Method for rapidly preparing sheet by powdered phosphorite

A phosphorite and powdery technology is used in the field of rapid preparation of powdered phosphorite for observation of thin sections under a polarized light microscope. Test cycle, low cost, time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

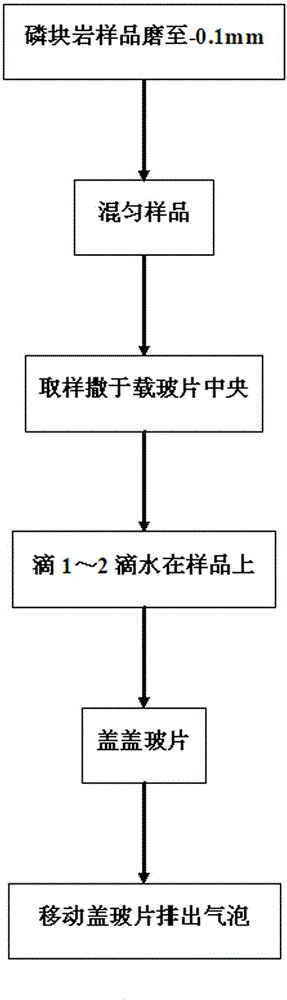

[0017] The operation steps of the sheet making method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 Shown: the process of the present invention is as follows: (1) mix evenly the powdered (general particle size below 0.1mm) phosphorite sample; (2) take a small amount of phosphorite sample with a small spoon and sprinkle it on the center of the glass slide; (3) Use a dropper to drop 1 to 2 drops of water on the place where the mineral sample is sprinkled; (4) Cover the mineral sample with a cover glass, and slide the cover glass back and forth gently with the index finger, the purpose is to make the cover glass and The air bubbles between the glass slides are discharged, and the mineral samples are evenly dispersed. If the ore sample is evenly dispersed, qualified phosphorite flakes can be obtained.

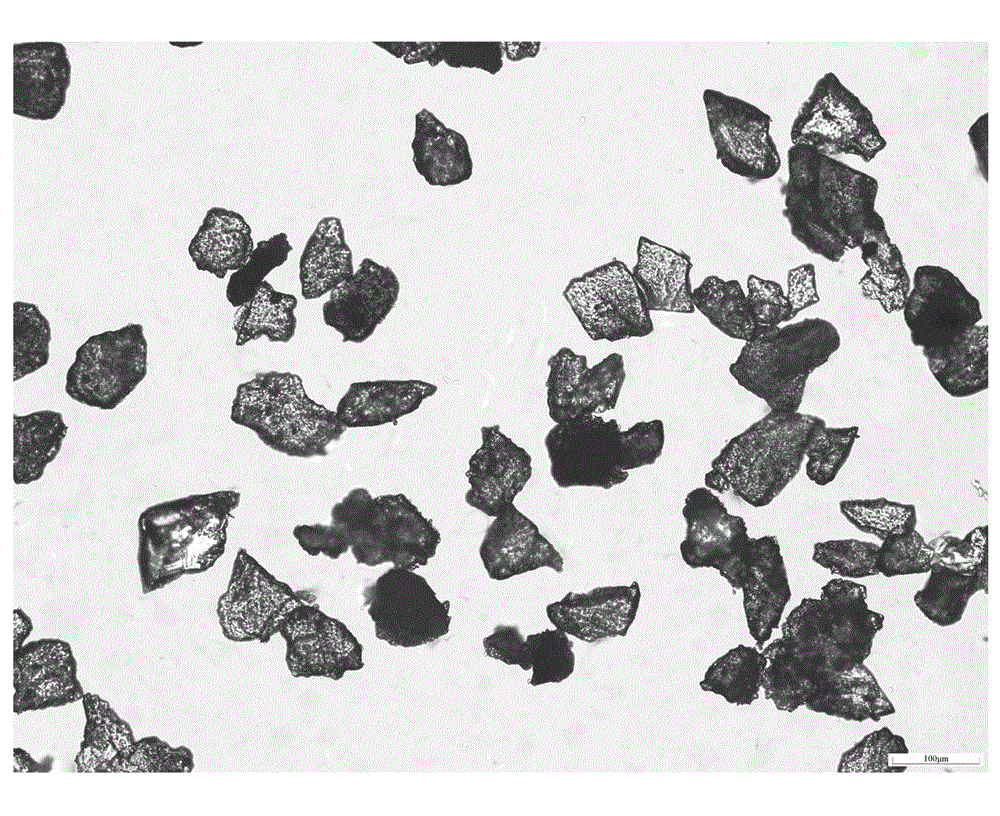

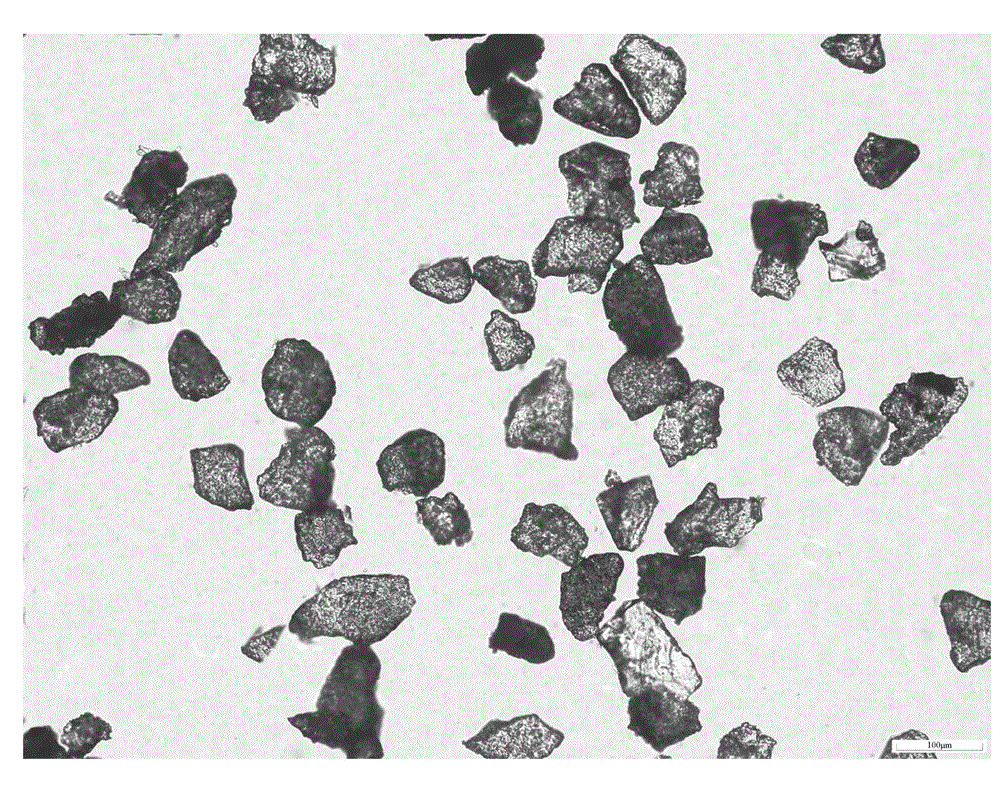

[0019] The invention can quickly make thin slices of phosphorite rock observed under a polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com