Novel mechanical force measuring machine and calibration method

A mechanical, dynamometer technology, applied in the field of measuring instruments, can solve the problems of inconvenient installation and maintenance of the power mechanism, and the easy damage of the cycloidal pinwheel reducer, so as to reduce the volume and weight, improve the accuracy and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

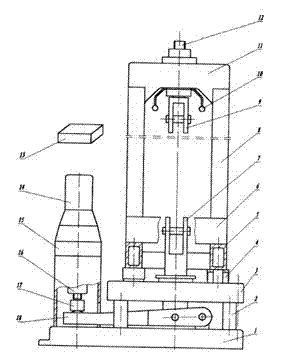

[0021] Below in conjunction with accompanying drawing, the present invention is described:

[0022] The high-precision mechanical lateral force machine is composed of a body, a frame, a load cell group 2 , a power mechanism, a pressurizing mechanism, a compression displacement doubling mechanism and an operating instrument 13 . The body is composed of a base 1 and a load-bearing platform 3, and a sensor group 2 composed of four load cells is placed between the base 1 and the load-bearing platform 3; the four-column frame 8 is on the top of the load-bearing platform 3; Between the table tops of the load-bearing platform 3, there is a compression displacement multiplication mechanism composed of four disc spring groups 4: a clamping mechanism composed of an adjusting screw 12, a handle 10 and an upper clamp 9 is installed on the beam 11 of the four-column frame. Adjust the corresponding position according to the size of the measured object. The clamping mechanism can also rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com