Special-purpose softening agent for papermaking

A technology of softener and active agent, applied in the field of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

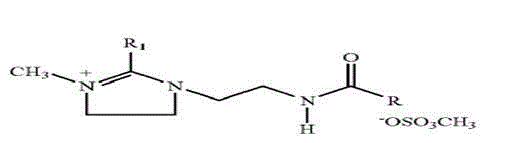

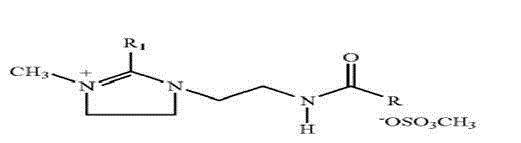

Image

Examples

Embodiment 1

[0026] Imidazoline quaternary ammonium salt 15%

[0027] Polyethylene glycol diester oleate 60%

[0028] Isotridecanyl Phosphate 10%

[0029] Polyethylene glycol PEG400 15%

[0030] Add imidazoline quaternary ammonium salt, oleic acid polyethylene glycol diester, isotridecanyl phosphate, and polyethylene glycol PEG400 into the reactor in sequence, stir at room temperature for 1.5 to 2.0 hours, and fully mix the components Get the product evenly.

Embodiment 2

[0032] Imidazoline quaternary ammonium salt 20%

[0033] Polypropylene glycol diester laurate 45%

[0034] Isotridecanyl Phosphate 15%

[0035] Glycerol 20%

[0036] Add imidazoline quaternary ammonium salt, polypropylene glycol diester laurate, isotridecanyl phosphate, and glycerol into the reactor in sequence, stir at room temperature for 1.5 to 2.0 hours, and fully mix the components to obtain the product .

Embodiment 3

[0038] Imidazoline quaternary ammonium salt 5%

[0039] Polyethylene glycol diester oleate 70%

[0040] Fatty Alcohol Ether Phosphate 5%

[0041] Polyethylene glycol PEG400 20%

[0042] Add imidazoline quaternary ammonium salt, oleic acid polyethylene glycol diester, fatty alcohol ether phosphate, and polyethylene glycol PEG400 into the reactor in sequence, stir at room temperature for 1.5 to 2.0 hours, and fully mix the components Instant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com