Distributor for lifting large thin-wall safety shell and passive water tank and force transfer method thereof

A containment and passive technology, which is applied in the direction of transportation and packaging, load suspension components, etc., can solve the problems of not taking into account the large bending moment, the transition beam cannot be arranged reasonably, and the integrity of the distributor is poor, so as to reduce the shear Stress, avoiding cracking at weld joints, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, specific embodiments are described below in detail with accompanying drawings.

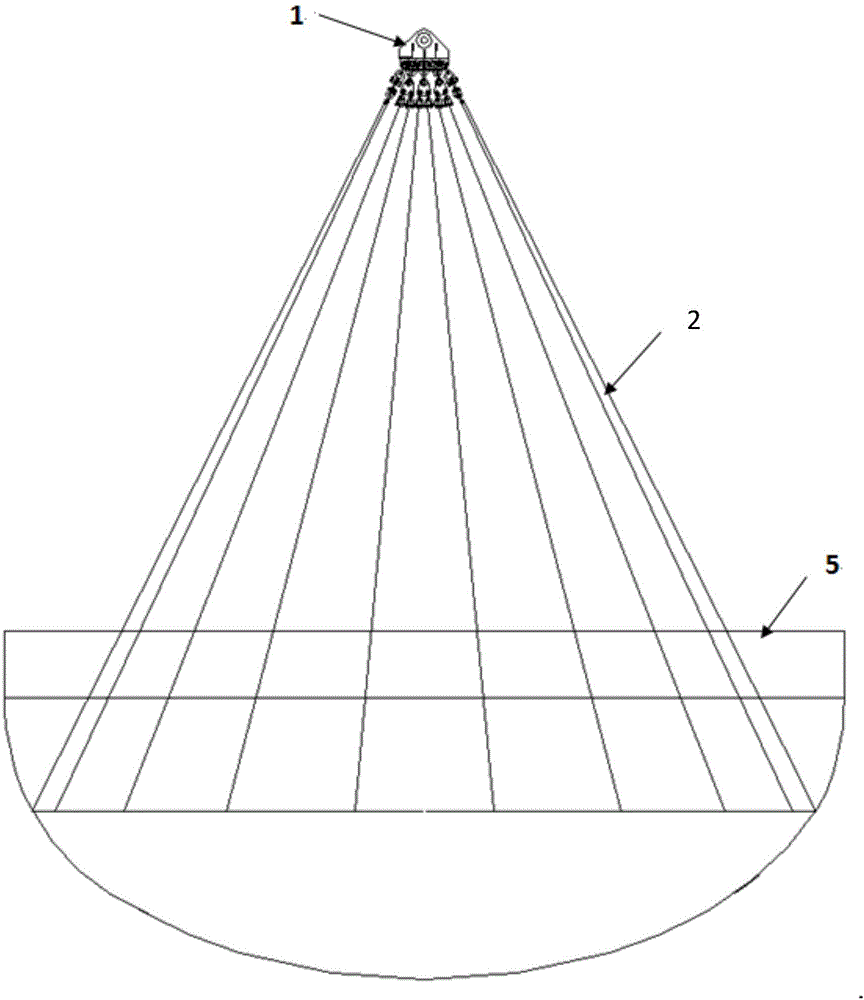

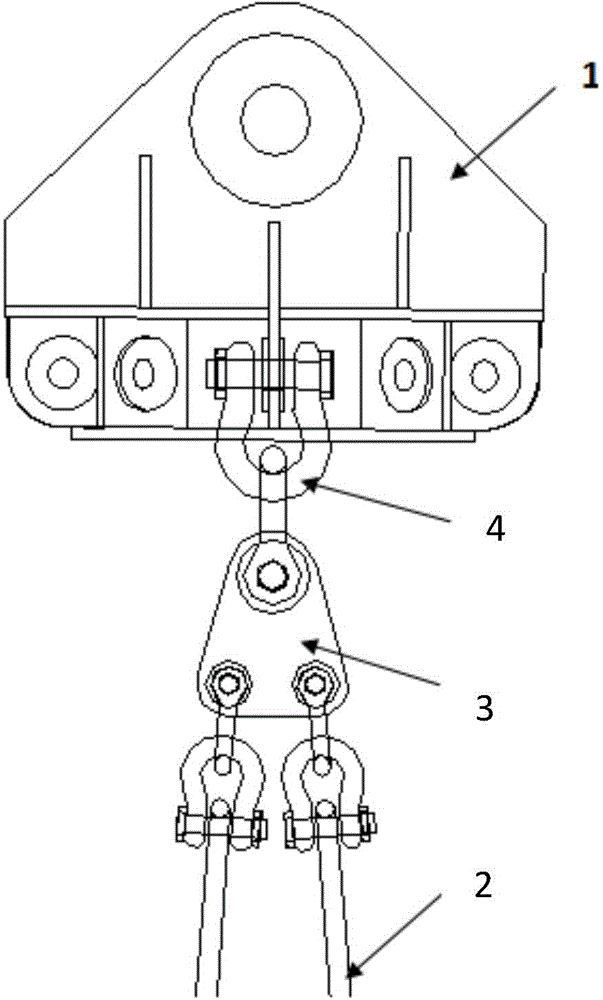

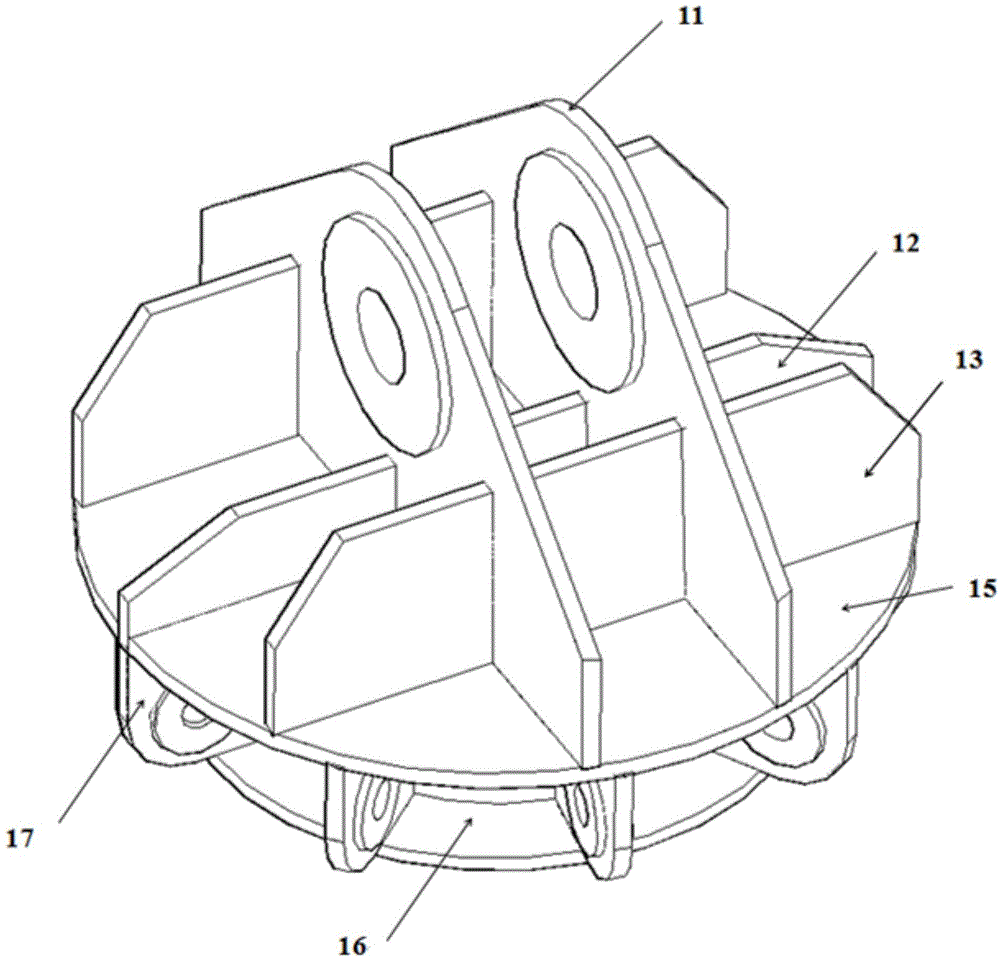

[0027] Such as image 3 As shown, the present invention provides a distributor for the hoisting of CAP1400 containment and cooling water tanks, and uses the triangular plate and the shackle connection to realize the equidistant arrangement of the slings, so that the stress on each sling is even and does not interfere with each other, ensuring safety There is no large deformation of the shell bottom head during hoisting. The present invention includes two first lifting bases 11, a second lifting base 12, two reinforcements 13, an annular support beam 14, a connecting plate 15, a bottom plate 16, and nine lug plates 17. Block triangle plate 3, shackle 4.

[0028] The two first lifting bases 11 are connected to the upper hanger through pin shafts, the second lifting base 12 is welded on the two first lifting bases 11, and two reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com