Photoelectric composite submarine cable with rated voltage 220kv

A photoelectric composite and submarine cable technology, which is applied in the direction of submarine cables, insulated cables, communication cables, etc., can solve the problems of not being able to adapt well to the submarine environment and unreasonable structural design, and achieve excellent energy saving and environmental protection, prolong service life, Effect of Good Shielding Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

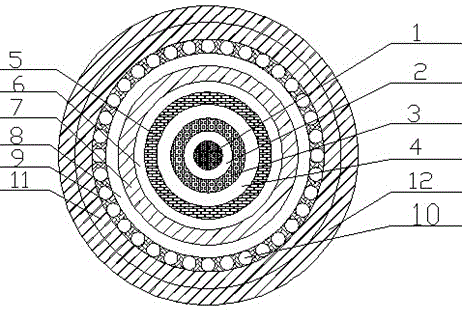

[0009] like figure 1 As shown, a photoelectric composite submarine cable with a rated voltage of 220kv includes a conductor 1, an insulating shielding layer 4 and an outer sheath 12, and the outer part of the conductor 1 is formed by extruding the conductor shielding layer 2; A layer of insulating shielding layer 4 is provided; an XLPE insulating layer 3 is arranged between the conductor shielding layer 2 and the insulating shielding layer 4; the insulating shielding layer 4 is composed of a semiconductor resistance hose 5, a lead alloy sheath 6 and The asphalt anti-corrosion layer 7 is tightly extruded; the cable is provided with a layer of outer sheath 12; the outer sheath 12 is extruded on the surface of the inner sheath 11; between the bitumen anti-corrosion layer 7 and the inner sheath 11 A layer of composite layer 9 is provided; multiple closely arranged steel tape armor strips 10 are arranged in the composite layer 9 .

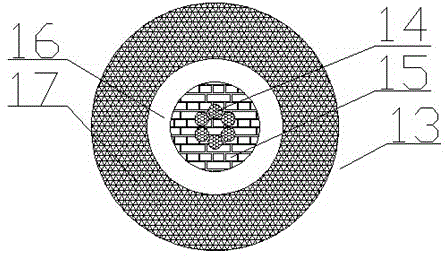

[0010] The outer layer of the rated voltage 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com