Preparation method of homogenized large-size silicon nitride ceramic plate

A technology of homogenization and large size is applied in the field of preparation of homogenized large size silicon nitride ceramic plates, which can solve the problems of inability to prepare dense materials and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

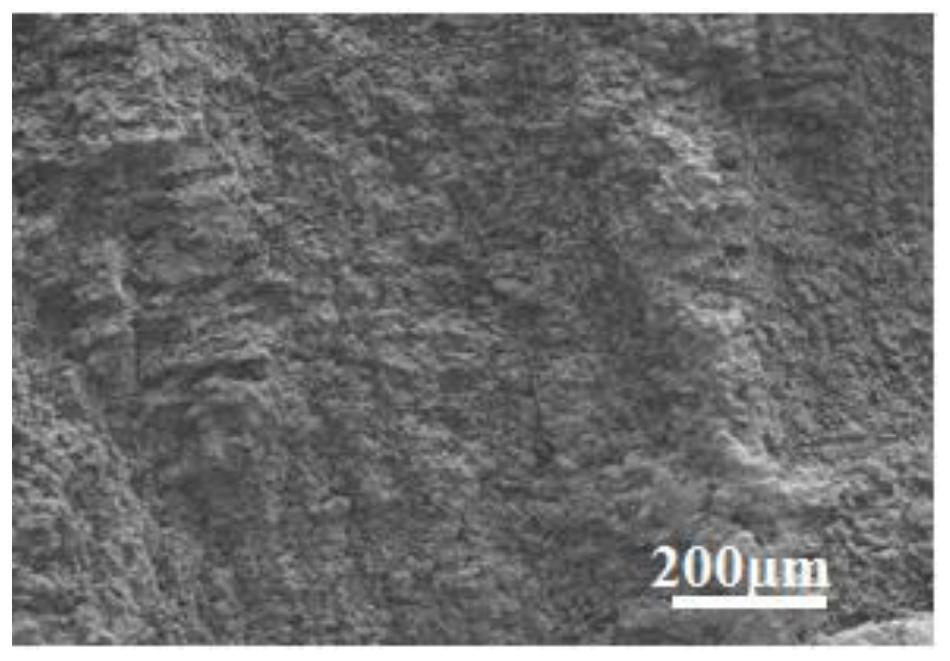

[0025] A method for preparing a homogenized large-scale silicon nitride-based ceramic flat plate, comprising the following steps:

[0026] (1) Slurry preparation: Mix silica sol, water-soluble macromolecular organic matter, sintering aid and pickled silicon nitride ceramic powder in sequence, and then ball mill to obtain slurry. The proportion of the slurry components is: silica sol 20-30wt% (can be any value within this range, such as 20wt%, 21wt%, 22wt%, 23wt%, 24wt%, 25wt%, 26wt%, 27wt%, 28wt% %, 29wt%, 30wt%), water-soluble macromolecular organic matter 2.1 ~ 4.0wt% (can be any value within this range, such as 2.1wt%, 2.5wt%, 3.0wt%, 3.5wt%, 4.0wt%) , 3.5-6.4wt% sintering aid (can be any value within this range, such as 3.5wt%, 3.6wt%, 3.7wt%, 3.8wt%, 3.9wt%, 4.0wt%), acid-washed silicon nitride Ceramic powder 70-80wt% (can be any value within this range, such as 70wt%, 71wt%, 72wt%, 73wt%, 74wt%, 75wt%, 76wt%, 77wt%, 78wt%, 79wt%, 80wt% ).

[0027]Wherein, the pH of si...

Embodiment 1

[0032] Step 1: Slurry preparation, polyvinyl alcohol, silica sol with a pH of 5.0 at a concentration of 20 wt%, acid-washed silicon nitride ceramic powder, and a sintering aid (alumina:yttrium oxide=1:3) are mixed according to a mass ratio of 4 :28:100:8: Mix evenly and ball mill to obtain silicon nitride ceramic slurry; the silicon nitride ceramic powder contains 20wt% of 0.5-0.8μm particles, 80wt% of 1-2μm particles, and the ball milling time is 60h .

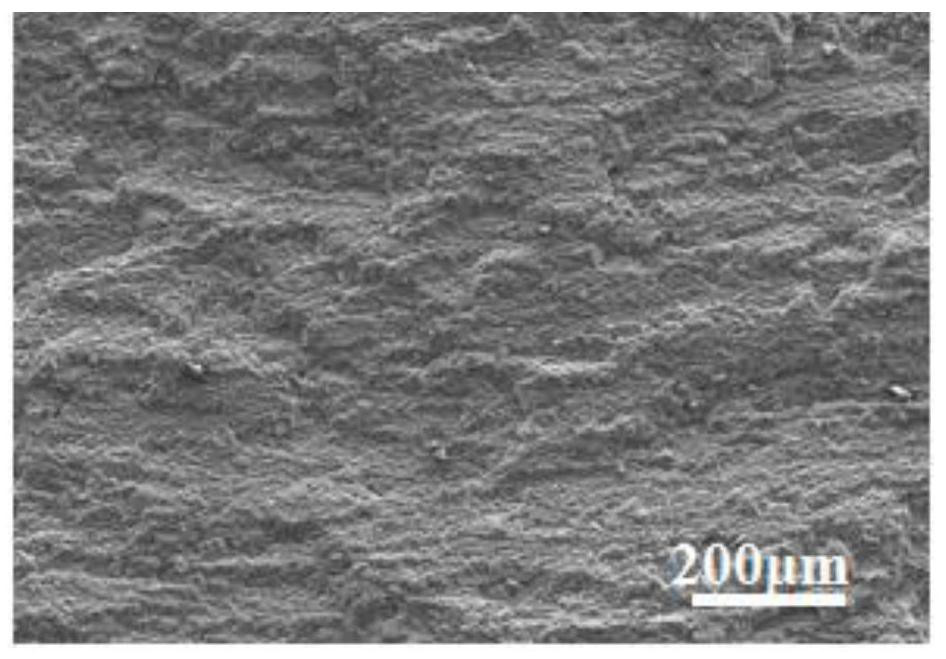

[0033] Step 2: Preparation of homogeneous silicon nitride ceramics. The above slurry is vacuum degassed for 20 minutes and poured into an aluminum mold with a bottom thickness of 3 mm (pouring time is 5 minutes), so that it is rapidly suspended in liquid nitrogen (using a liquid nitrogen tank Fix the support with a network structure and suspend) fully solidify for 1 hour and then demould to obtain a green body; dry the green body at 40°C and a humidity of 70% for 60 hours, and sinter at 1750°C for 6 hours to prepare homogeneo...

Embodiment 2

[0035] Step 1: Slurry preparation, polyvinyl alcohol and polyglycerol, silica sol with a pH of 5.5 at a concentration of 25 wt%, acid-washed silicon nitride ceramic powder, and sintering aid (aluminum oxide) in a mass ratio of 5:28:100 :6: Mix evenly and perform ball milling to obtain silicon nitride ceramic slurry; wherein the silicon nitride ceramic powder contains 15 wt% of particles of 0.5-0.8 μm, 85 wt% of particles of 1-2 μm, and the ball milling time is 96 hours.

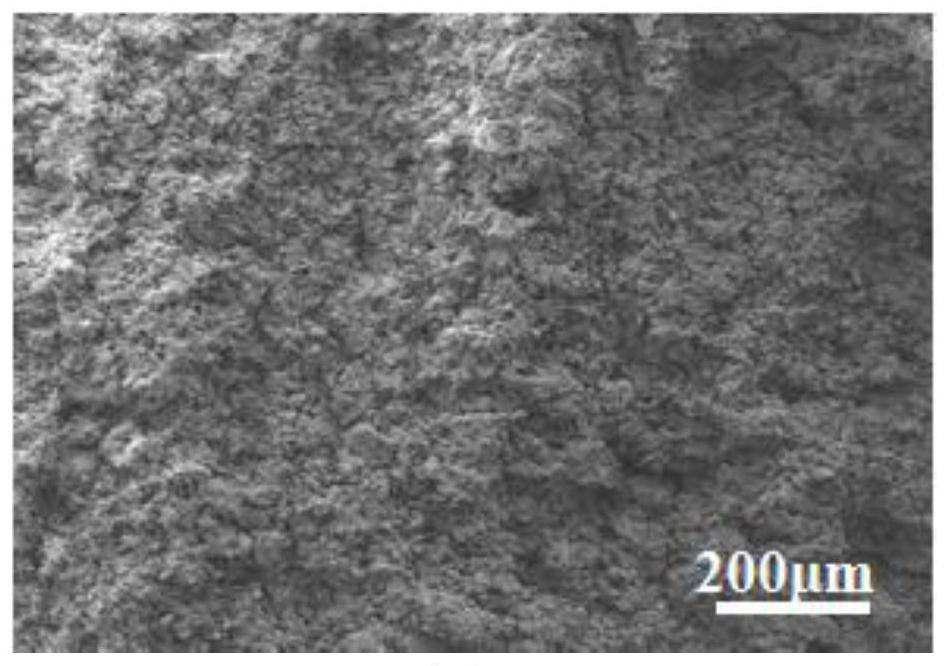

[0036] Step 2: Preparation of silicon nitride ceramics. The above-mentioned slurry is vacuum degassed for 40 minutes and poured into an aluminum mold with a bottom thickness of 4 mm (pouring time is 8 minutes), so that it is quickly suspended in liquid nitrogen and fully solidified for 2 hours before demolding to obtain a blank body; the green body was dried at 35°C and humidity 65% for 96 hours, and then sintered at 1800°C for 5 hours to prepare a homogeneous silicon nitride ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com