Audio signal based wind power blade damage monitoring method and system

A technology of audio signal and damage monitoring, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of tower blade defects and damages, poor working environment conditions, and difficulty in tower blade detection by non-destructive testing methods. Achieve accurate and credible monitoring results, avoid the influence of human factors, and avoid the deterioration of leaf condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

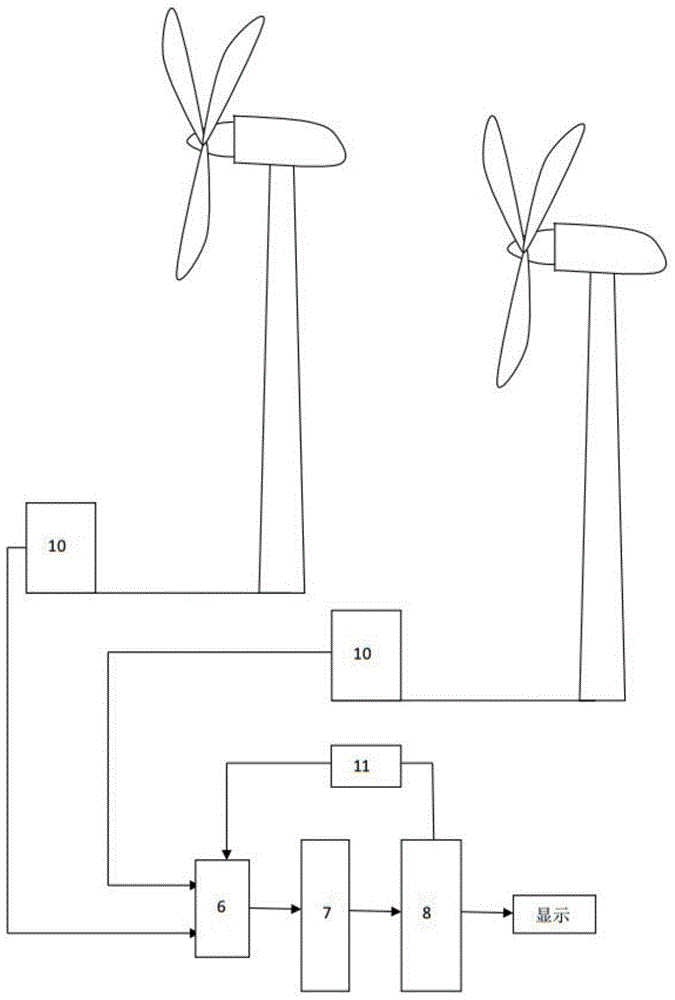

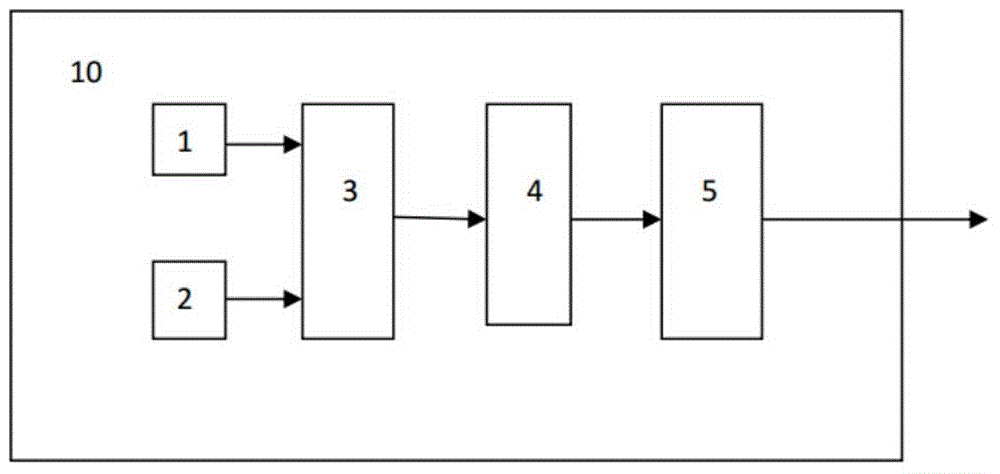

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

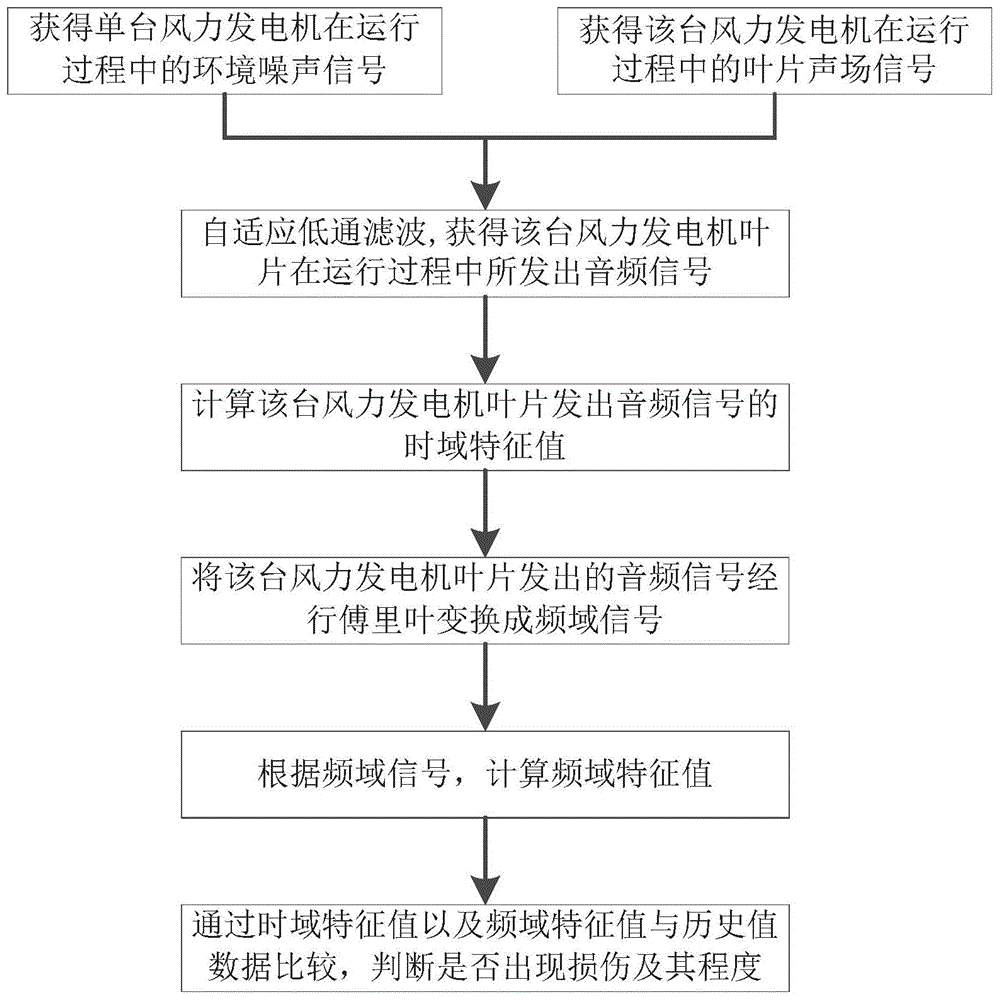

[0026] Such as figure 1 As shown, a wind turbine blade damage monitoring method includes the following steps:

[0027] (1), the ambient noise signal of a single wind turbine during operation is obtained through an omnidirectional microphone, and the blade sound field signal of the wind turbine during operation is obtained through a directional microphone;

[0028] (2), according to the obtained environmental noise signal and the sound field signal of the blade, the audio signal sent by the blade of the wind turbine during operation is obtained through adaptive low-pass filtering;

[0029] (3), calculate the time-domain eigenvalue of the audio signal sent by the wind turbine blade;

[0030] (4), carry out Fourier transform to the audio signal that this wind power generator blade sends, convert into frequency domain signal;

[0031] (5), according to the frequency dom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com