Hybrid structure for multi-axle heavy off-road vehicle

A hybrid and off-road vehicle technology, applied in hybrid vehicles, power units, pneumatic power units, etc., can solve problems such as poor fuel economy, inability to drive the vehicle, and inability to achieve decoupling, so as to improve adaptability and improve Ability, the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

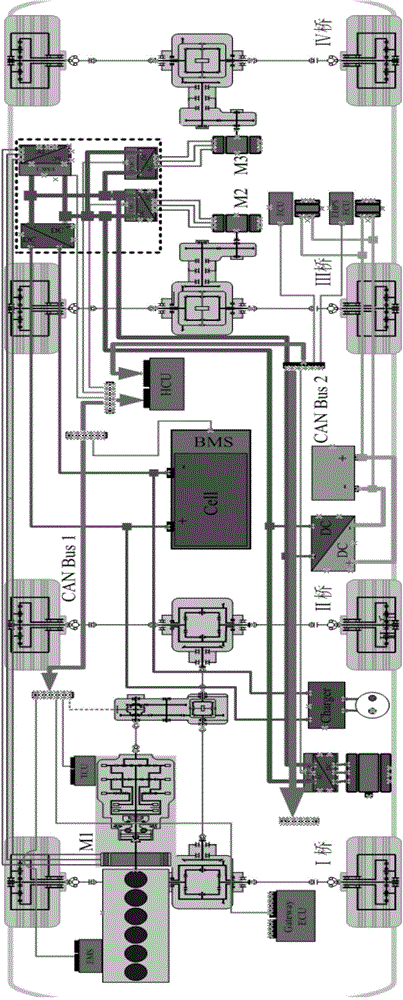

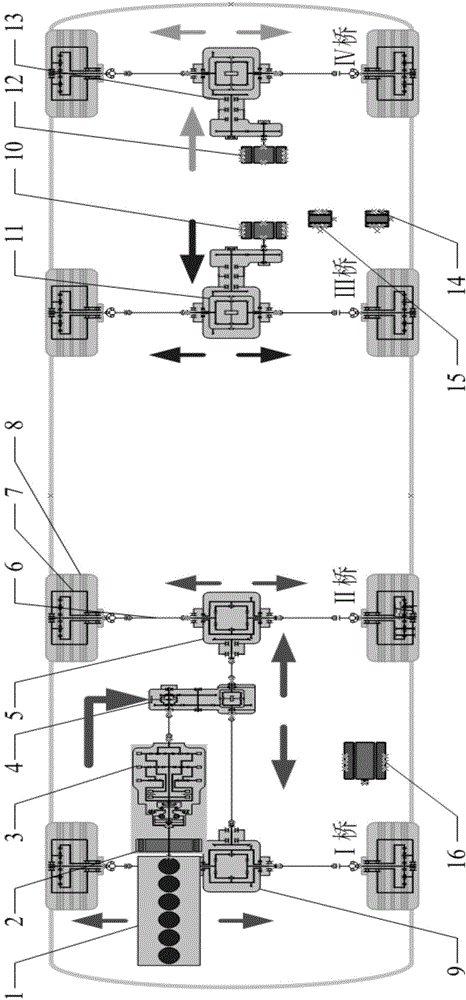

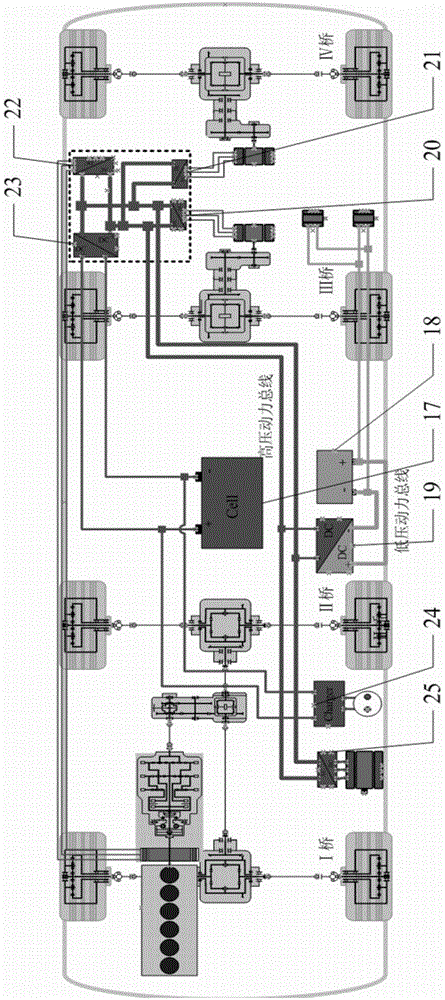

[0025] Below in conjunction with the accompanying drawings, the present invention will be described in further detail by taking the four-axle off-road vehicle as an example.

[0026] see figure 1 , a hybrid configuration of a multi-axle heavy-duty off-road vehicle provided by an embodiment of the present invention is aimed at a four-axle or above heavy-duty off-road vehicle; including: a mechanical system, an electrical system, and a control system.

[0027] see figure 2 , the mechanical system includes: engine 1, ISG motor 2, hydraulic automatic transmission 3, transfer case assembly 4, the first main reducer group, transmission shaft 6, the first wheel side reducer group, traction motor group, the second The main reducer group and the second wheel side reducer group.

[0028] The driving axle of the off-road vehicle is divided into two parts, the first driving axle unit and the second driving axle unit; in the present embodiment, the first driving axle unit includes: I ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com