Convertible welding mold

A welding mold, front and back technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to reduce vacancy rate, improve welding efficiency and equipment utilization, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

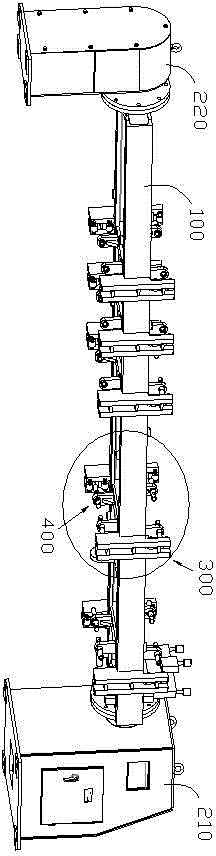

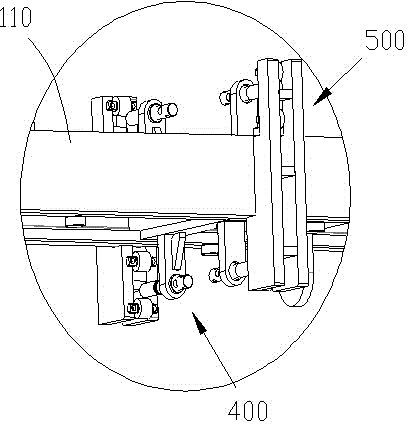

[0028] Such as figure 1 As shown, the front and back dual-purpose welding mold of the present invention includes a mold body 100 , an overturning device, an outer clamping device 300 and an inner clamping device 400 . Among them, the turning device is arranged on both sides of the mold body to provide turning power, and the inner and outer clamping devices are arranged on the front and back sides of the mold body, which can respectively position the workpiece 500 to be welded on the front and back sides of the mold body Clamping to realize continuous welding of workpieces with two different opening sizes.

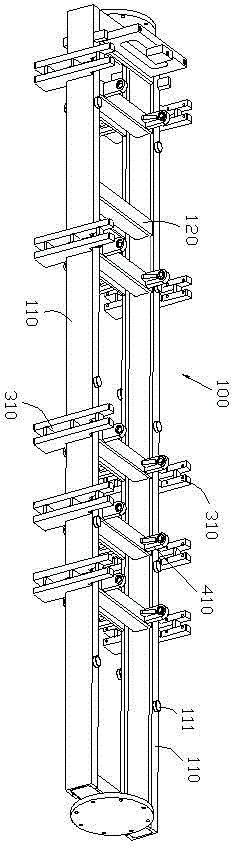

[0029] Such as figure 2 As shown, the mold body 100 is a horizontally arranged frame structure, flanges are arranged at both ends, and are fixedly connected to the turning device by bolts. The mold body 100 includes side plates 110 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com