Wafer defect size correction method

A technology of defect size and correction method, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve the problem of inability to obtain accurate defect size distribution, etc., to facilitate analysis and shorten a lot of time , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

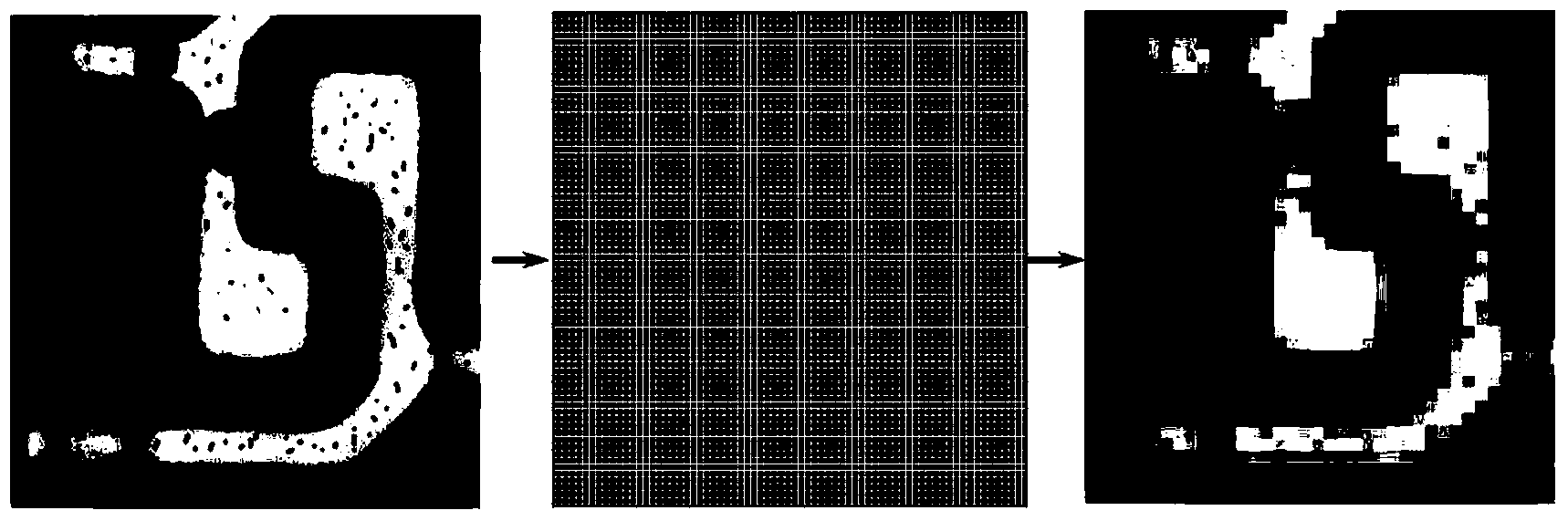

[0033] see Figure 4 , the wafer defect size correction method of the present embodiment includes the following steps:

[0034] Step S01, providing a wafer to be inspected;

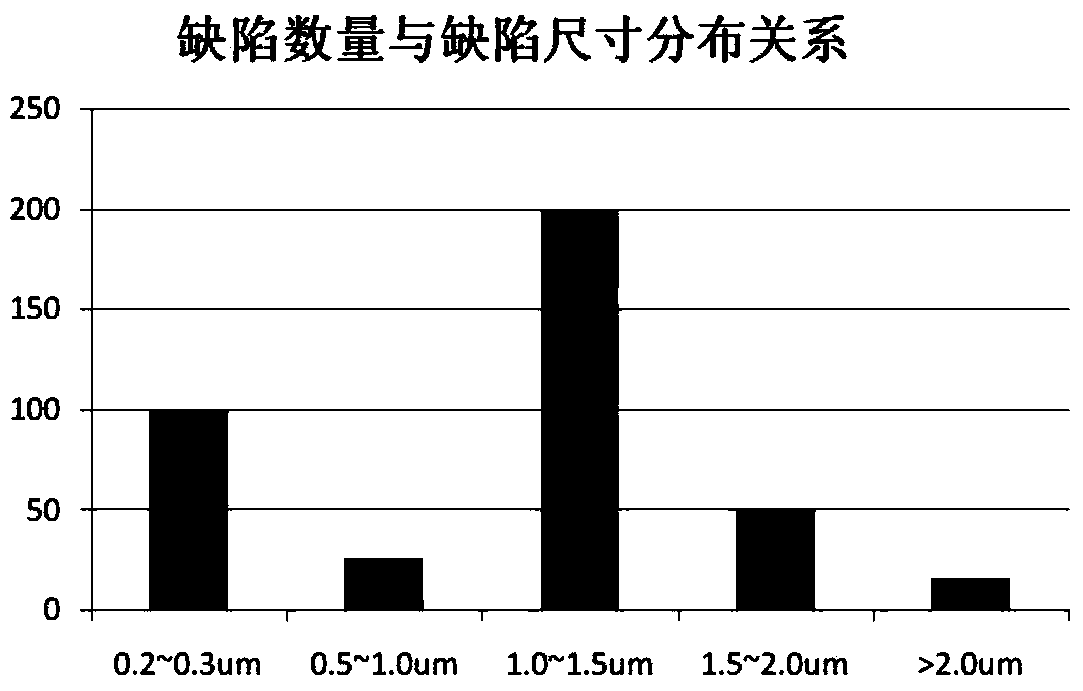

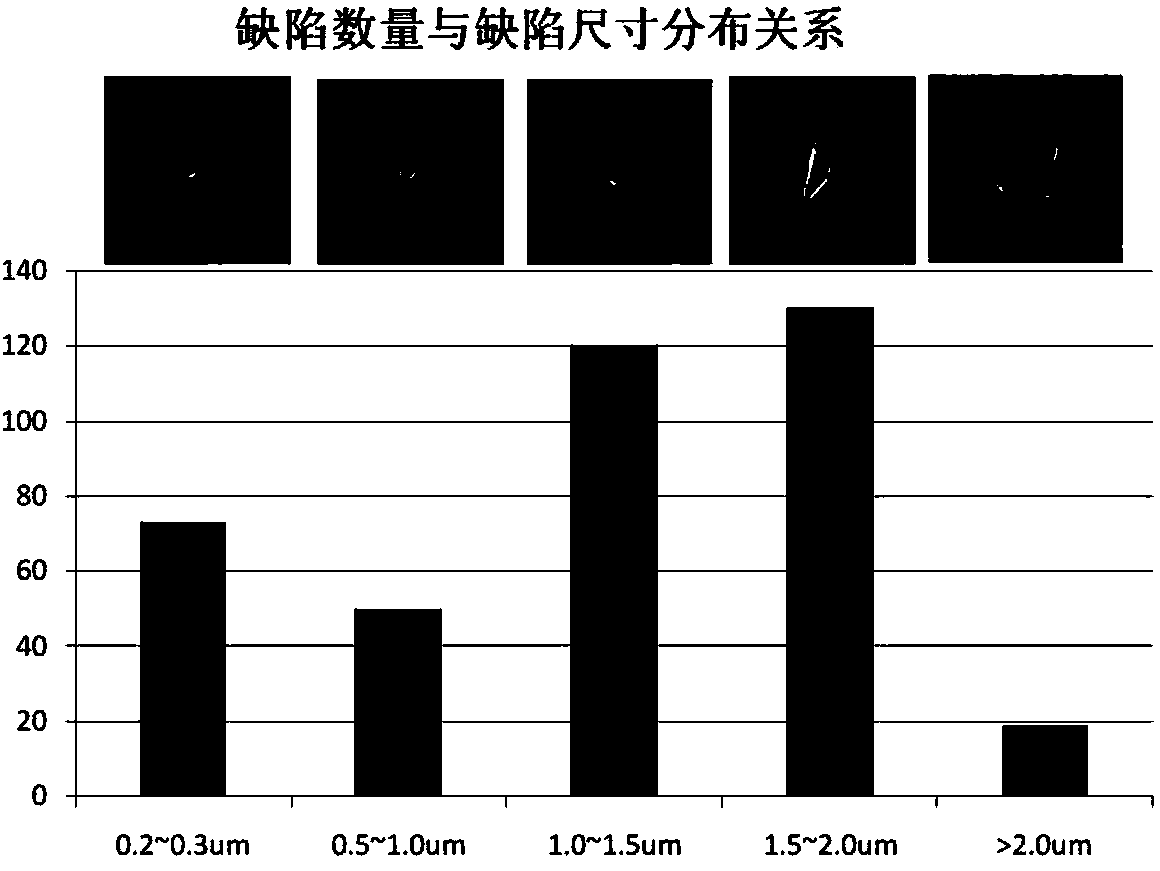

[0035] Step S02, using the defect detection equipment to perform defect detection on the region to be detected on the wafer, and selecting a number of detected defects, and obtaining the first size of the selected defects, wherein the first size is determined by the defect detection Measured by equipment;

[0036] Step S03, using defect observation equipment to observe the defect morphology of the area to be inspected, and measure the second size of the selected defects, wherein the second size is obtained by measuring the defect observation equipment;

[0037] Step S04: Based on the second size, the correction value of the first size of the plurality of defects is obtained, wherein the first size of each defect in the plurality of defects is compared with the second size one by one, and the corrected v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com