Integrated fuse

A fuse, an integrated technology, applied in the field of electrical safety protection devices, can solve the problems of improper production and assembly of melts and end caps, affecting the normal operation of the circuit, complex fuse structure, etc., achieving a simple structure and reducing the possibility of poor contact The effect of low performance, production cost and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

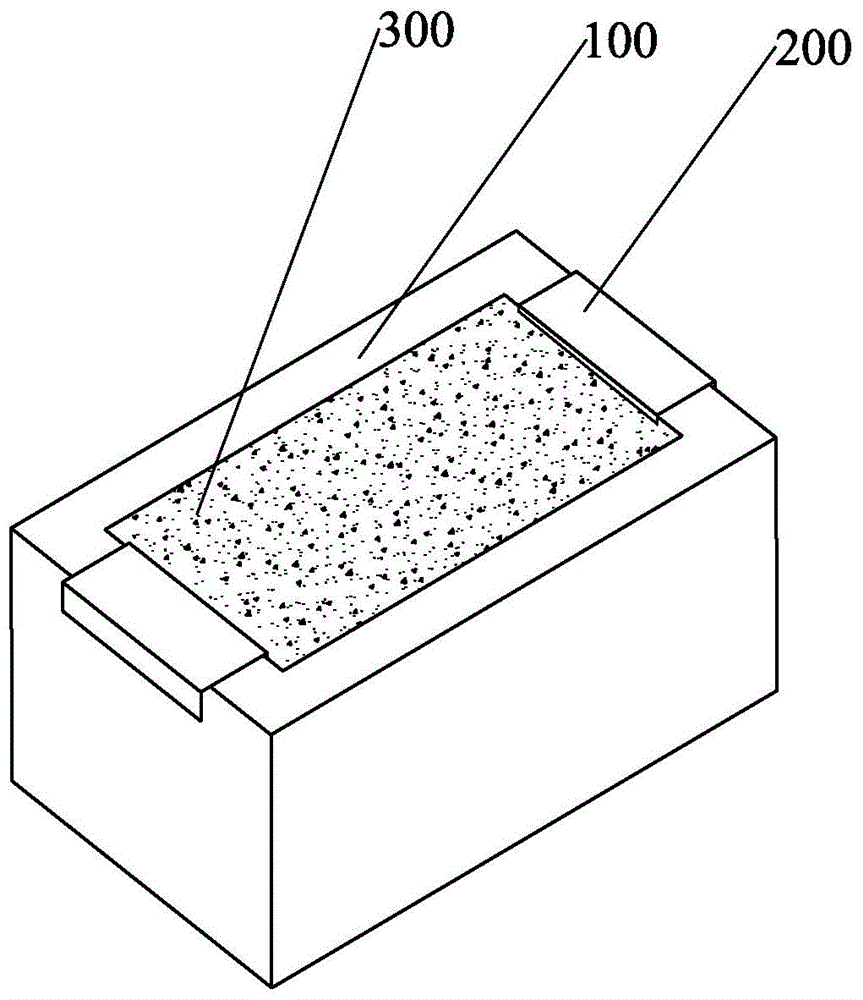

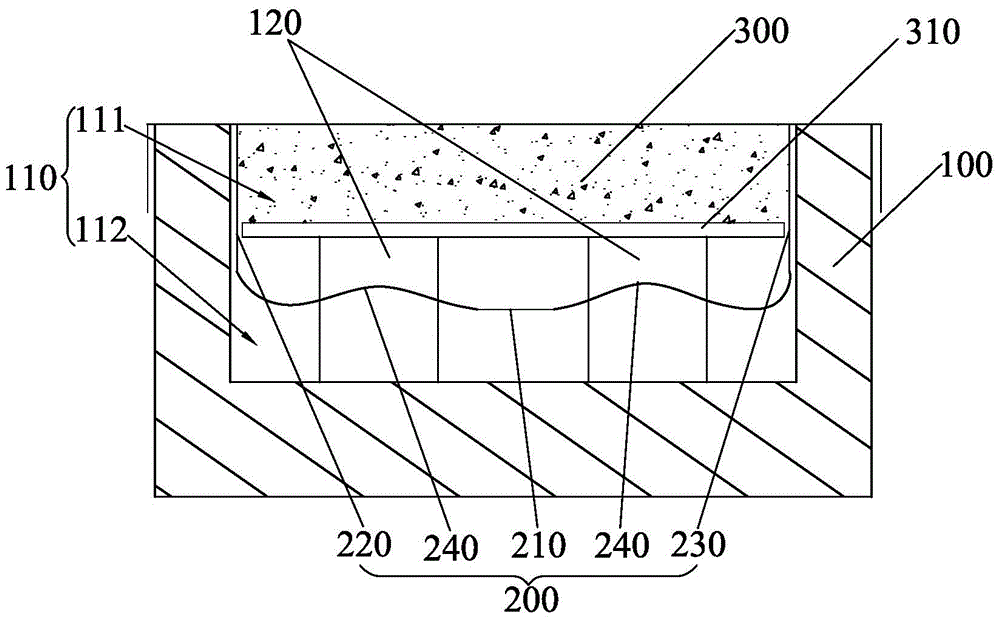

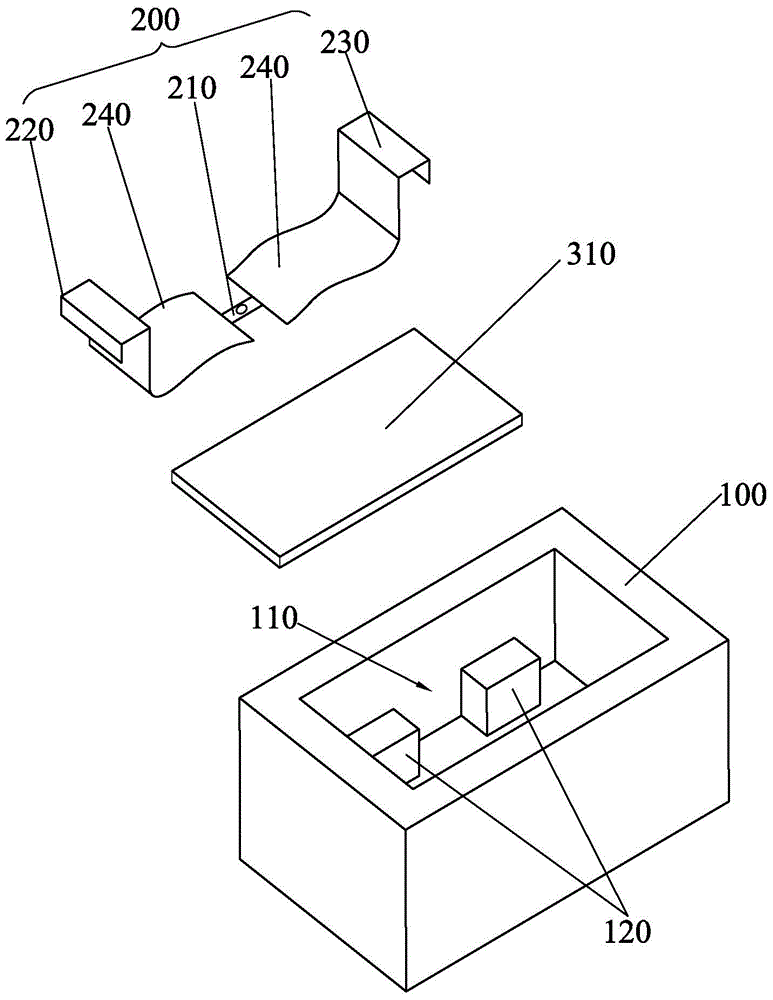

[0023] Figure 1-Figure 4 Shown is a schematic diagram of the first embodiment of the integrated fuse of the present invention.

[0024] Such as figure 1 and figure 2 The one-piece fuse shown includes an insulating case 100 , a fuse 200 and a shielding layer 300 . One side of the insulating housing 100 is recessed inwardly to form an accommodating cavity 110, so that the peripheral side of the accommodating cavity 110 is closed and only the upper part is open; the melt 200 includes a fuse part 210, a first conductive end 220 and a second conductive end 230, The fuse part 210 is disposed in the accommodating cavity 110, and the two ends of the fuse part 210 are respectively connected to the first conductive end 220 and the second conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com