Pumping device for PE (polyethylene) screen pipe well completion of coal-bed gas horizontal well and pumping method

A technology of screen tube completion and pumping device, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of blocked flow channel, a large amount of pulverized coal, falling, etc., and achieve the effect of avoiding jamming accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

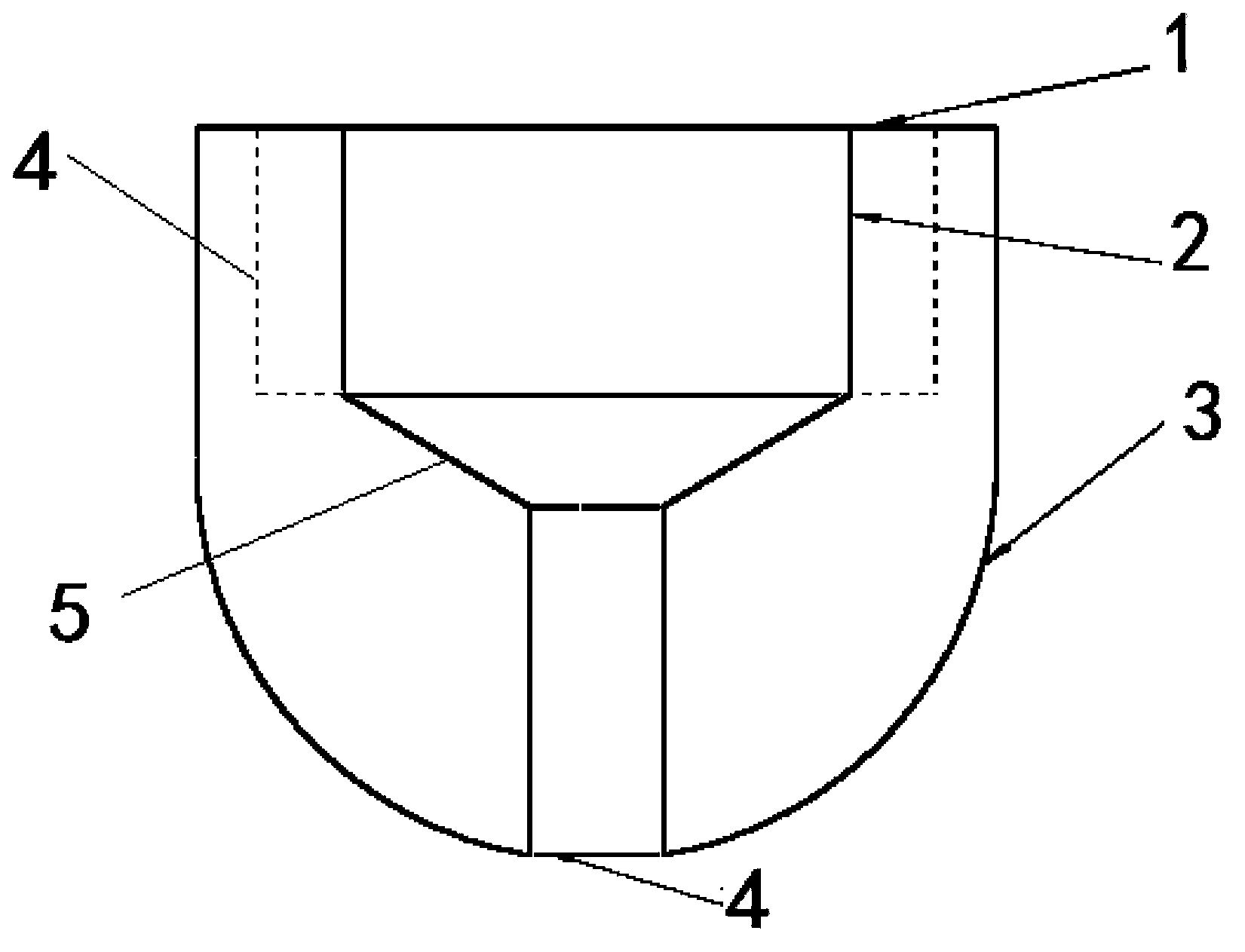

[0028] Embodiment 1: as figure 1 as shown,

[0029] A pumping device for PE screen pipe completion of coalbed methane horizontal well; the upper end of the main body is a pressure bearing surface 1, the middle part of the pressure bearing surface 1 has a guide hole 2, and a threaded connection part 4 is provided in the guide hole 2; the lower end of the main body is The hemispherical guide head 3; the discharge hole 4 is connected to the guide hole 2, the other end of the discharge hole 4 is the middle part of the hemispherical guide head 3, and the connecting part between the discharge hole 4 and the guide hole 2 is an inclined plane 5.

[0030] After the coal seam collapses in the layer where the pumping device is located, the liquid (gas) flow can flow through the guide hole 2 from the upper guide mechanism and enter the discharge hole 4, and then flow out from the discharge hole 4.

[0031] According to the conditions of the drilling tools at the well site, the drilling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com