Ultrahigh-pressure release valve

A technology of ultra-high pressure and pressure relief valves, applied in the field of pressure relief valves, can solve problems such as unreasonable sealing structure, leakage of pressure medium, fragile return spring, etc., and achieve the effects of reasonable structure improvement, increased service life and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

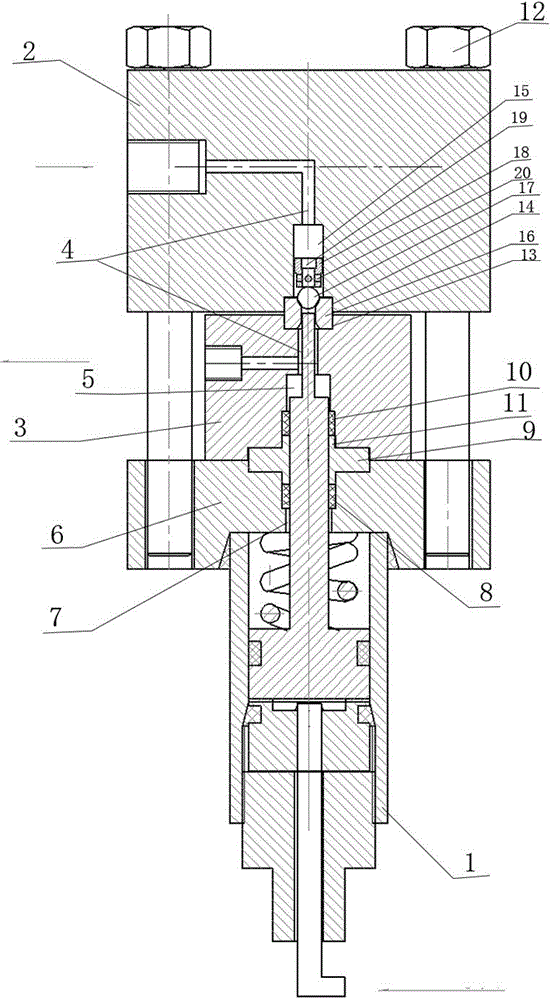

[0010] The ultra-high pressure relief valve includes an ultra-high pressure check valve and a hydraulic cylinder 1 for driving the opening and closing of the ultra-high pressure check valve; the ultra-high pressure check valve includes an upper valve block 2 and a lower valve block 3, the upper valve block and the There are valve holes 4 communicating with each other on the lower valve block respectively. The valve holes on the lower valve block 3 are folded holes formed by a vertical section and a horizontal section. The control hole 5 is a control hole 5 that is connected with each other and the axis coincides. The control hole 5 is a stepped hole composed of at least three stages with smaller diameters from bottom to top; the piston rod extension end of the cylinder barrel of the hydraulic cylinder is fixed with a flange. The cover plate 6 and the flange cover plate 6 are provided with a piston rod through hole 7, and the piston rod through hole 7 is a stepped hole composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com