Efficient and energy-saving type electric radiant tube heater

A technology of electric radiant tubes and heaters, applied in the direction of furnace heating elements, etc., can solve the problems of energy waste and low heating efficiency, and achieve the effects of reducing energy loss, high heating efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

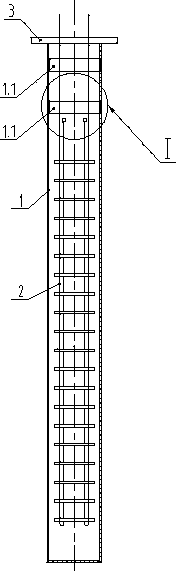

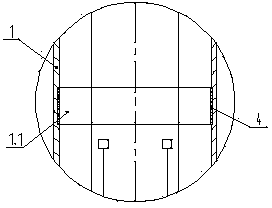

[0018] The high-efficiency and energy-saving electric radiant tube heater shown in the accompanying drawings includes a straight cylindrical radiant tube 1, a heater 2 and a flange 3 arranged in the radiant tube 1; the radiant tube 1 is located between the end of the heater 2 and the flange 3 At least one annular partition groove 1.1 is provided on the inner wall of the room, and in order to obtain a better blocking effect, the bottommost partition groove 1.1 is arranged at an axial position corresponding to the end of the heater 2; in this embodiment, the radiant tube 1 Two annular partition grooves 1.1 are provided on the inner wall between the end of the heater 2 and the flange 3 . In order to improve the partition effect, the present invention provides a high-temperature-resistant non-metallic material 4 in the partition groove 1.1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com