Thallium ingot ejecting system and thallium ingot ejecting methods

A technology of ejection system and titanium lump, which is applied in the field of titanium metallurgy, can solve problems such as tank wear and tank damage, and achieve the effect of avoiding excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

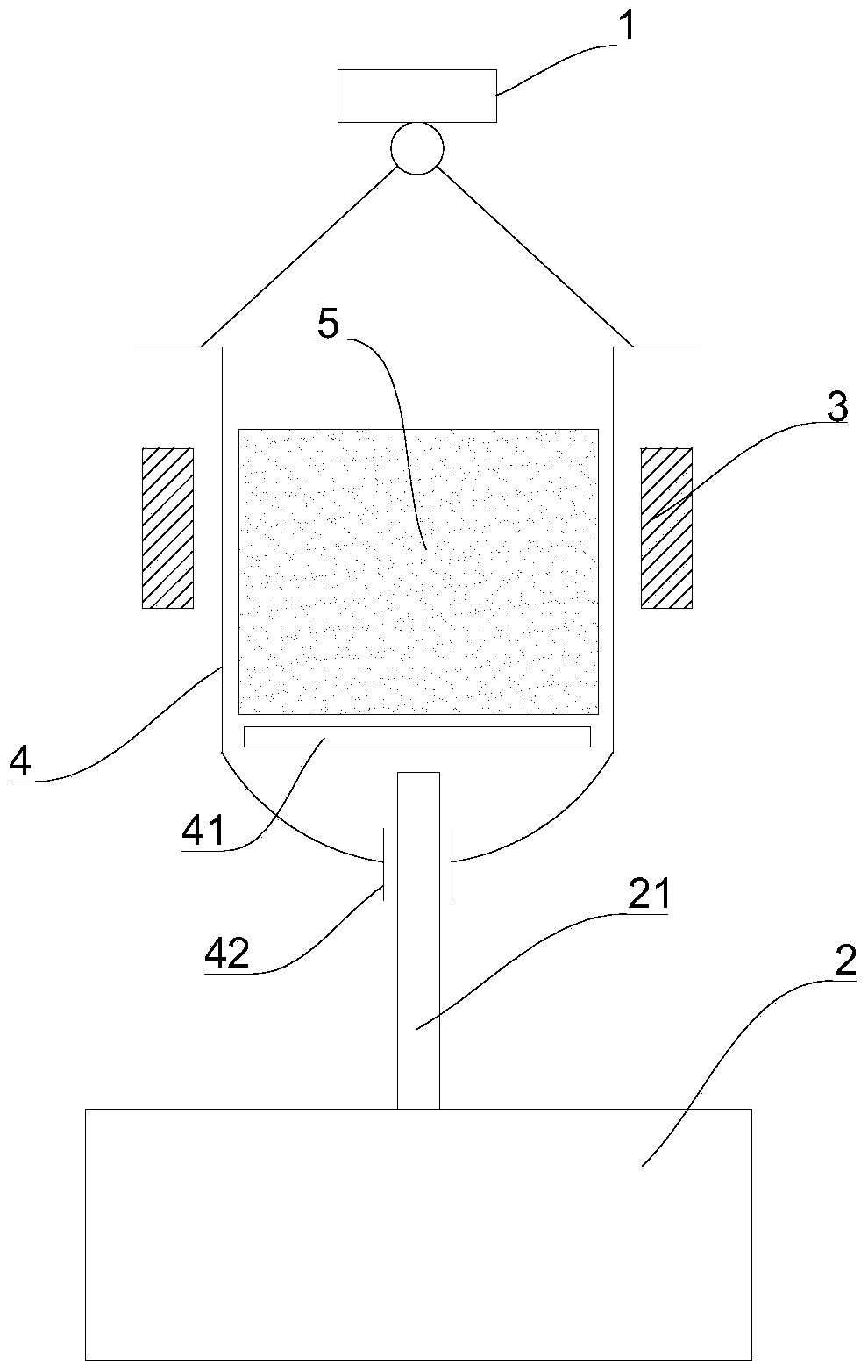

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 Shown:

[0027] The titanium lump ejection system includes a crane 1, a tank body 4 and a hydraulic mechanism 2. The crane 1 is arranged above the tank body 4 and connected to the tank body 4 through a steel cable. The hydraulic mechanism 2 is located below the tank body 4. The hydraulic mechanism 2 is provided with an upwardly protruding top column 21, and the axial direction of the top column 21 is a vertical layout. The bottom of the tank body 4 is provided with a movable bottom plate 41. The bottom hole 42 , the top column 21 is disposed in the bottom hole 42 .

[0028] In the titanium lump ejection system of the present invention, the crane 1 is used to lift the tank body 4 and transport it to the desired position, the tank body 4 is equipped with a titanium lump 5, the bottom of the tank body 4 is provided with a movable bottom plate 41, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com