the detected welding time is adopted as remote control commands of encoding, a remote controller is not needed any more so that the remote control and adjustment of the currents can be realized without operating any accessories, and therefore the electric welding operator can apply a remote control system simply and efficiently; receiving modules for processing the remote control commands comprise a time detecting module, a time filtering module, an encoding and decoding module and a special driver driving a digital potentiometer or an electric potentiometer to operate so as to realize stepless regulation of the currents of the welding machine; and the regulation effect of the currents can be observed by the operator and can be subjectively determined in real time. The method and the device for realizing the remote regulation of the currents of the inverter welding machine based on the welding time are suitable for the inverter welding machine for overlapping the form of wireless remote control and regulation of the currents under the condition of reserving the function of manually regulating the currents and meanwhile are suitable for the newly-designed welding machine to be integrated on a PCB.

Owner:王修华

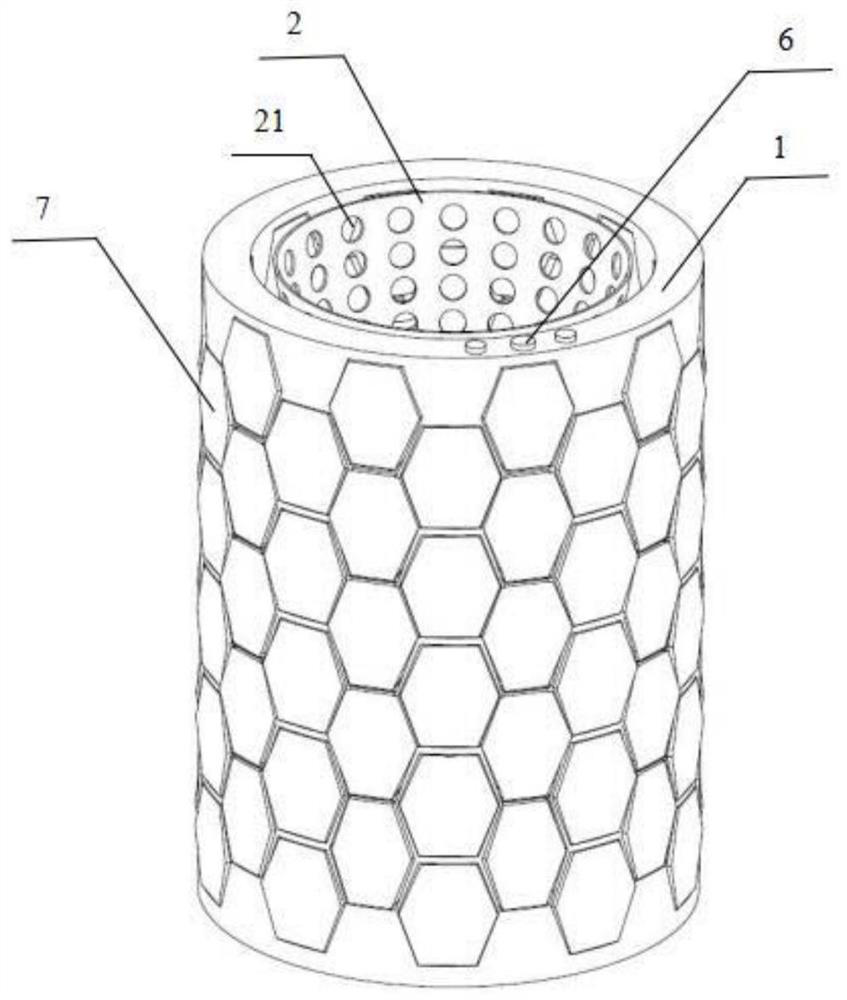

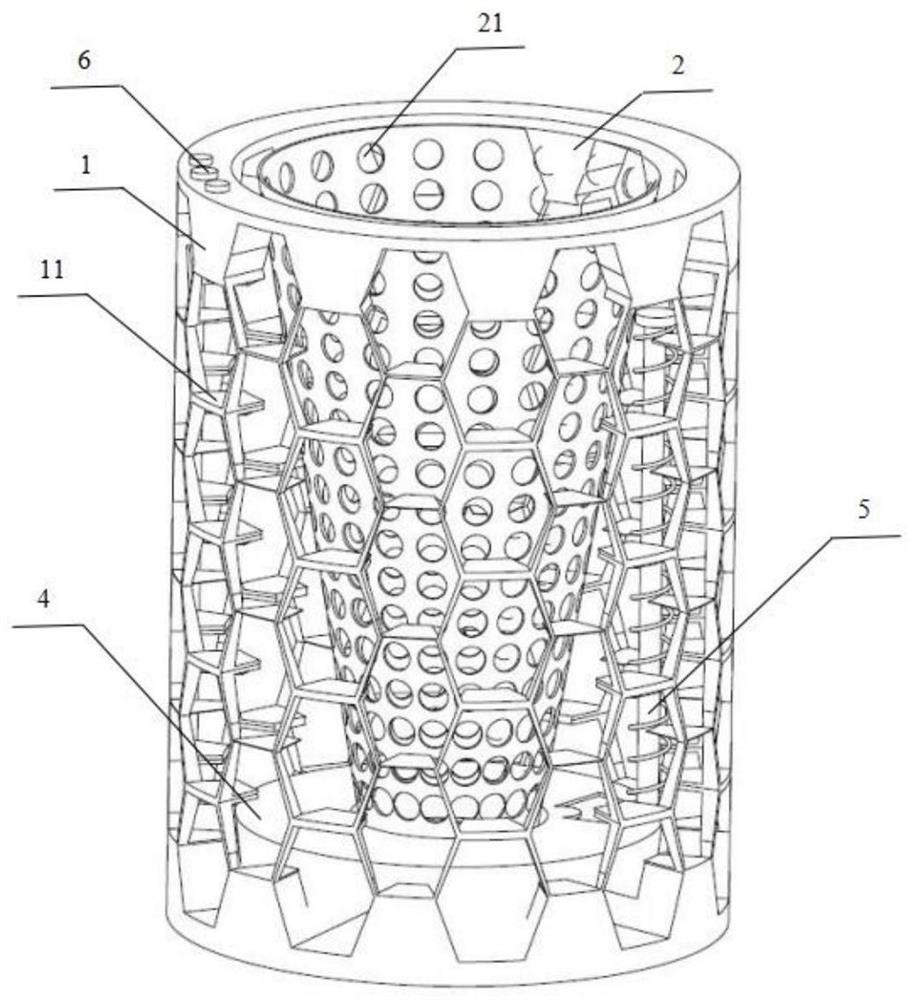

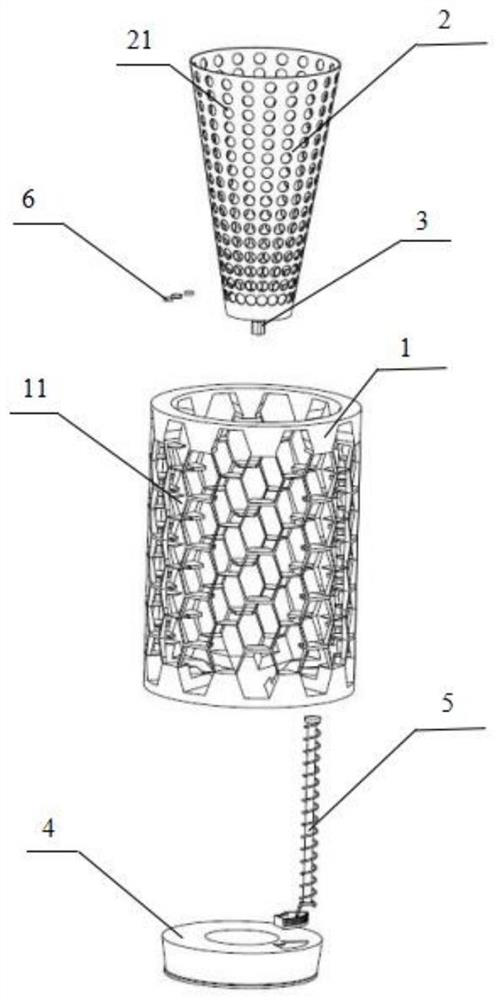

A rainwater collection pouring device and its operating method

ActiveCN109673490BSolve the problem of drying umbrellas quicklySimple structureSewerage structuresGeneral water supply conservationElectric machineAgricultural engineering

The invention discloses a rainwater collecting pouring device and an operation method thereof, comprising a plant holding device, a rotary pouring device, a storage tank, a lifting pouring device and a controller. There are several container holding grooves and at least two control buttons on the upper surface; the rotary pouring device is a hollow cone with an open upper end, which is set in the plant holding device and has several spraying holes on the surface, and a bottom. There are motors and leaking holes arranged in a circle; the storage tank is set under the plant holding device and the interior is hollow, the middle part is provided with a groove corresponding to the leaking hole of the rotary pouring device, and the upper surface is circumferentially provided with lifting pouring. The fan-shaped hole is matched and connected with the device; the lower surface of the lifting pouring device is provided with an electromagnet, and the bottom surface of the inner wall of the storage tank is provided with an energized magnetic device that matches the electromagnet. The controller is electrically connected to the control button, motor and energized magnetic device. sexual connection.

Owner:SHANGHAI INST OF TECH

Apparatus and method for facilitating return of mobile device

ActiveCN109644319AEasy to returnPrecise positioningMessaging/mailboxes/announcementsLocation information based serviceGraphicsGraphical user interface

An apparatus and method are provided to facilitate a return of a mobile device to an owner. A graphical user interface element is displayed, utilizing a display of a mobile device. A user input is detected in connection with the graphical user interface element, utilizing an input device of the mobile device. An interface is displayed including at least one return option for returning the mobile device to an owner of the mobile device, utilizing the display of the mobile device. Such interface is displayed in response to the detection of the user input in connection with the graphical user interface element utilizing the input device of the mobile device.

Owner:HUAWEI TECH CO LTD

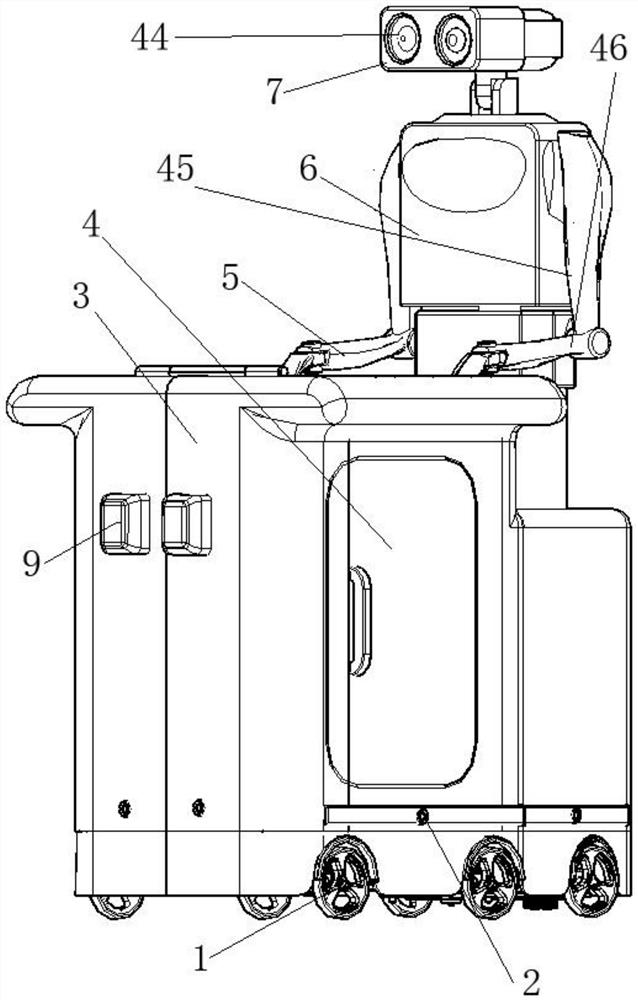

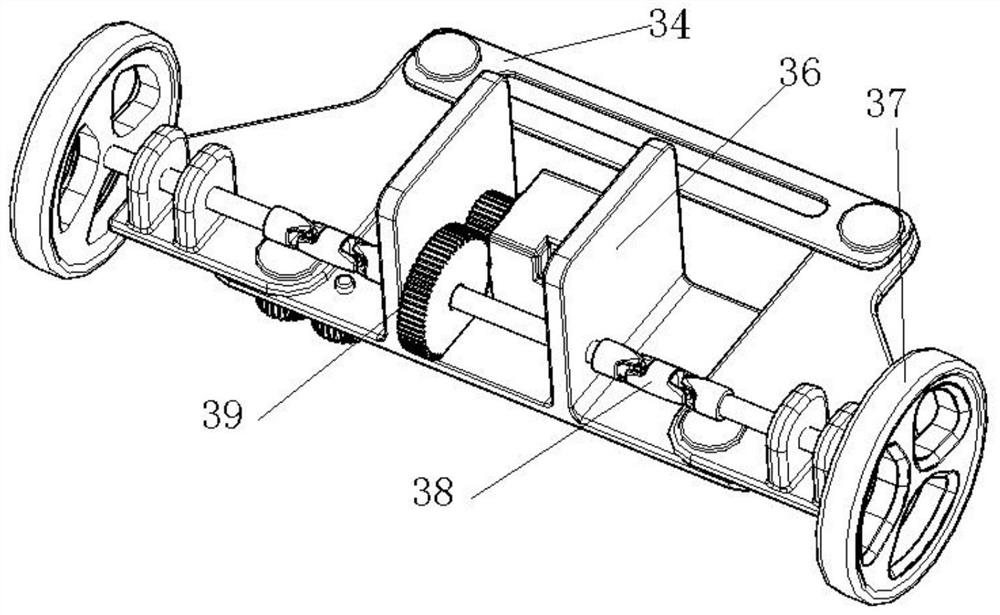

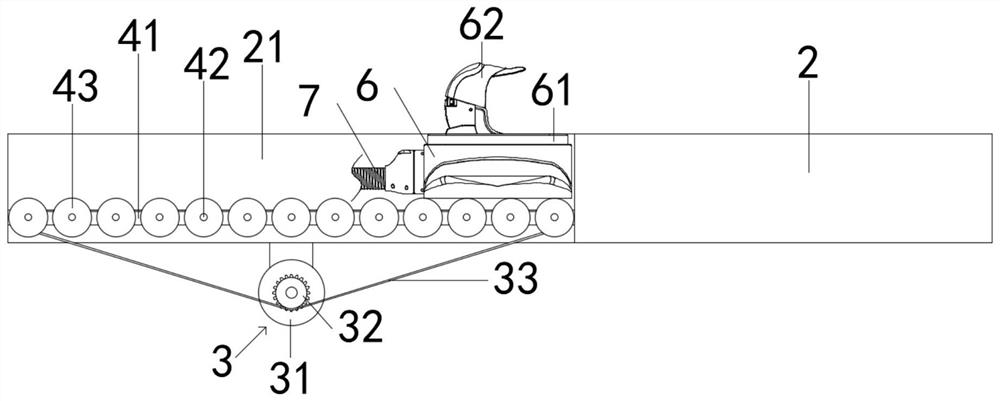

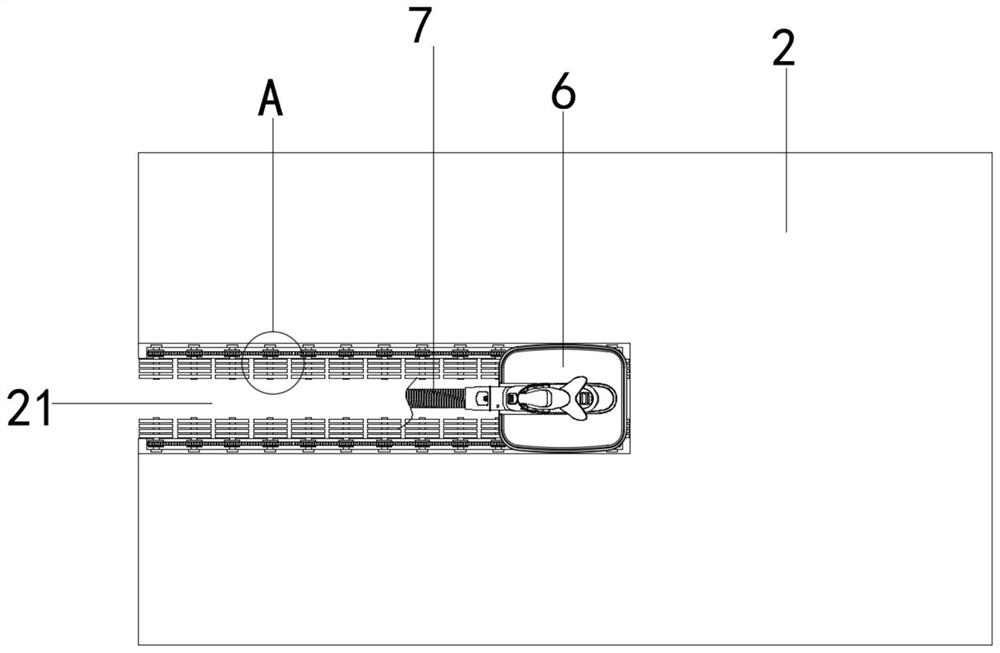

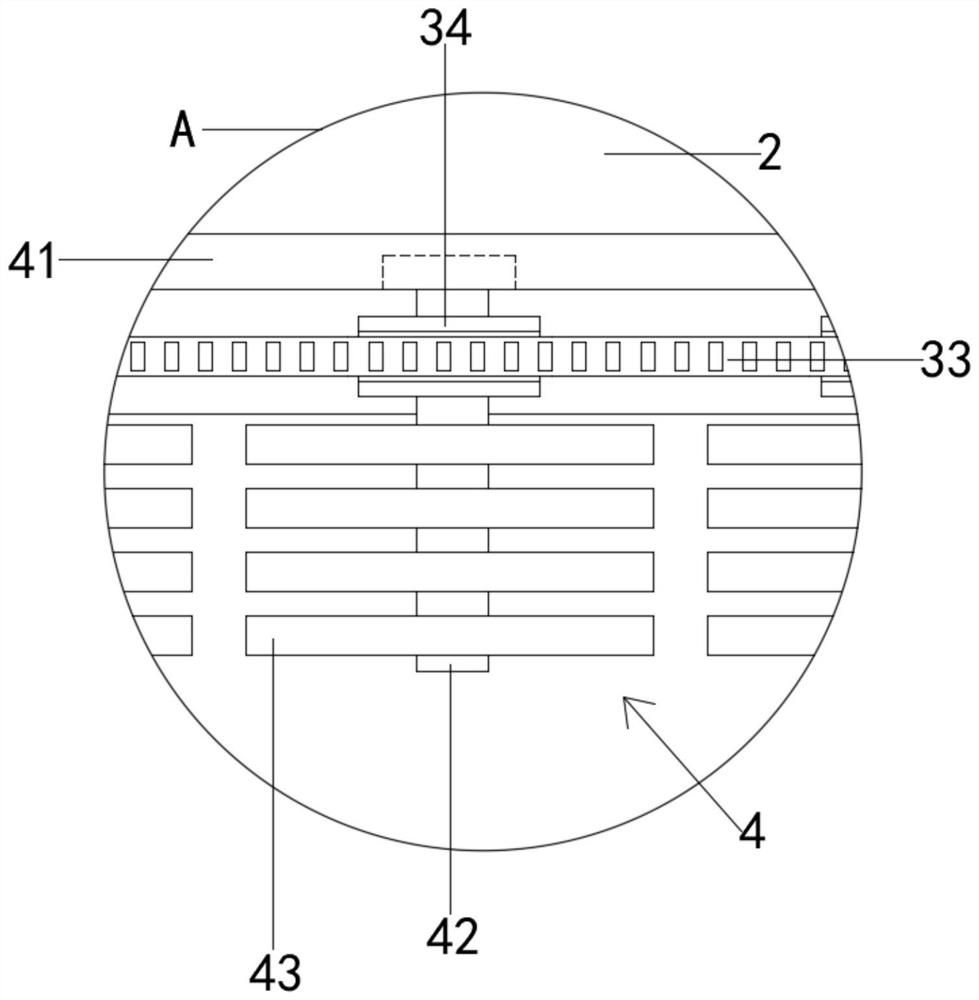

A restaurant truck

ActiveCN107186727BRealize intelligent controlReduce labor costsTable equipmentsManipulatorFood deliveryVehicle frame

The present invention discloses a dining car for restaurants, which comprises a walking frame and a plate lifting assembly arranged on the frame. The walking frame includes a car body shell with a hollow structure inside. The plate lifting assembly includes The synchronous belt transmission structure on the left and right sides of the hollow structure of the car body shell is connected by the synchronous belt power system fixed at the bottom of the frame, and the synchronous protrusions are arranged on the outer side of the synchronous belt of the two synchronous belt transmission structures; Place the dinner plate on the timing belt protrusion. The restaurant truck of the present invention has a modular design based on the shape of the existing dining truck, including a robot module, a plate lifting module, and a wheel balancing module, so as to improve the efficiency of food delivery, save manpower, and serve customers Provide more humanized, intelligent, and convenient services, and the size and appearance of the dining car are appropriate, suitable for the existing restaurant environment, and will not cause adverse effects on restaurants and customers.

Owner:NORTHEASTERN UNIV LIAONING

Call method of terminal and terminal using call method

ActiveUS9295102B2Bring convenienceImprove call qualitySpeech analysisSubstation equipmentFrequency spectrumTelecommunications

Owner:HUAWEI DEVICE CO LTD

Electronic lock cylinder device

ActiveCN106121379BImprove securityCompact cylinder structureNon-mechanical controlsHandle fastenersControl circuitMechanical engineering

The invention discloses an electronic lock cylinder device. The electronic lock cylinder device comprises a front handle, a lock container, a main shaft, a second connector, a second coupler and a hand wheel which are assembled together in the axial direction, wherein the front handle is fixedly connected with the lock container; the second coupler is fixedly connected with the hand wheel; the main shaft penetrates through a central hole of the hand wheel; when a lock is locked, the second connector freely rotates relative to at least one of the second coupler and the main shaft; when the electronic lock is unlocked, the second connector, the second coupler and the main shaft rotate together; and when the front handle is rotated, the lock container, the main shaft, the second connector and the second coupler sequentially rotate, the hand wheel is rotated, and the lock is unlocked. According to the electronic lock cylinder device, the front handle and a control circuit are respectively arranged at the two ends of the main shaft, so that the utilization convenience, reliability and safety of the electronic lock cylinder are improved.

Owner:朱英华

Full-automatic intelligent integrated defecation nursing machine

The invention belongs to the technical field of urination and defecation nursing machines, and particularly relates to a full-automatic intelligent integrated urination and defecation nursing machine. The nursing machine comprises a bed board and a nursing machine body, and a chute is formed in the inner wall of the left side of the bed plate. The nursing machine further comprises: a driving structure connected to the bed board; and a moving structure connected to one end of the driving structure, wherein the moving structure is connected to the sliding groove. The nursing machine is in contact with the moving structure; the moving structure comprises fixing plates, the fixing plates are fixedly installed on the inner walls of the two ends of the bottom of the sliding groove, rotating shafts are rotationally connected to the inner walls of the fixing plates through bearings, round plates are evenly and fixedly installed at one ends of the rotating shafts, the round plates make contact with the nursing machine, and the other ends of the rotating shafts are connected with a driving structure; and the driving structure comprises a servo motor, a first gear and a second gear, by preventing a patient from being lifted up, convenience is brought to nursing workers or the patient, the situation that the amount of exercise of the patient is too large can be avoided, and then the condition of the patient can be prevented from being aggravated.

Owner:戴恩医疗科技浙江股份有限公司

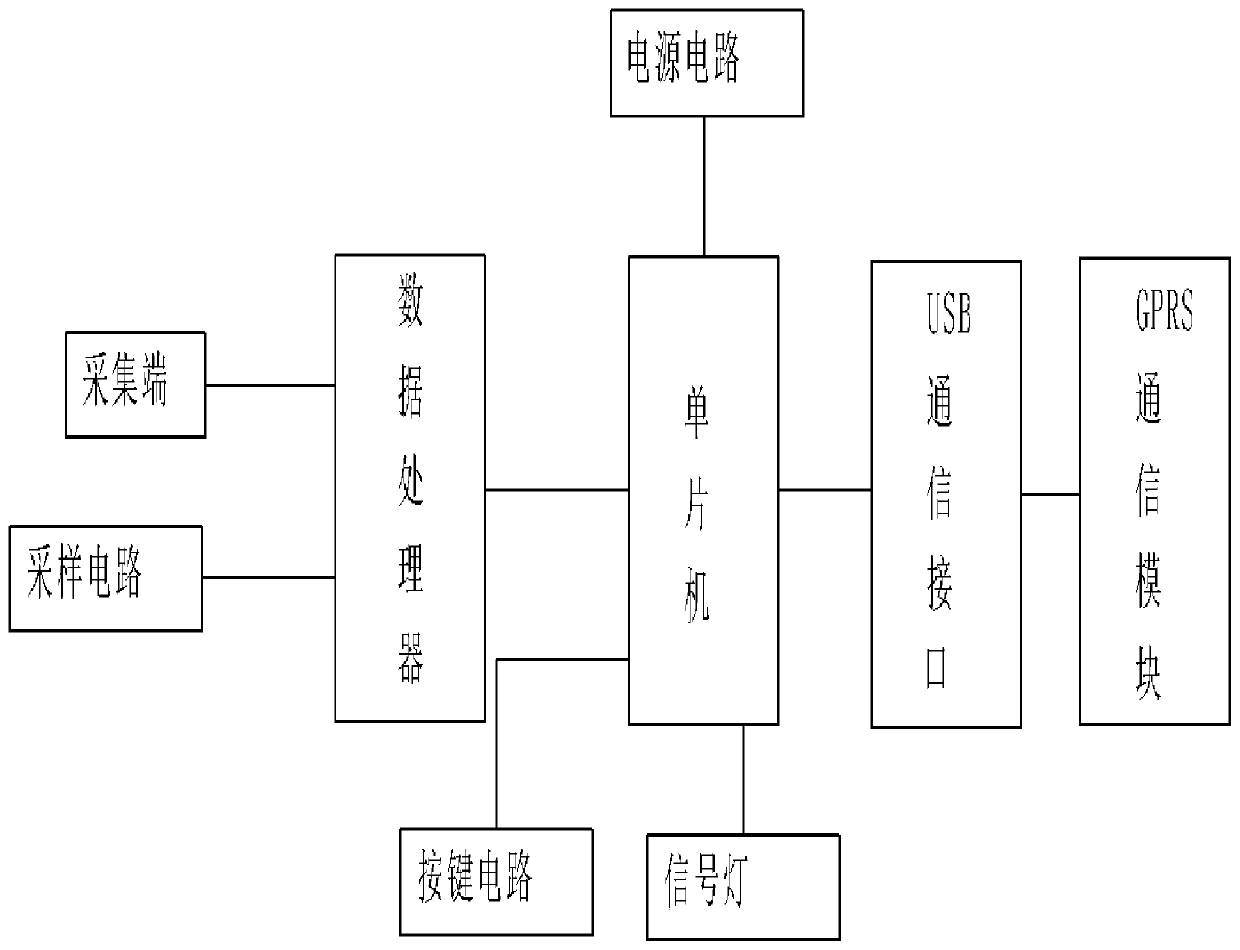

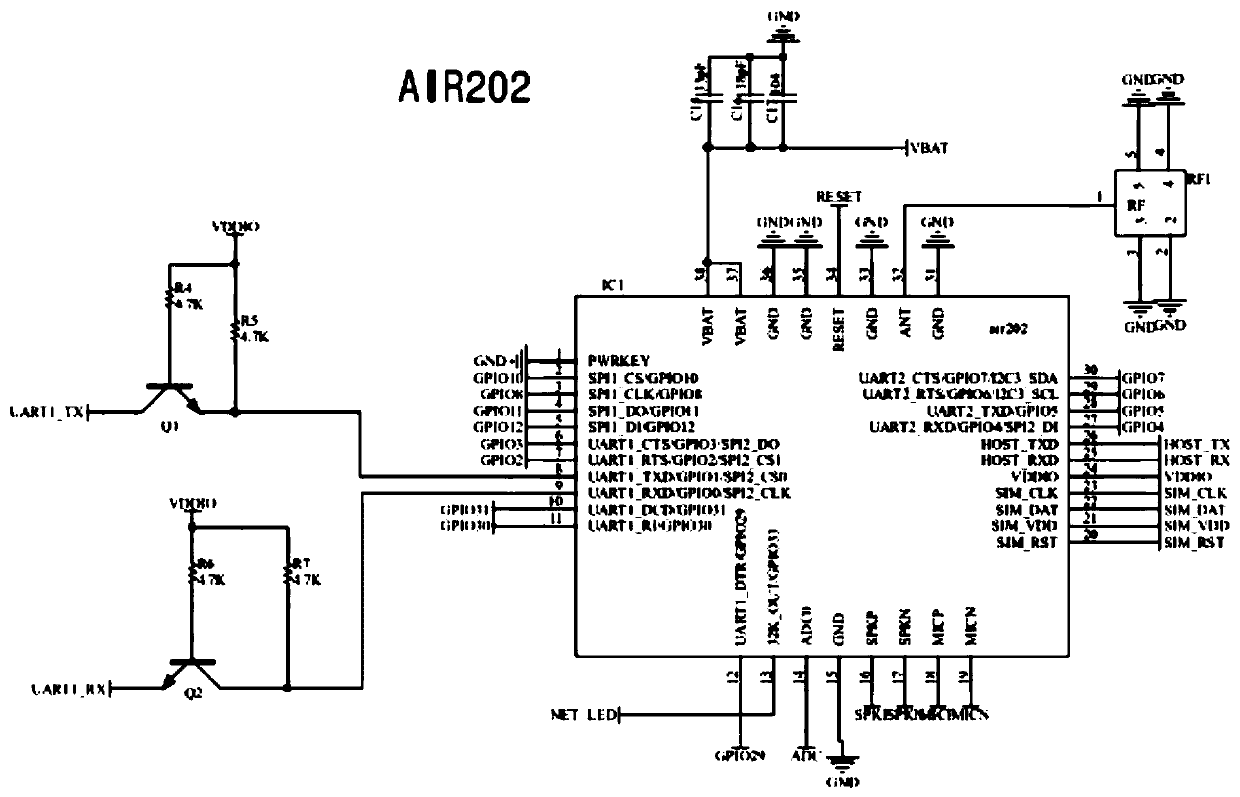

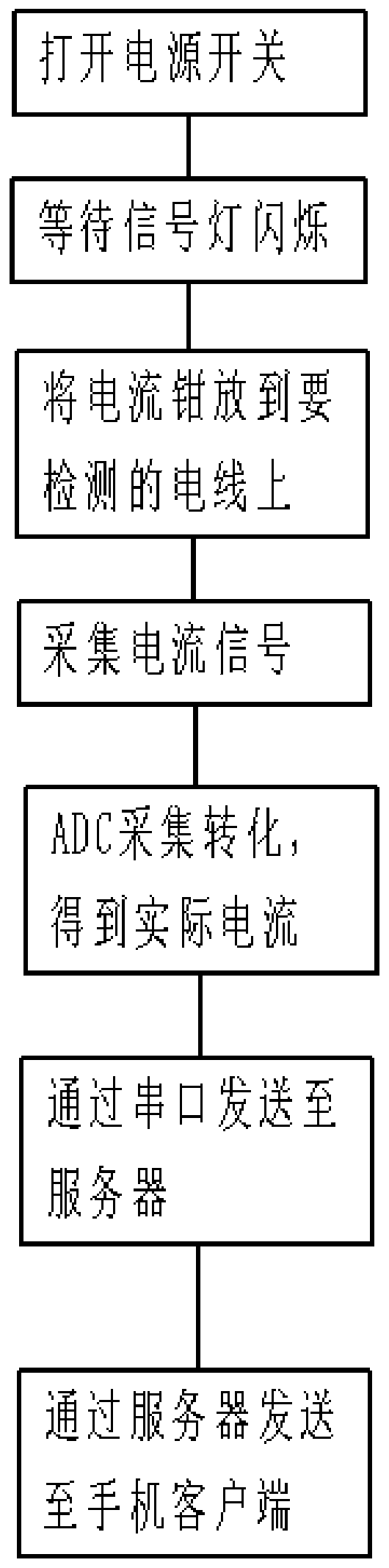

Low-voltage branch line transformer area identification instrument

PendingCN110554266AImprove work efficiencyConvenient and quick detection of currentElectrical testingMicrocomputerMicrocontroller

The invention discloses a low-voltage branch line transformer area identification instrument, which belongs to the field of power distribution detection products. The identification instrument comprises an acquisition terminal, a divider resistance sampling circuit, a data processor, a power supply circuit, a single-chip microcomputer, a signal lamp, a key circuit, a USB interface and a GPRS communication module, wherein the acquisition terminal and the divider resistance sampling circuit are respectively connected with the data processor; the data processor and the power supply circuit are respectively connected with the single-chip microcomputer; the key circuit, the signal lamp and the USB interface are connected with the single-chip microcomputer; and the GPRS communication module is connected with the USB interface. The identification instrument is reasonable in design, simple in structure, firm and stable, can detect a plurality of lines at the same time, is not affected by detection lines, and greatly improves the work efficiency of detection personnel.

Owner:STATE GRID SHANDONG ELECTRIC POWER

pcie interface, connector and terminal equipment

InactiveCN109565124BRealize transmissionBring convenienceCoupling contact membersComputer periphery connectorsComputer hardwareTerminal equipment

A PCIE interface, a connector, and a terminal device, the PCIE interface comprising: at least one pair of ports, which have a receiving function attribute and are used for receiving data; and at least one pair of ports, which have a transmitting function attribute and are used for transmitting data. Two ports of each pair of ports have opposite polarities, and each of the ports having the receiving function attribute and the transmitting function attribute has the same attribute as a port in central symmetry with the port. The interface can realize normal data transmission when inserted in both forward and reverse directions.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com