Generator rotor winding temperature online monitoring method

A technology for generator rotors and rotor windings, applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the problems of generator dust, oil, water mist, complex tests, and short response times Slow down and other problems, to achieve the effect of improving monitoring work efficiency, accurate measurement accuracy, and eliminating voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

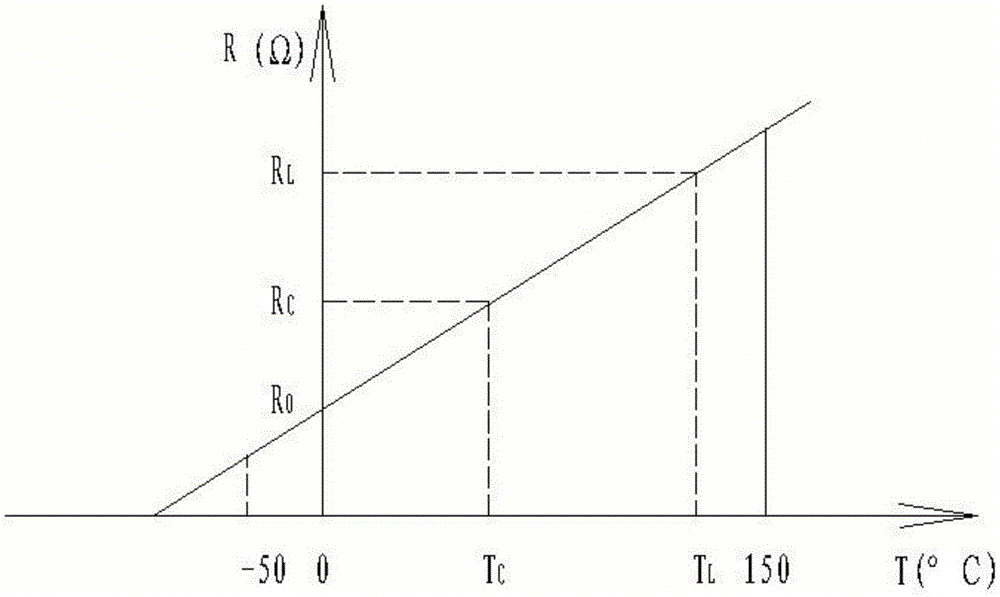

[0032] Embodiment 1, according to the generator excitation system parameter table provided by the generator manufacturer, a certain temperature T can be directly obtained C The corresponding rotor winding resistance R C , and then according to the definition of the resistance-temperature coefficient α of the rotor winding copper bar material, the formula T can be obtained L =(R L -R C ) / (α×R 0 )+T C , so as to calculate the real-time temperature T of the rotor winding 2 L . Among them, α is a constant 0.00393, R 0 is the temperature T provided by the manufacturer C The corresponding rotor winding resistance R C Converted to the resistance value of the rotor winding at 0°C, R 0 = R C / (1+α×T C ).

Embodiment 2

[0033] Embodiment 2, according to the definition of the resistance-temperature coefficient α of the copper bar material of the rotor winding, and the resistance-temperature curve of the copper bar material of the rotor winding ( image 3 ), you can get the formula T L =T C ×(R L -R 0 ) / (R C -R 0 ), so as to calculate the real-time temperature T of the rotor winding 2 L . Among them, R 0 is the temperature T provided by the manufacturer C The corresponding rotor winding resistance R C Converted to the resistance value of the rotor winding at 0°C, R 0 = R C / (1+α×T C ), α is a constant 0.00393. When given R C itself is T C When is the resistance value at 0°C, the real-time temperature T of the rotor winding L =(R L / R C -1) / α.

Embodiment 3

[0034] Embodiment 3, according to the resistance-temperature curve ( Figure 4 ), you can get the formula T L =(T C +235)×R L / R C -235, so as to calculate the real-time temperature T of the rotor winding 2 L .

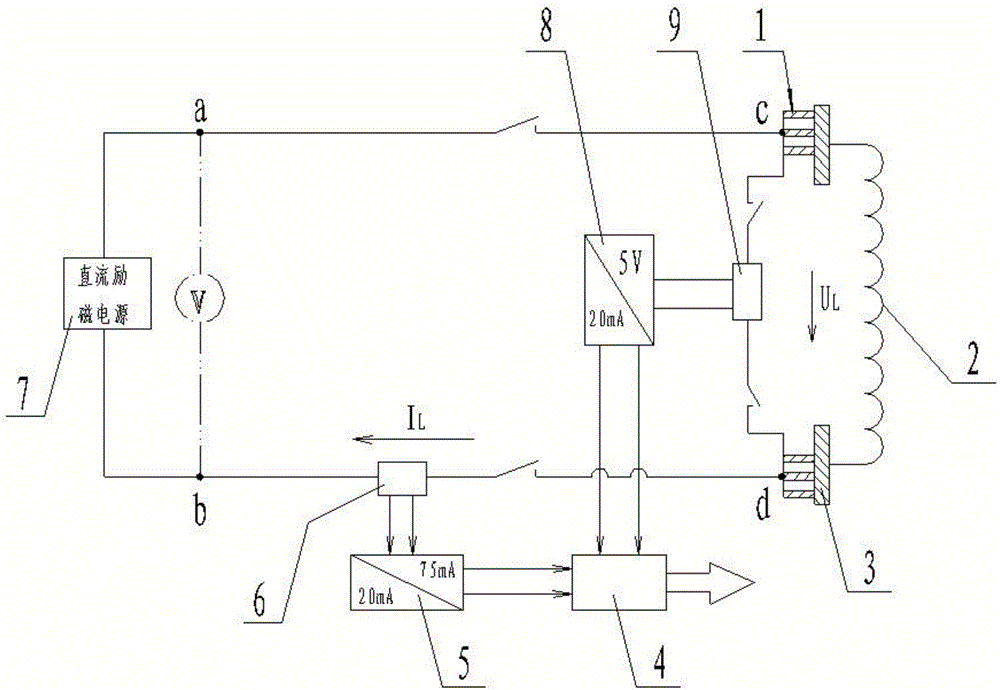

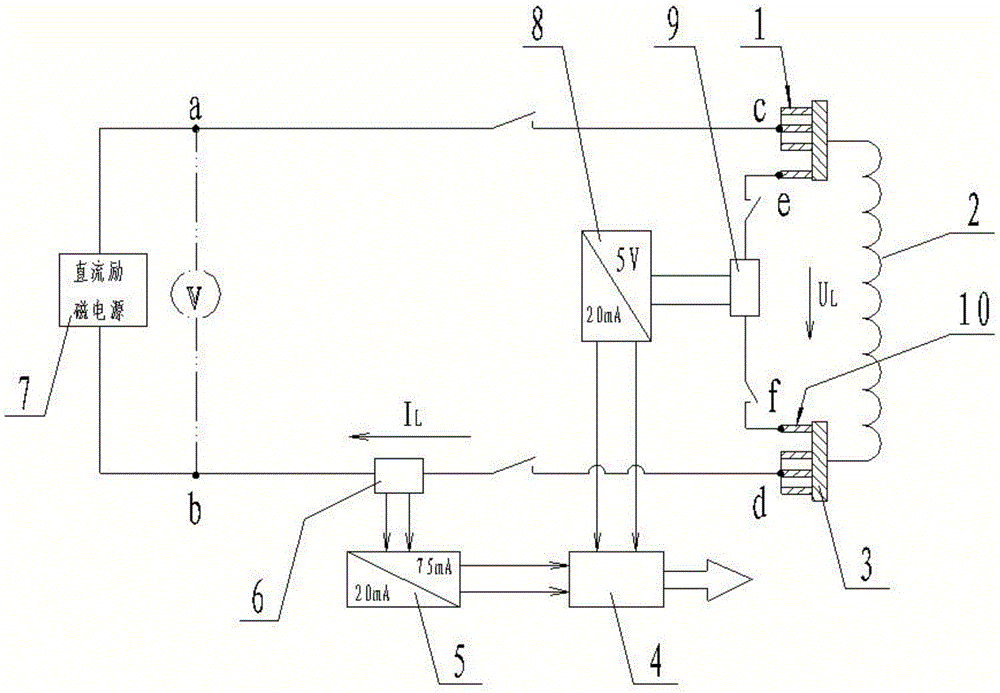

[0035] In order to further eliminate the influence of the resistance of the carbon brush group 1 and the contact resistance between the carbon brush group 1 and the slip ring 3 on the monitoring temperature, on the basis of the above-mentioned embodiments, it is also possible to use figure 2 The connection method directly collects the DC voltage U between the two slip rings L . That is: the DC excitation power supply 7 is connected to the two carbon brush groups 1 respectively fixed on the two slip rings 3 to form a circuit, and an auxiliary carbon brush 10 electrically isolated from the corresponding carbon brush group 1 is added to each of the two slip rings 3 as a voltage Monitoring point: collect the DC voltage U between the two carbon brush groups 1 in re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com