Adsorption assembly for front fly hole locking device

A keyhole and component technology, which is applied to sewing machine components, textiles, papermaking, cloth pressing mechanisms, etc., can solve the problems of discontinuous distribution of pressing feet, troublesome debugging and maintenance, and inability to fix fabrics, etc., to achieve simple structure, production and maintenance. Low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

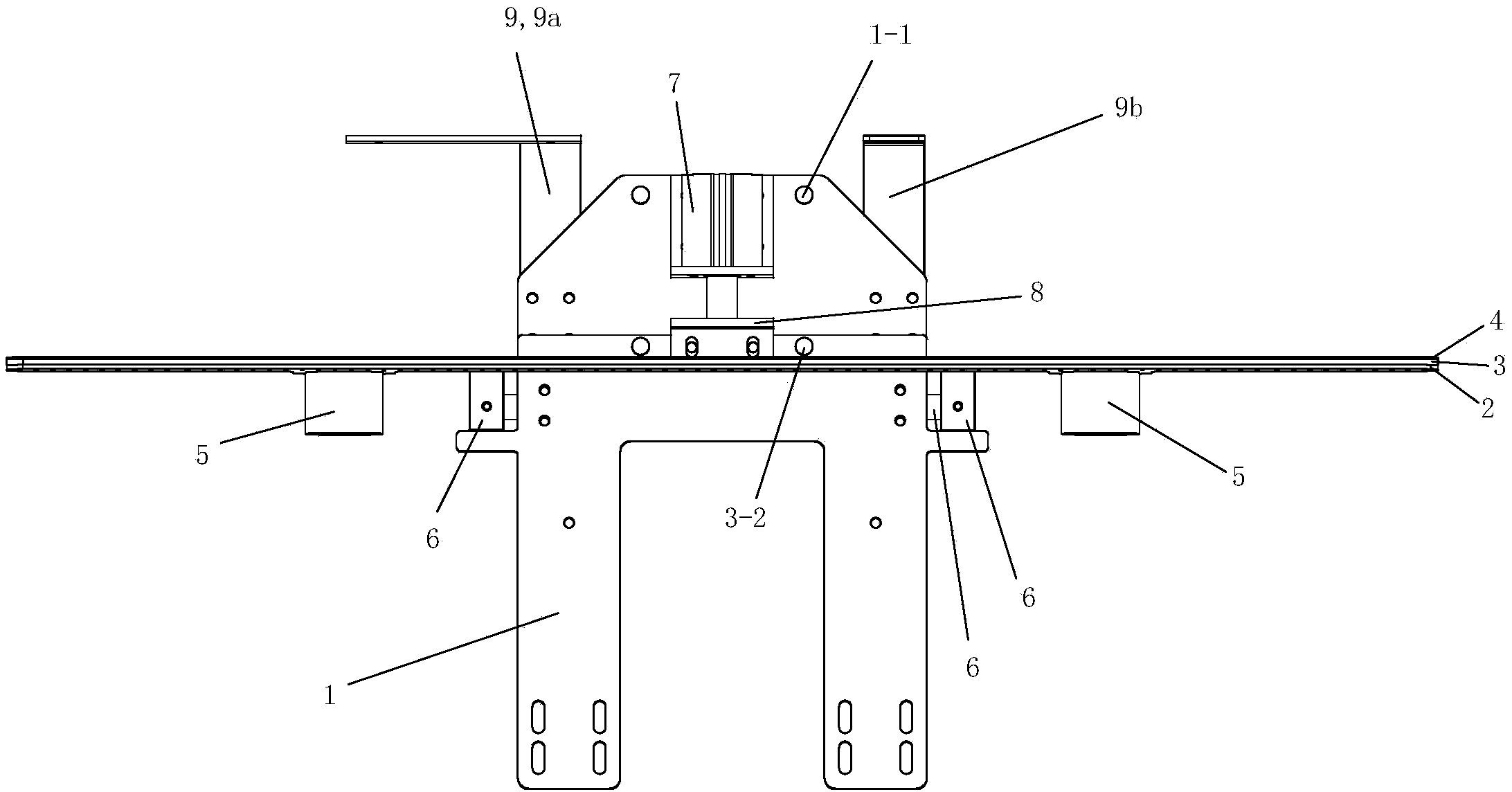

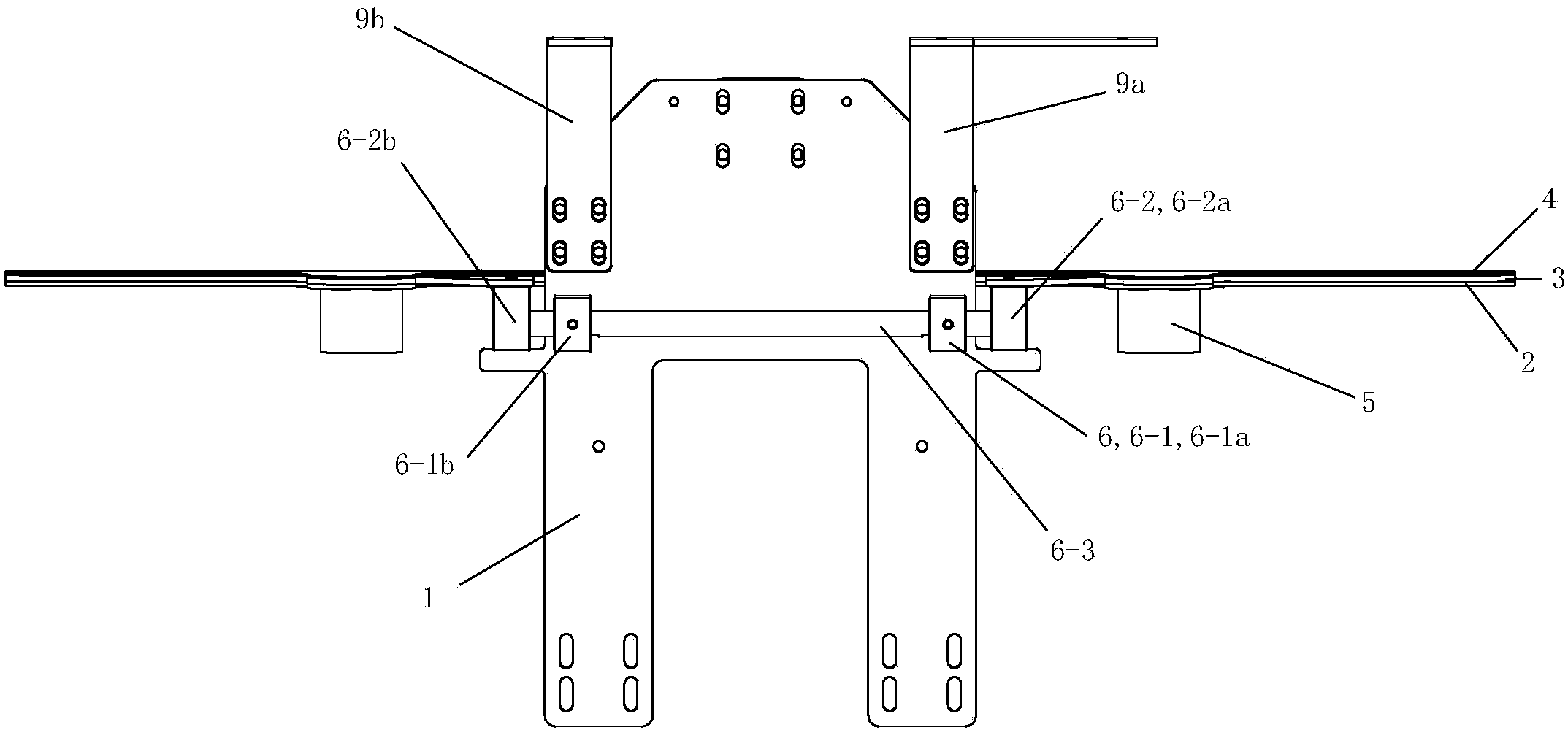

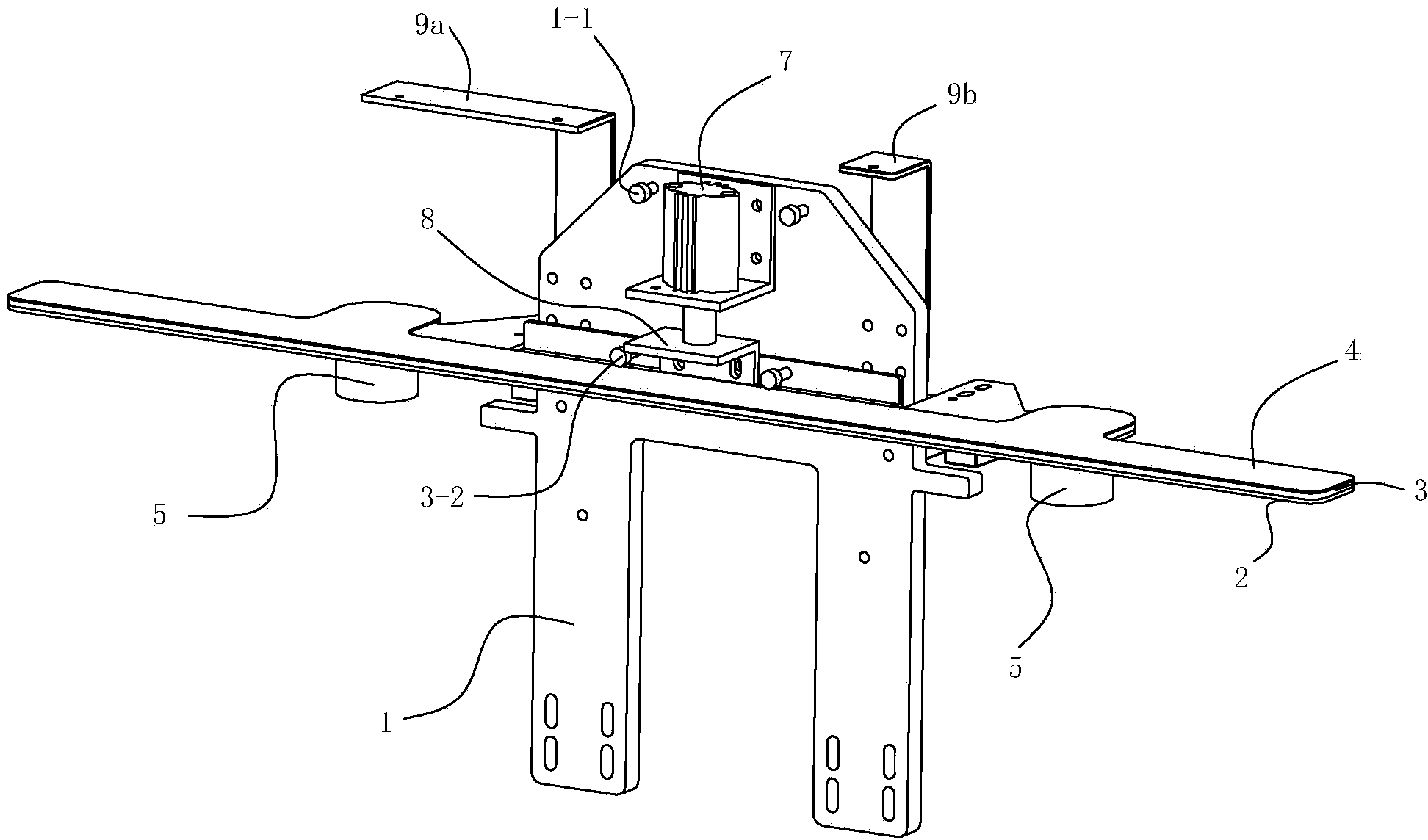

[0043] See figure 1 with figure 2, the adsorption assembly for the door lock hole device of the present invention includes a base 1, an adsorption plate 2, a frame plate 3, an upper cover plate 4, a connecting pipe 5, a connecting assembly 6, a cylinder 7, a reset assembly, a pressing plate 8, and a protective cover Fixture 9 and protective cover (not shown in the accompanying drawings of the description).

[0044] See Figure 3 to Figure 6 , The base 1 is an integral piece made of steel. The base 1 as a whole is in the form of a "U"-shaped plate with an opening downward. An upper connecting column 1-1 is respectively provided on the left and right sides of the upper front side of the base 1 .

[0045] See figure 1 , figure 2 with Figure 5 , the connecting assembly 6 includes a base connecting block 6-1, a frame plate connecting block 6-2 and a connecting shaft 6-3. There are 2 base connecting blocks 6-1, and 2 base connecting blocks 6-1 are divided into left base c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com