High-temperature carbon fiber heating cloth

A high-temperature carbon and carbon fiber technology, which is applied in ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of limited application range and poor high-temperature resistance, and achieve good high-temperature resistance, increased use range, and good high temperature performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

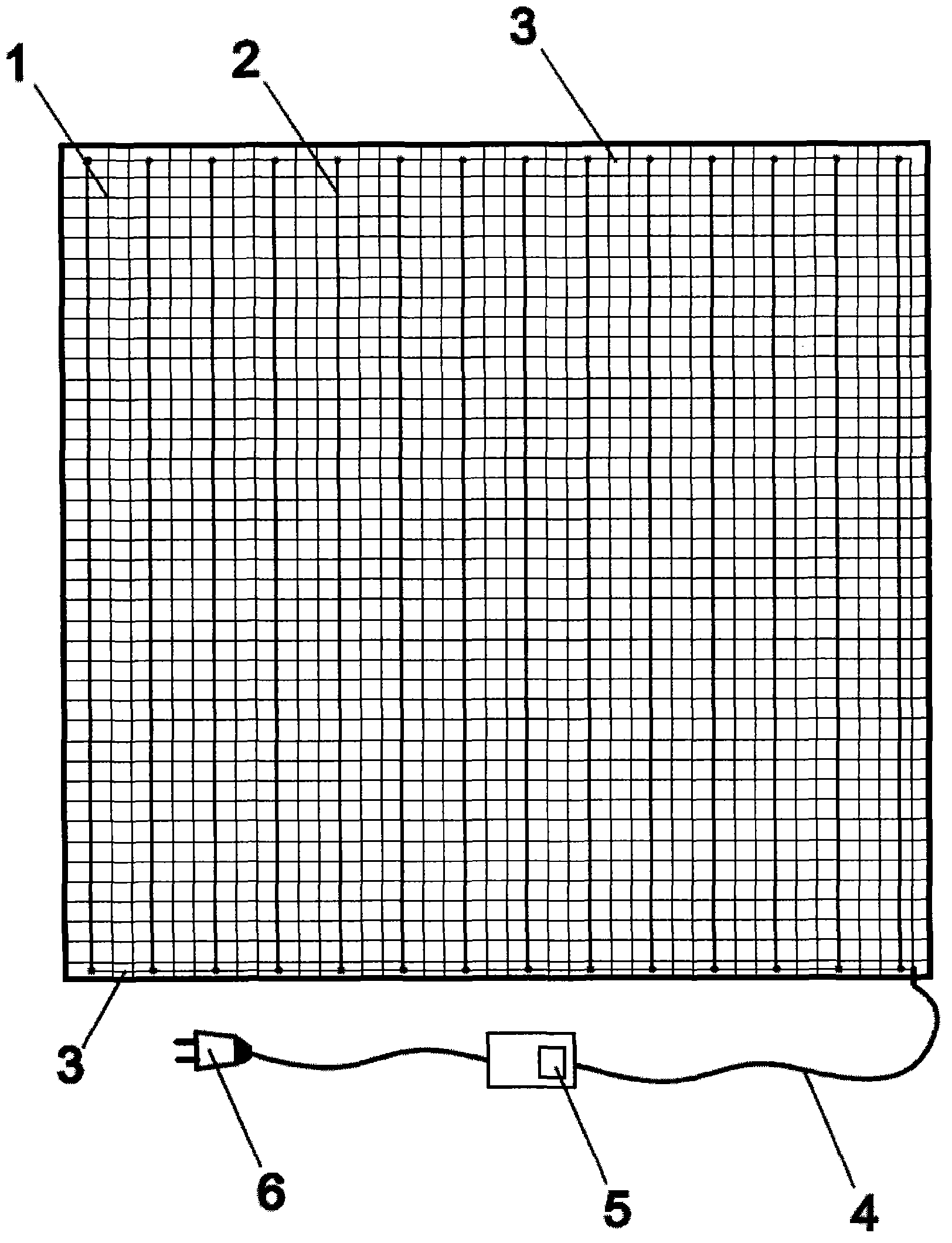

[0028] The structure diagram of the high-temperature carbon fiber heating cloth of the present invention is as follows figure 1 As shown, it includes an insulating fiber braided belt made of high-temperature insulating fibers 1 weft and weft. Several carbon fibers 2 are interspersed in parallel in the radial direction of the insulating fiber braid. The two ends of the carbon fiber 2 are connected with electrode wires 3, and the power cord 4 is connected to the electrodes At both ends of 3, the controller 5 is connected between the power plug 6 and the power cord 4.

[0029] When the carbon fiber 2 is energized, it is converted into heat energy by the carbon fiber 2 and emitted in the form of far-infrared radiation. Because the high-temperature insulating fiber 1 has good high-temperature resistance and can withstand higher temperatures, it is woven with high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com