Inflation sealing tape for power hatch of armored vehicle

A vehicle power, air-filled sealing technology, applied in the direction of sealing devices, vehicle parts, transportation and packaging, etc., can solve problems such as unsatisfactory sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

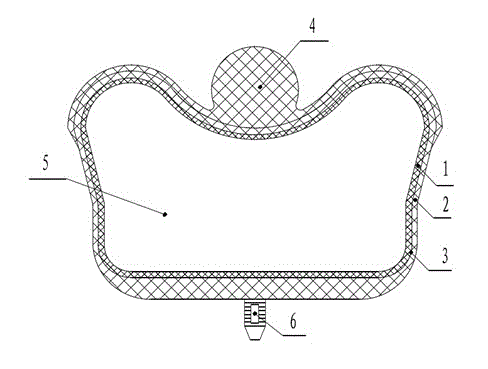

[0008] The manufacturing method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] 1. Overall vulcanization mold made by external agreement: process and manufacture the overall vulcanization mold according to the hatch cover and hatch size and sealing method.

[0010] 2. Preparation of the main rubber material: the natural rubber compound can be prepared by mixing according to the formula 5-6 of "Rubber Products Use Formula Encyclopedia".

[0011] 3. Preparation of the inner and outer rubber layer films for molding: the mixed rubber obtained in step 2 is rolled by a calender to obtain a raw film, and stored for later use.

[0012] 4. Preparation of the buffer reinforcement layer for molding (3) Coated fabric: Paste the mixed rubber obtained in step 2 on both sides of the domestic nylon knitted buffer cloth through a calender to prepare a raw rubber cloth for use.

[0013] 5. Preparation of external rubber profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com